STRUCTURALS 5540F/YB5515 SERVICE MANUAL

11-60

4. Remove four socket head capscrews 21and

lockwashers 25. Remove motor adapter11.

5. Remove gasket 17 and shim 22. Be sure not to damage

or loose the shim.

6. Remove and discard o-ring 34.

7. Remove four capscrews 23 and lockwashers27.

Remove bearing retainer 10 and gasket19.

8. Remove and discard o-ring 34 and seal 31.

9. Using a wench on the hex on the end of the work gear

shaft 6, turn the worm shaft and walk the worm shaft and

bearings 8 and 9 out the end of the worm housing.

10. Remove bearing cones 8 and cups 9 from worm shaft 6.

11. Remove six capscrews 24 and lockwashers 26. Remove

worm gear housing cover 3 and cover gasket 20.

12. Remove retaining ring 12 and then retaining ring 14.

13. Pull worm gear 5 off of output pinion shaft 7. Remove the

remaining retaining ring 12.

14. Pull output pinion 7 from worm housing 1.

15. Remove and discard oil seal 16.

16. If necessary, remove bushing 2 from worm housing 1

and bushing 4 from worm housing cover 3.

Inspection

Clean all parts. See Section 1. Make sure breather (30,

Figure 11-128 is clean. Make a careful inspection of all parts,

including gears, shafts and bearings. Replace all seals and

gaskets.

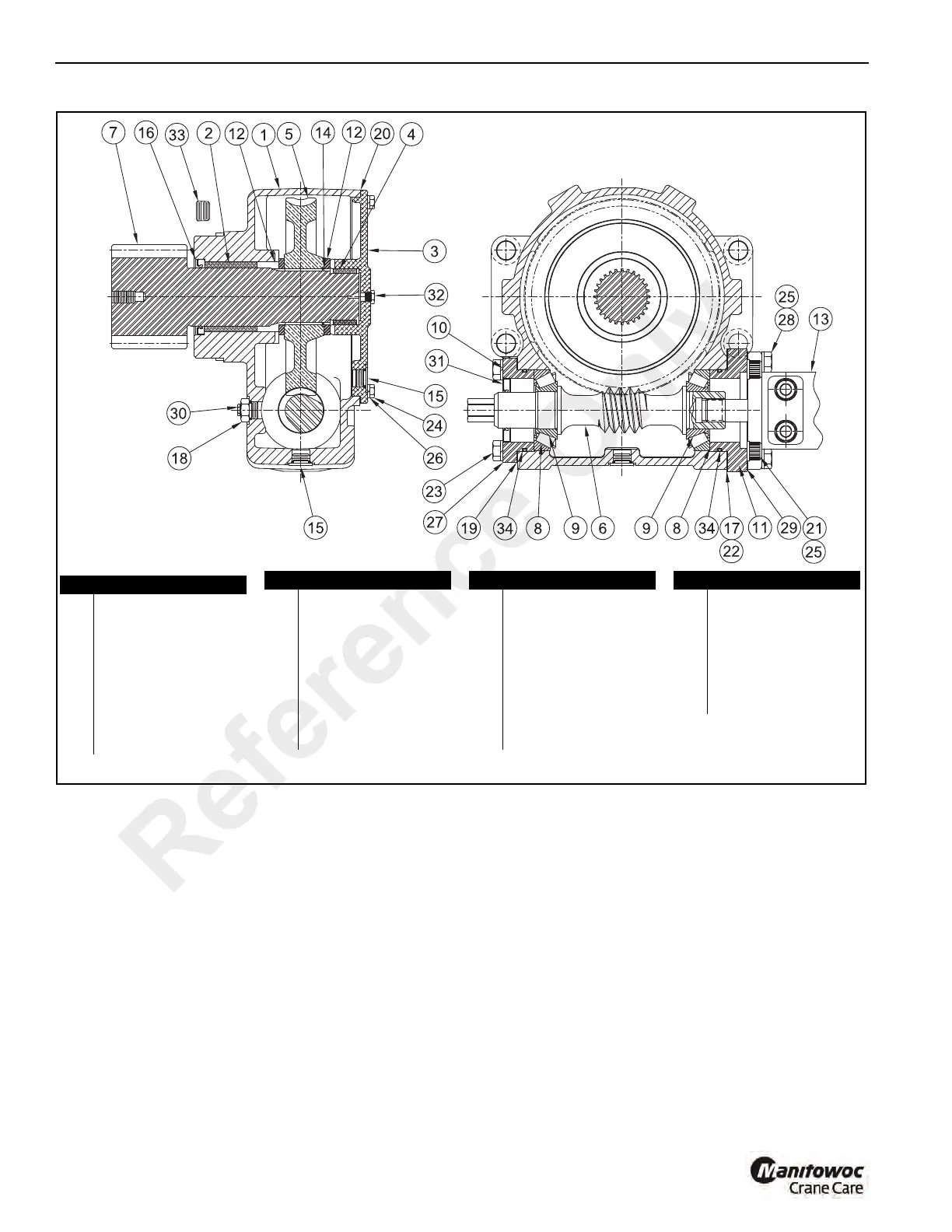

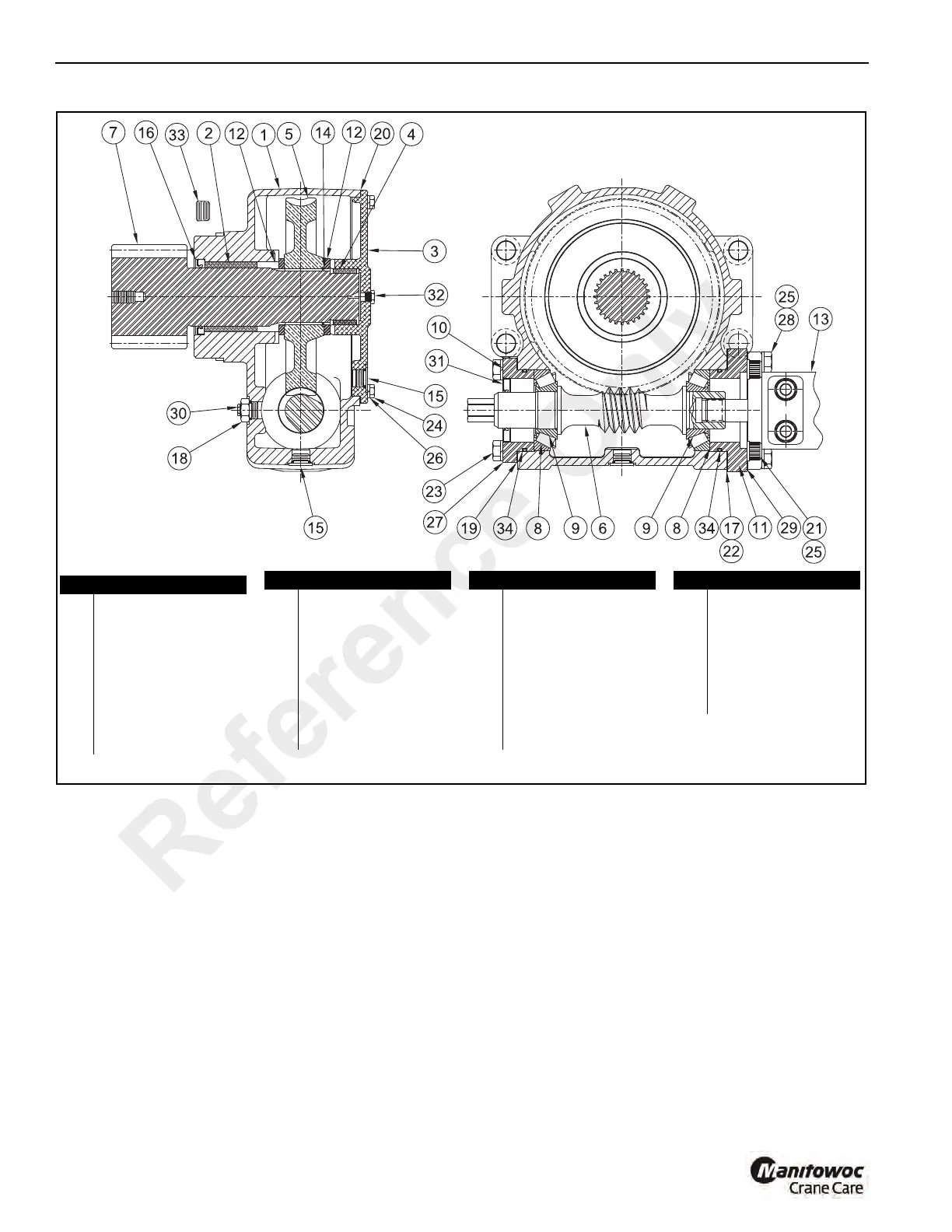

FIGURE 11-128

a2273

Winch Tension Roller Subassembly Cut-Away View

Item Description

1Worm Housing

2 Bushing

3 Worm Housing Cover

4 Bushing

5Worm Gear

6Worm

7 Output Pinion

8 Bearing Cup (2)

9 Bearing Cone (2)

10 Bearing Retainer

11 Motor Adapter

12 Retaining Ring (2)

13 Hydraulic Motor

14 Retaining Ring

15 O-Ring Plug

16 Oil Seal

17 Gasket -0.015” (4)

18 Reducer

Item Description

19 Gasket - 0.031”

20 Cover Gasket

21 Capscrew (4)

22 Shim

23 Capscrew (4)

24 Capscrew (6)

25 Lockwasher (6)

26 Lockwasher (6)

27 Lockwasher (4)

Item Description

28 Capscrew (4)

29 Motor Gasket

30 Relief Valve

31 Seal

32 Pipe Plug

33 Plug

34 O-Ring

Item Description

Reference Only

Loading...

Loading...