GROVE Published 10-21-2010, Control# 198-04 4-11

5540F/YB5515 SERVICE MANUAL HYDRAULIC SYSTEM

Test - Pump Output

To check the output of the hydraulic pump, use a 100 gpm

(379 lpm) flowmeter. Follow the instructions in the flowmeter

manual. For rated output, see page 4-1.

NOTE: All flow tests must be taken when the temperature

of the hydraulic oil is 120 - 130° F (45 - 54° C).

To check the efficiency of the pump, use the following

procedure:

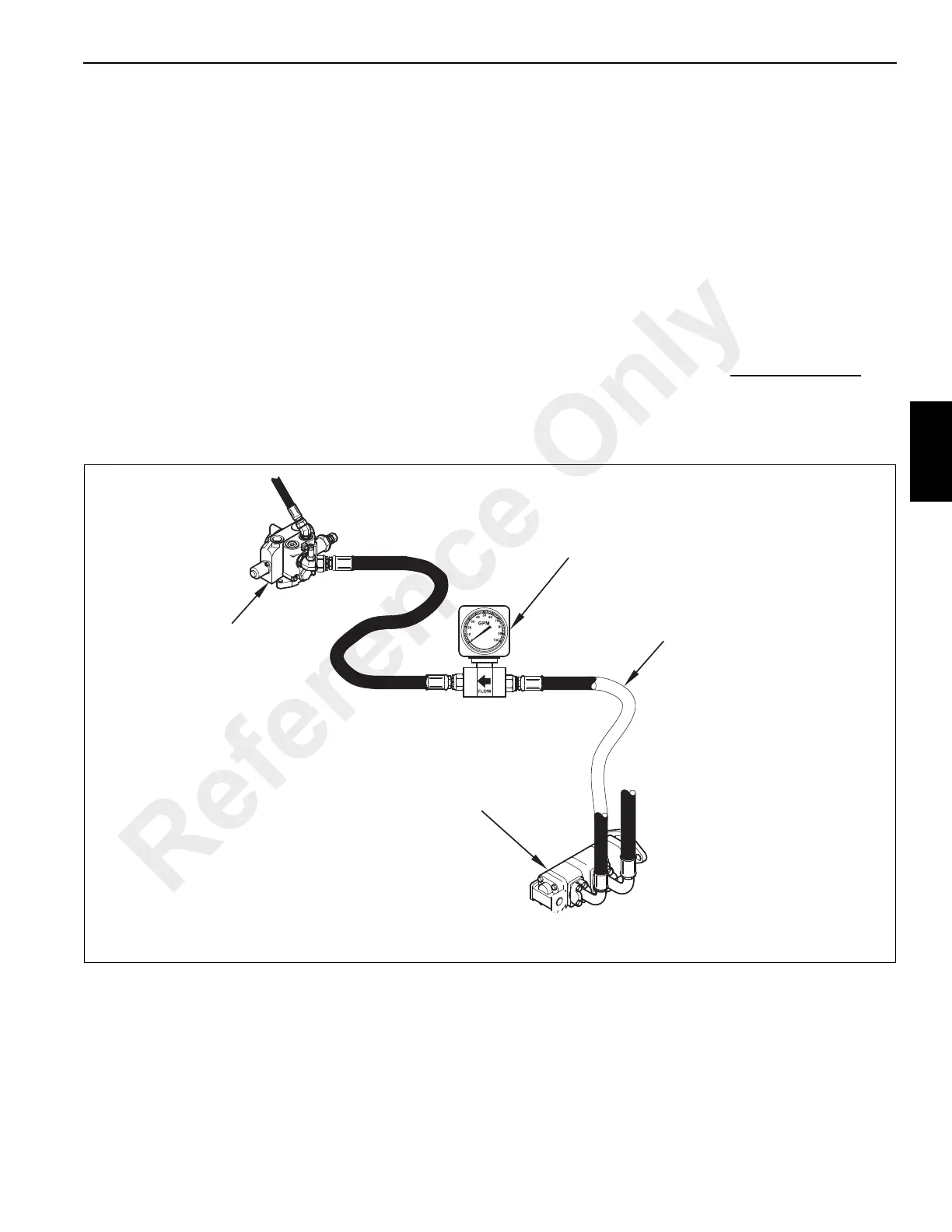

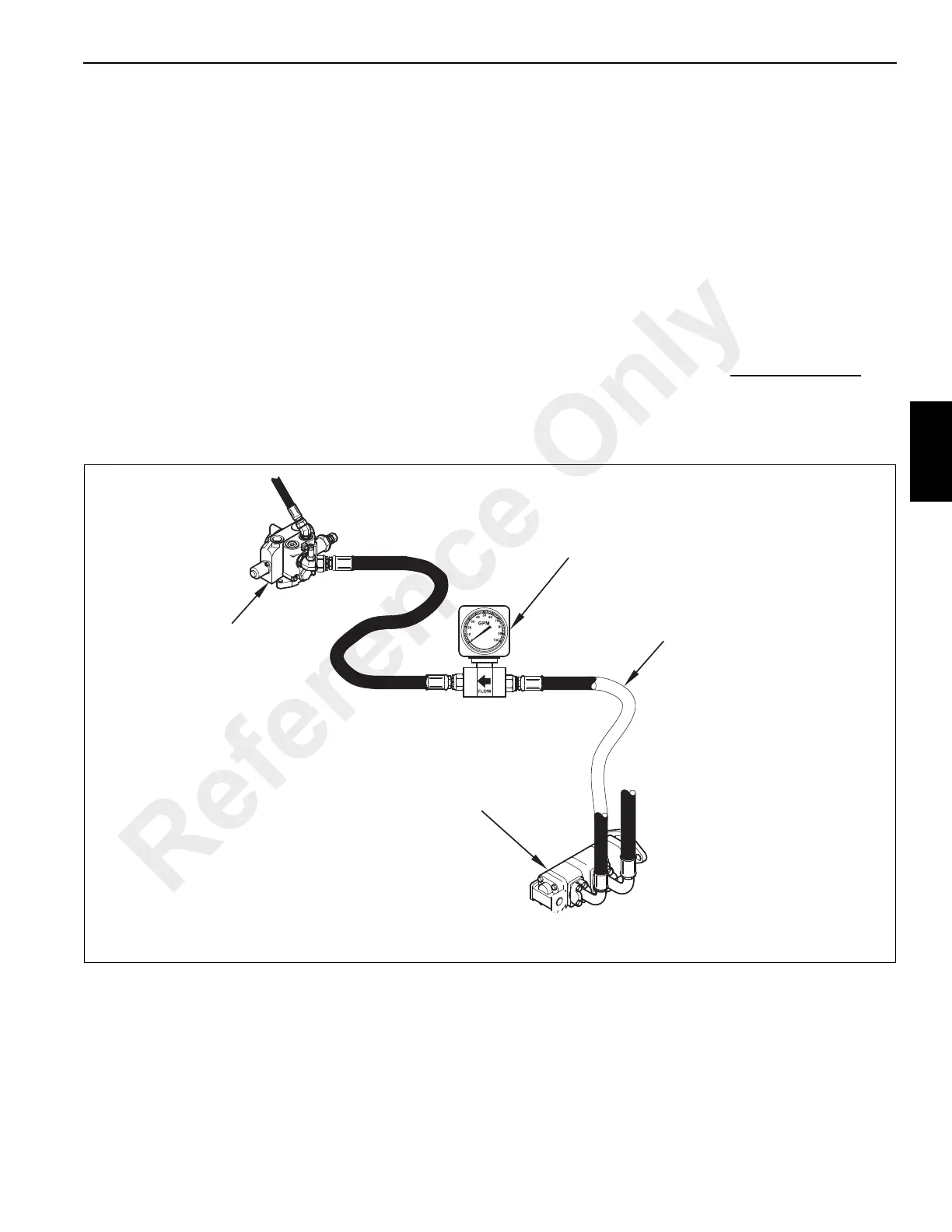

1. Connect a flowmeter between the pump and control

valve Figure 4-5 according to the instructions in the

flowmeter manual. Make sure the needle valve on the

flowmeter is fully open.

2. Start the engine and run at maximum rpm. Wait until the

oil reaches the operating temperature.

3. Slowly close the needle valve of the flowmeter until the

pressure for the circuit being supplied by the pump

section being tested.

4. Read the amount of flow on the flowmeter. Record the

flow reading and the engine rpm.

5. Fully open the flowmeter needle valve.

6. Accelerate the engine until the engine speed matches

the speed recorded in step 4. Read the amount of flow

on the flowmeter. Record this reading.

7. Compare the results to find the efficiency of the pump.

8. If the pump is less than 80% efficient, repair or

replacement is necessary.

Percent of Pump Efficiency =

Flow at 0 psi (0 kPa)

Flow at X psi

( X ) x 100

1-Spool

Control

Valve

Flowmeter

Existing Hose to

Control Valve

Hydraulic

Pump

FIGURE 4-5

a0391

Flowmeter Installation, Typical

Reference Only

Loading...

Loading...