PREVENTATIVE MAINTENANCE CD5515-2/YB5515-2 SERVICE MANUAL

5-22 Published 1-20-2017, Control# 483-02

Replace the Crankcase Oil and Filter

Change the engine oil more frequently if operating under

difficult conditions, for example in high or low temperatures,

dusty surroundings or frequent starting and stopping.

NOTE: If it is necessary to climb under the crane to change

the engine oil and replace the engine oil filter, be

sure engine is shut off, the ignition key is removed

and chock blocks are in place before climbing

under the crane.

Drain the engine oil only when it is hot and the

contaminants are in suspension.

Hot oils can cause personal injury.

1. Operate the engine until the water temperature reaches

60°C (140°F).

2. Shut off the engine

3. Place a suitable container under the engine drain plug.

Remove the oil drain plug.

4. Clean the area around the engine oil filter head.

5. Remove the filter and clean the gasket surface of the

filter head.

NOTE: The O-ring can stick on the filter head. Make sure it

is removed before installing the new filter.

6. Fill the new filter with clean recommended lubricating oil

(See engine operator’s manual furnished with the

crane).

7. Apply a small amount of clean engine oil to the gasket of

the new oil filter. Turn the filter clockwise to tighten it until

the gasket makes contact. Then, tighten the filter 1/2 to

3/4 turn to get correct seal.

8. Fill the engine crankcase with clean recommended

lubricating oil.

9. Operate the engine at idle and inspect for leaks at the

filter and drain plug

Torque Critical Bolts

NOTE: Maintain correct torque on all bolts. Failure to do so

may result in severe damage to the crane.

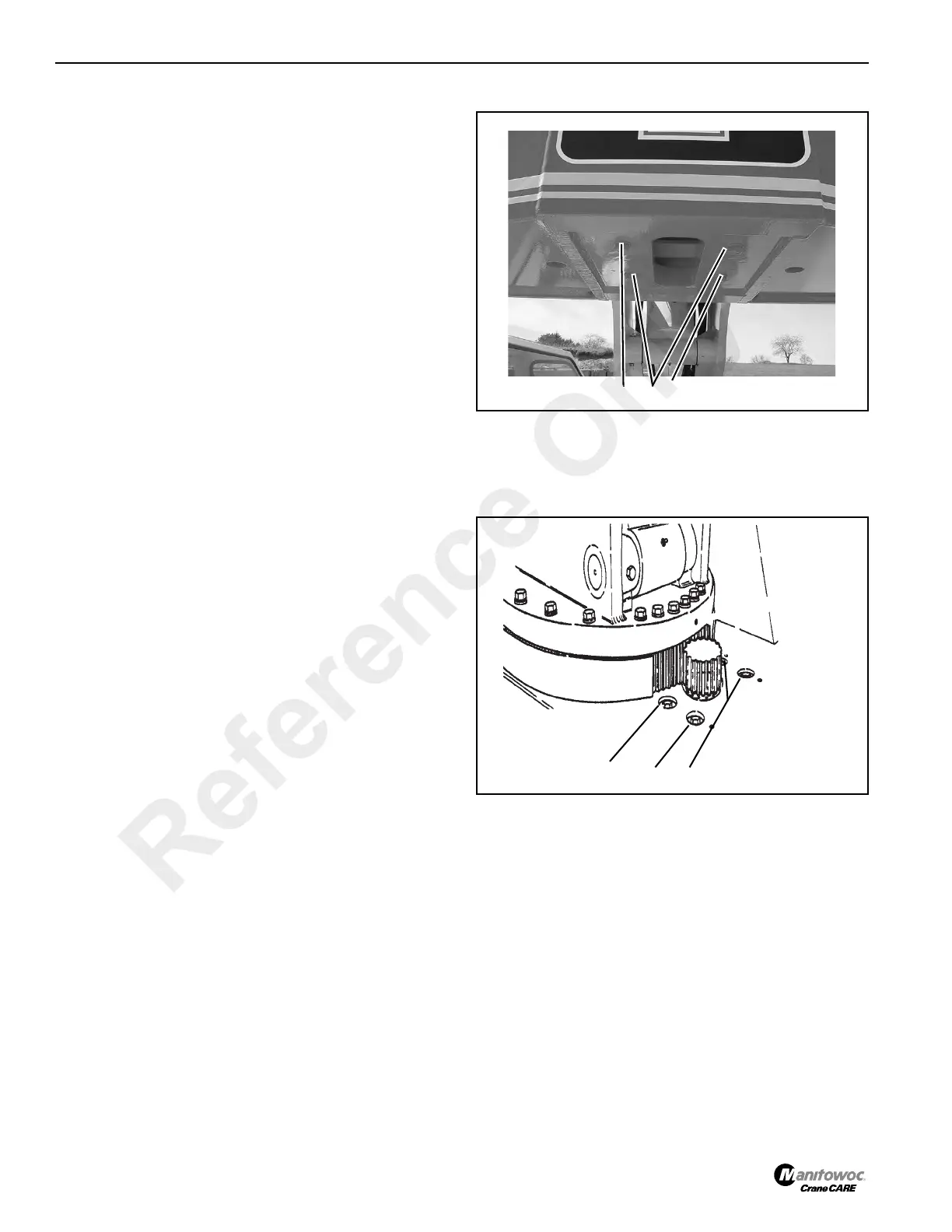

Hoist Gearbox Mounting Bolts

Torque the M16 mounting bolts (4) to 298-322 Nm (220-238

lb-ft). See Figure 5-29.

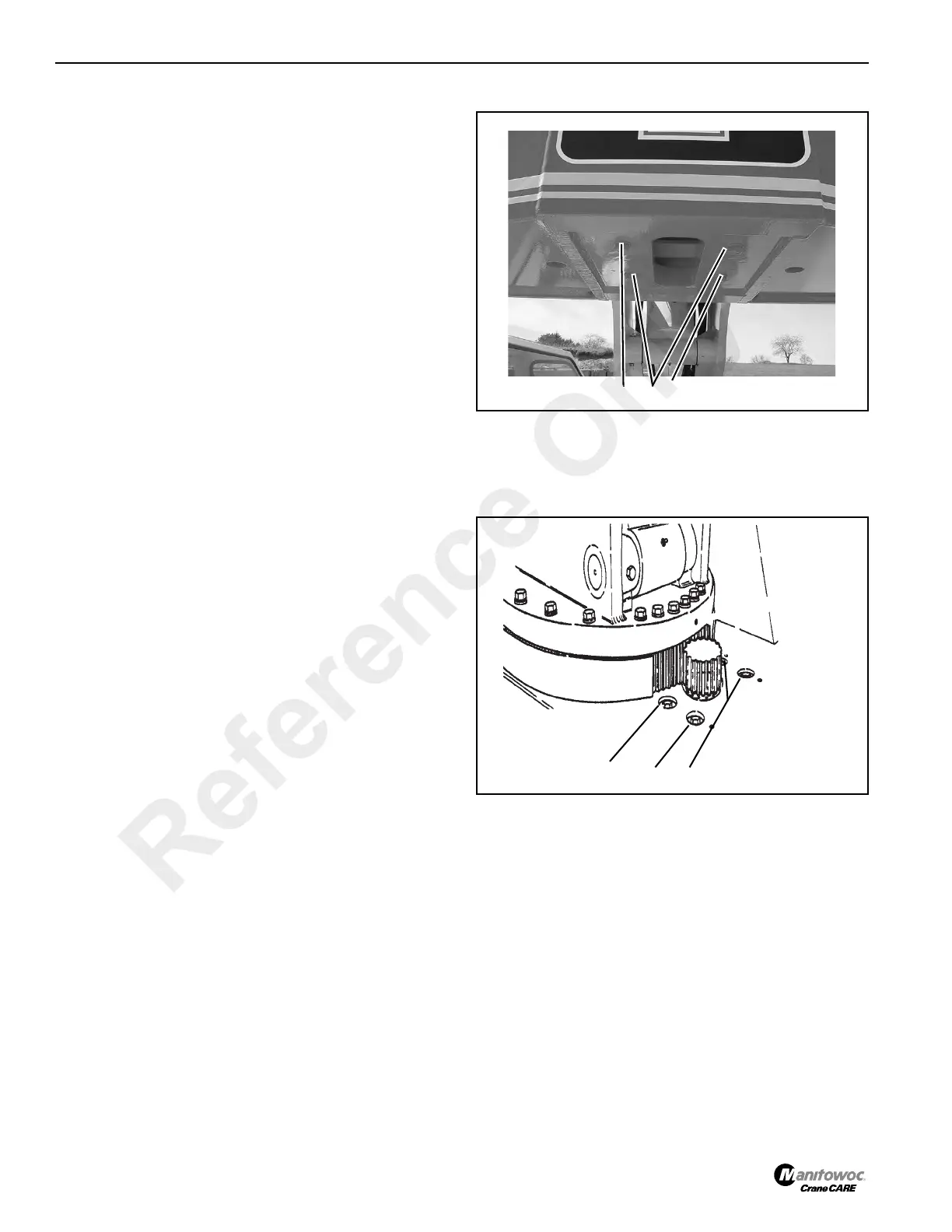

Swing Gearbox Mounting Bolts

Torque the 3/4” gearbox mounting bolts (4) to 289 Nm (213

lb-ft). See Figure 5-30. If the bolts are loose, check gear

backlash.

Mast Mounting Bolts

Because of the cyclic loading on the mast bolts, it is

important that these bolts be checked at regular intervals.

Make a record of any loose bolts. If any bolt does not hold to

correct torque after the second check, remove and replace

the bolt. A loose bolt indicates possible failure of the bolt.

The correct torque on each outside unplated bolt (mast to

swing bearing) should be 698-756 Nm (515-558 lb-ft). The

correct torque on each inside unplated bolt (swing bearing to

frame) should be 698-756 Nm (515-558 lb-ft).

Use the torque sequence shown in Figure 11-20 when

checking the torque on the bolts.

NOTE: Use only special Class 12.9 unplated bolts for

replacement of the mast bolts. Order the bolts from

your distributor, see your parts manual.

p1644

Hoist Gearbox Mounting Bolts - 4

FIGURE 5-29

Swing Gearbox Mounting Bolts

FIGURE 5-30

a0097

Reference Only

Loading...

Loading...