Installation manual - Ecotype - 51

5.4 Extraordinary maintenance work - Operations to be carried out on the customer’s covering

system

5.4.1 General tightening up of the screw connections

After the first 20/30 operating hours and later on every three months the screw connections have to be checked for

excluding any loosening on the machine and for providing the tightening up when needed.

Firmly tighten all bolts and screws of the covering!

5.4.2 Checking of the conservation status of metal structure and bows

If damages are ascertained

NOTIFY THE CUSTOMER THAT THE MACHINE REQUIRES PROBLEM-SOLVING INTERVENTION!

5.4.3 Checking of the tarpaulin conservation status

Check especially the wear and tear status of the most stressed parts like the front hooking and the lateral fixing of the bows.

5.4.4 Checking of the elastic strings or the automatic safety hooks (only if installed)

Check the conservation status of the hooking

components, if necessary provide for their

replacement.

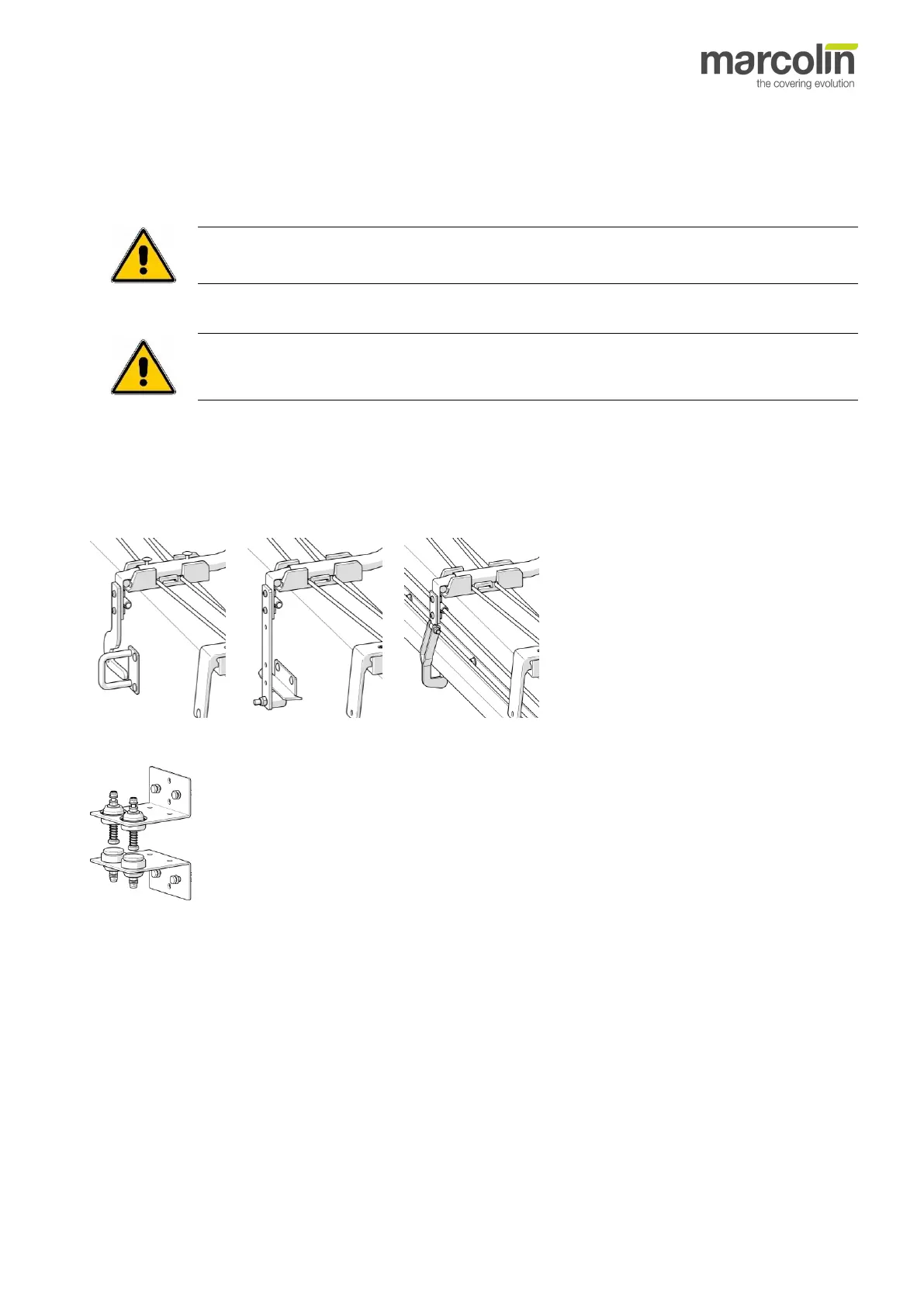

5.4.5 Checking of the contact plates (only if installed)

Check the conservation status of the contact plates (if installed, only for motorised covering system), and

if necessary provide for their cleaning.

Protect the contacts using synthetic moisture-repellent grease.

5.4.6 Checking of the sliding conditions of the tarpaulin

Check that the upper edges of the tipper body are free of damage and straight-line (absence of breaches on the locating

surface) so that the covering doesn’t hit upon any defects while sliding.

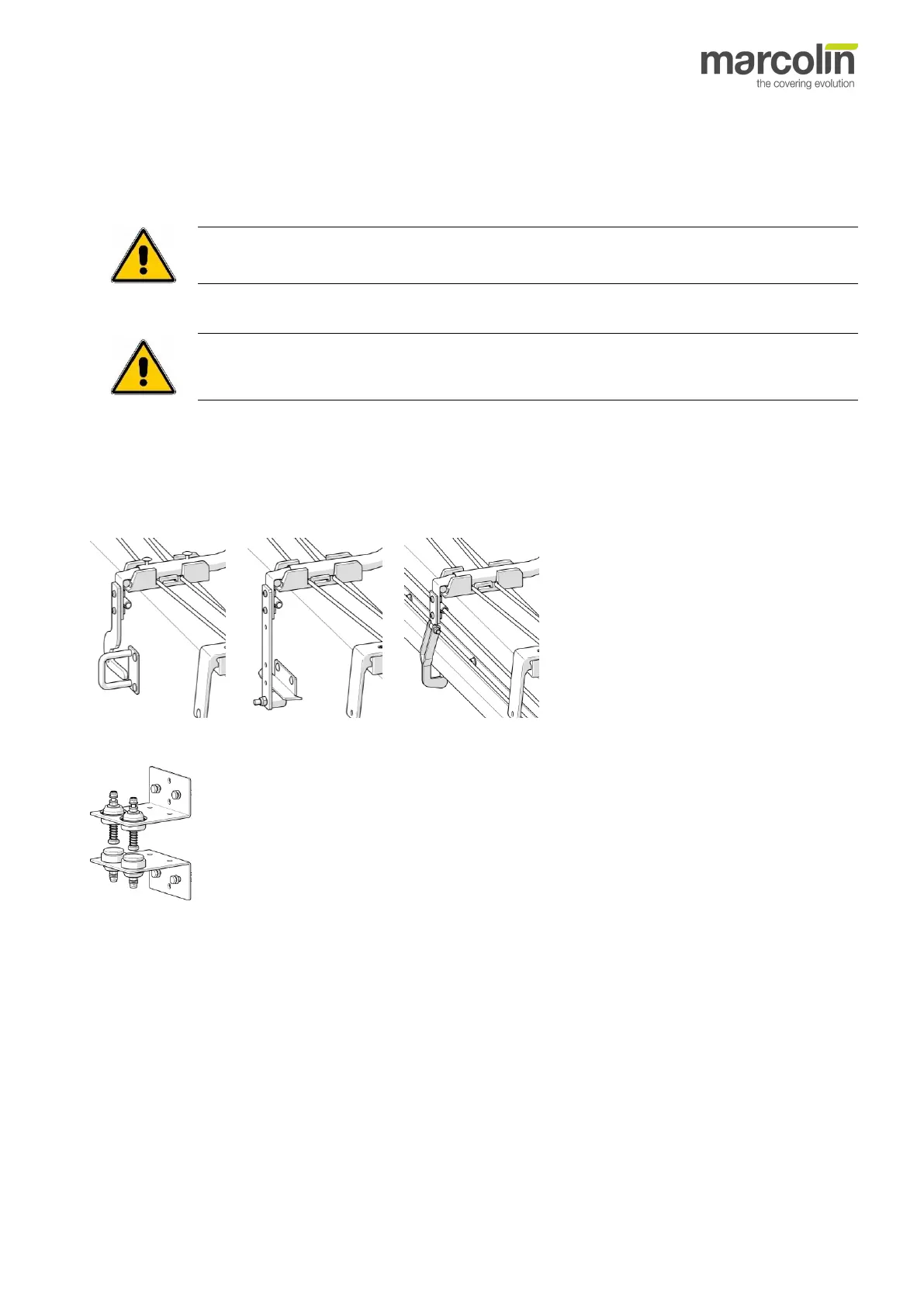

5.4.7 Thoroughly checking of the pulleys

Check that the various pulleys are free of damage so that the covering can slide properly and regularly without meeting any

anomaly.

Loading...

Loading...