T: +44 (0)1443 230935 F: +44 (0)1443 231531 E:

www.markes.com

2.4.3 The Set Gas Flow function

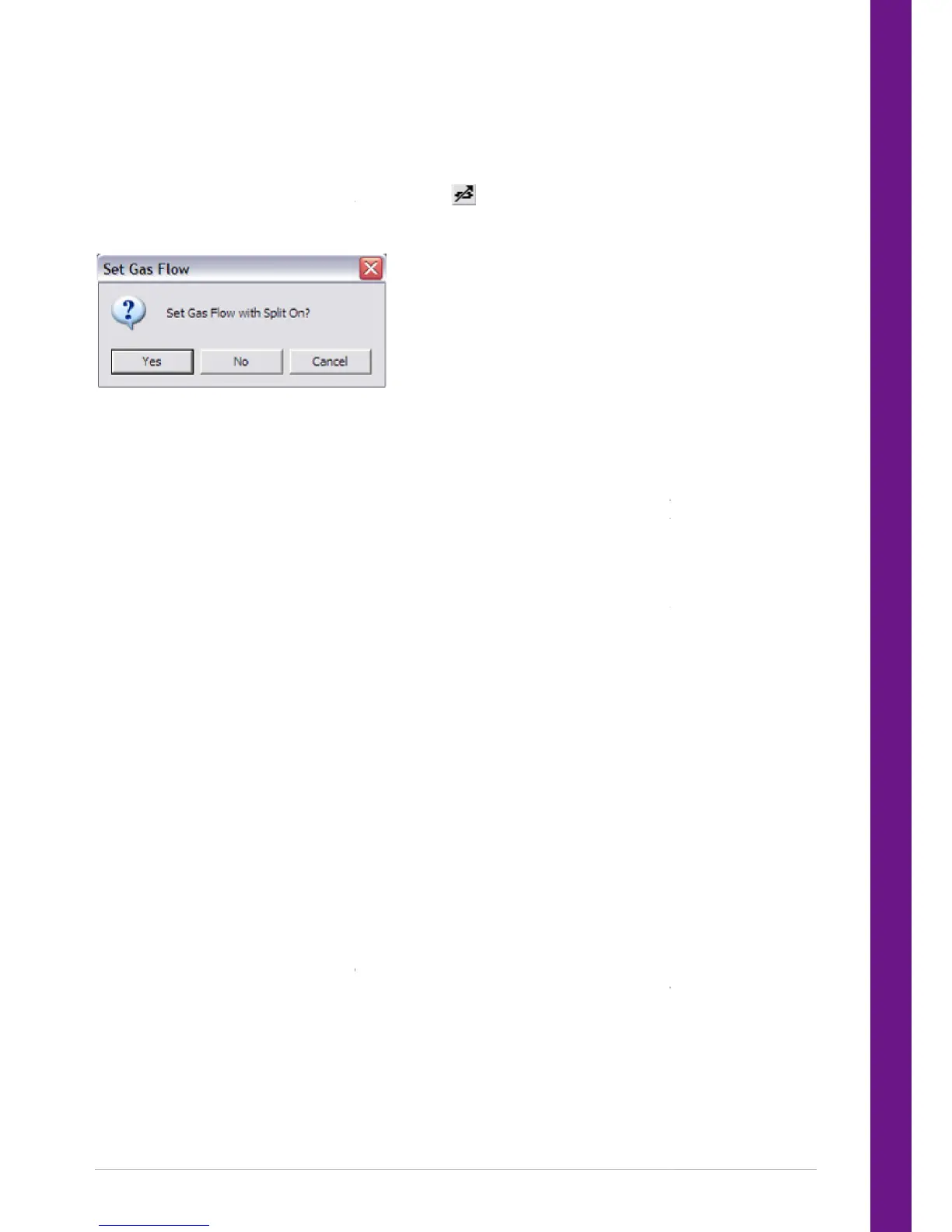

The Set Gas Flow function is accessed by selecting Instrument and then Set Gas Flow from the drop down

menu. Alternatively, click on the Set Gas Flows icon

cting Set Gas Flows a dialogue box is displayed.

If the analysis method is to include a split (single or double) then answer ‘Yes’ to the question in the box.

The UNITY 2 flow path will then alter to allow both the desorb flow and the split flow to

measured at the split and desorb flow vents.

If the analysis method is completely splitless or if only the desorb flow needs to be set, then answer ‘No’ to

the question in the box. The UNITY 2 flow path will then alter so that there is no

flow, to be adjusted and measured.

2.4.4

Measuring and adjusting flows during Set Gas Flow

A flow meter is used to measure the gas flows on UNITY 2 (non Electronic Carrier Control, ECC). A simple

bubble flow meter will suffice, howev

er a digital one is more convenient and is available from Markes

International Ltd. (C-FLMTR).

NOTE:

When UNITY 2 is setup with ECC, the flow can be read from the GC. However it can be useful to

confirm the flow readings with a flow meter. See Electronic

Most applications will require a flow meter with a minimum working range of 1 and 100 ml/min.

If a manual bubble flow meter is being used, then a stopwatch will also be required. It only m

to adjust and measure flows for the current controlling method.

To measure the flow, push the flow meter tubing over the relevant copper outlet pipe. Flows are adjusted

by turning the adjustment knob clockwise to close the needle valve and redu

to open and increase the flow.

NOTE:

The flows measured using Set Gas Flows are approximate. Approximate flows and split ratios are

sufficient for most methods, as there will be minimal run to run flow/split ratio variability

to know absolute flow rates for some reason, re

before the start of sample analysis. Measure the desorb and split flow (if applicable) during tube

desorption and the split flow again

(if applicable) during trap desorption. The split flow may be slightly

lower during trap desorption than during tube desorption because of the relatively higher impedance of

the narrow cold trap tube.

The Set Gas Flow function is accessed by selecting Instrument and then Set Gas Flow from the drop down

menu. Alternatively, click on the Set Gas Flows icon

cting Set Gas Flows a dialogue box is displayed.

If the analysis method is to include a split (single or double) then answer ‘Yes’ to the question in the box.

The UNITY 2 flow path will then alter to allow both the desorb flow and the split flow to

measured at the split and desorb flow vents.

If the analysis method is completely splitless or if only the desorb flow needs to be set, then answer ‘No’ to

the question in the box. The UNITY 2 flow path will then alter so that there is no

split flow, only the desorb

Measuring and adjusting flows during Set Gas Flow

A flow meter is used to measure the gas flows on UNITY 2 (non Electronic Carrier Control, ECC). A simple

er a digital one is more convenient and is available from Markes

When UNITY 2 is setup with ECC, the flow can be read from the GC. However it can be useful to

confirm the flow readings with a flow meter. See Electronic Carrier Control (ECC) Installation Manual for

Most applications will require a flow meter with a minimum working range of 1 and 100 ml/min.

If a manual bubble flow meter is being used, then a stopwatch will also be required. It only m

to adjust and measure flows for the current controlling method.

To measure the flow, push the flow meter tubing over the relevant copper outlet pipe. Flows are adjusted

by turning the adjustment knob clockwise to close the needle valve and reduce the flow and anticlockwise

The flows measured using Set Gas Flows are approximate. Approximate flows and split ratios are

sufficient for most methods, as there will be minimal run to run flow/split ratio variability

to know absolute flow rates for some reason, re

measure the actual flows by desorbing a blank tube

before the start of sample analysis. Measure the desorb and split flow (if applicable) during tube

(if applicable) during trap desorption. The split flow may be slightly

lower during trap desorption than during tube desorption because of the relatively higher impedance of

The Set Gas Flow function is accessed by selecting Instrument and then Set Gas Flow from the drop down

If the analysis method is to include a split (single or double) then answer ‘Yes’ to the question in the box.

The UNITY 2 flow path will then alter to allow both the desorb flow and the split flow to

If the analysis method is completely splitless or if only the desorb flow needs to be set, then answer ‘No’ to

split flow, only the desorb

A flow meter is used to measure the gas flows on UNITY 2 (non Electronic Carrier Control, ECC). A simple

er a digital one is more convenient and is available from Markes

When UNITY 2 is setup with ECC, the flow can be read from the GC. However it can be useful to

Carrier Control (ECC) Installation Manual for

Most applications will require a flow meter with a minimum working range of 1 and 100 ml/min.

If a manual bubble flow meter is being used, then a stopwatch will also be required. It only m

To measure the flow, push the flow meter tubing over the relevant copper outlet pipe. Flows are adjusted

ce the flow and anticlockwise

The flows measured using Set Gas Flows are approximate. Approximate flows and split ratios are

sufficient for most methods, as there will be minimal run to run flow/split ratio variability

measure the actual flows by desorbing a blank tube

before the start of sample analysis. Measure the desorb and split flow (if applicable) during tube

(if applicable) during trap desorption. The split flow may be slightly

lower during trap desorption than during tube desorption because of the relatively higher impedance of

Loading...

Loading...