Code F07011709

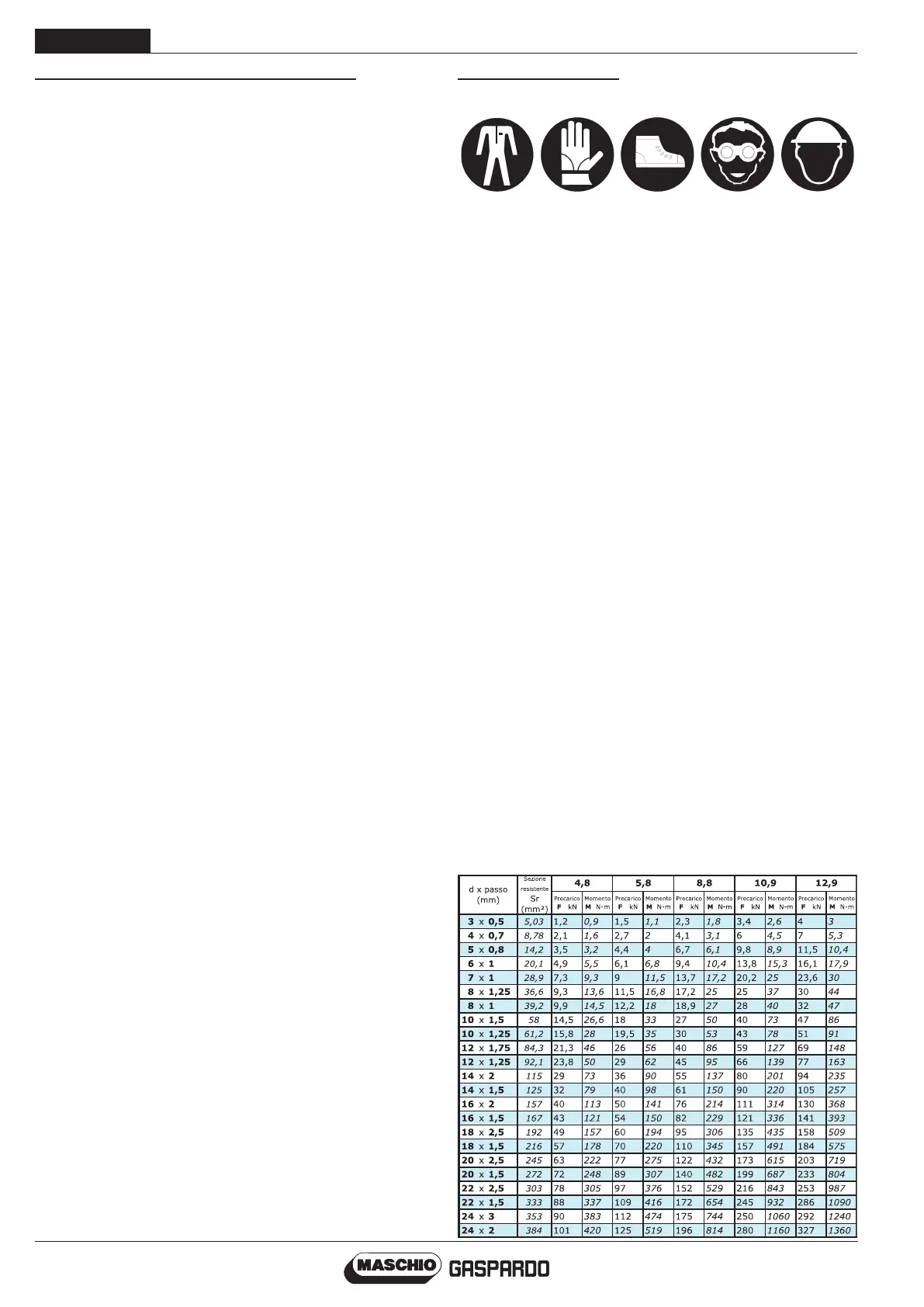

Table SV1

Sicurezza relativa all’idraulica

1) Al momento dell’allacciamento dei tubi idraulici all’im-

pianto idraulico del trattore, fare attenzione che gli im-

pianti idraulici della macchina operatrice e della trattrice

non siano in pressione.

2) In caso di collegamenti funzionali di tipo idraulico tra trat-

trice e macchina operatrice, prese e spine dovrebbero

essere contrassegnate per mezzo di colori, in modo da

escludere impieghi errati. Ove si vericasse uno scam-

bio, sussisterebbe il pericolo di incidente.

3) L’impianto idraulico si trova sotto alta pressione; a causa

del pericolo d’infortunio, in caso di ricerca di punti di

perdita vanno utilizzati gli strumenti ausiliari idonei.

4) Non effettuare MAI la ricerca perdite con le dita o le mani.

I liquidi che fuoriescono dai forellini possono essere

quasi invisibili.

5) Durante il trasporto su strada i collegamenti idraulici fra

trattrice e macchina operatrice devono essere scollegati

e ssati nell’apposito supporto.

6) Non utilizzare in alcun caso olii vegetali. Questi potreb-

bero provocare rischi di danneggiamento alle guarnizioni

dei cilindri.

7) Le pressioni di esercizio dell’impianto oleodinamico

devono essere comprese tra le 100 bar e le 180 bar.

8) Mai superare la pressione prevista dell’impianto oleodi-

namico.

9) Vericare il corretto innesto degli attacchi rapidi, si

potrebbero vericare danneggiamenti ai componenti

dell’impianto.

10) La fuoriuscita di olio ad alta pressione può causare ferite

cutanee con il rischio di gravi ferite ed infezioni. In tal

caso consultare immediatamente un medico. Se non si

rimuove rapidamente l’olio con mezzi chirurgici, posso-

no vericarsi gravi allergie e/o infezioni. Quindi si vieta

assolutamente di installare componenti oleodinamici

nella cabina del trattore. Tutti i componenti facenti parte

dell’impianto, vanno accuratamente sistemati per evitare

danneggiamenti durante l’utilizzo dell’attrezzatura.

11) In caso di intervento sull’impianto oleodinamico, scari-

care la pressione oleodinamica portando tutti i comandi

idraulici in tutte le posizioni alcune volte dopo aver

spento il motore.

USE AND MAINTENANCE

ENGLISH

14

Maintenance in safety

During work and maintenance operations, use suitable

personal protection gear:

Overalls Gloves Shoes Goggles Hardhat

1) Do not proceed with maintenance and cleaning if the

power take-off has not been disconnected rst, the

engine power off, the hand brake pulled and the tractor

blocked with a wooden block or stone of the right size

under the wheels.

2) Periodically check that the bolts and nuts are tight, and

if necessary tighten them again. For this it would be

advisable to use a torque wrench, respecting the values

of 53 Nm for M10 bolts, resistance class 8.8, and 150

Nm for M14 bolts resistance class 8.8 (Table SV1).

3) During assembling, main-tenance, cleaning, fitting,

etc., with the seeding machine raised, place adequate

supports under the equipment as a precaution.

4) The spare parts must correspond to the manufacturer’s

specications. Use only original spares.

Safety measures concerning the hydraulics

1) At the moment of connecting the hydraulic tubes to

the hydraulic system of the tractor, make sure that the

hydraulic systems of the operating machine and the

tractor are not under pressure.

2) For the operative hydraulic connections between tractor

and operating machine, the sockets and plugs should

be marked with colours to distinguish them, to avoid

them being used wrongly. There would be a danger of

accident if the connections were to be swapped round.

3) The hydraulic system is under high pressure; because

of the accident risk, when searching for leakage points

special auxiliary instruments should be used.

4) Not to never carry out the search losses with the ngers

or the hands. The liquids that exit from the holes can be

nearly not visible.

5) During transport by road the hydraulic connections

between tractor and operating machine should be di-

sconnected and secured to the support provided.

6) Do not use vegetable oils under any circumstance. These

could cause a risk of damage to the cylinder gaskets.

7) The operating pressures of the hydraulic system should

be between 100 bars and 180 bars.

8) Never exceed the indicated hydraulic system pressure

levels.

9) Check that the quick hook-ups are coupled correctly;

parts of the system could get damaged if they are not.

10) Oil escaping at high pressure can cause skin injury

with the risk of serious wounds and infection. Call a

doctor immediately if such an incident occurs. If the oil

with surgical means is not removed quickly, can take

place serious allergies and/or infections. Therefore,

the installation of hydraulic components in the tractor

driver’s cab is strictly forbidden. All the components of

the system should be positioned carefully to avoid parts

being damage during use of the equipment.

11) In case of participation on the hydraulic system, to

unload the hydraulic pressure carrying all the hydraulic

commandos in all the positions some times after to have

extinguished the motor.

Loading...

Loading...