Code F07011709

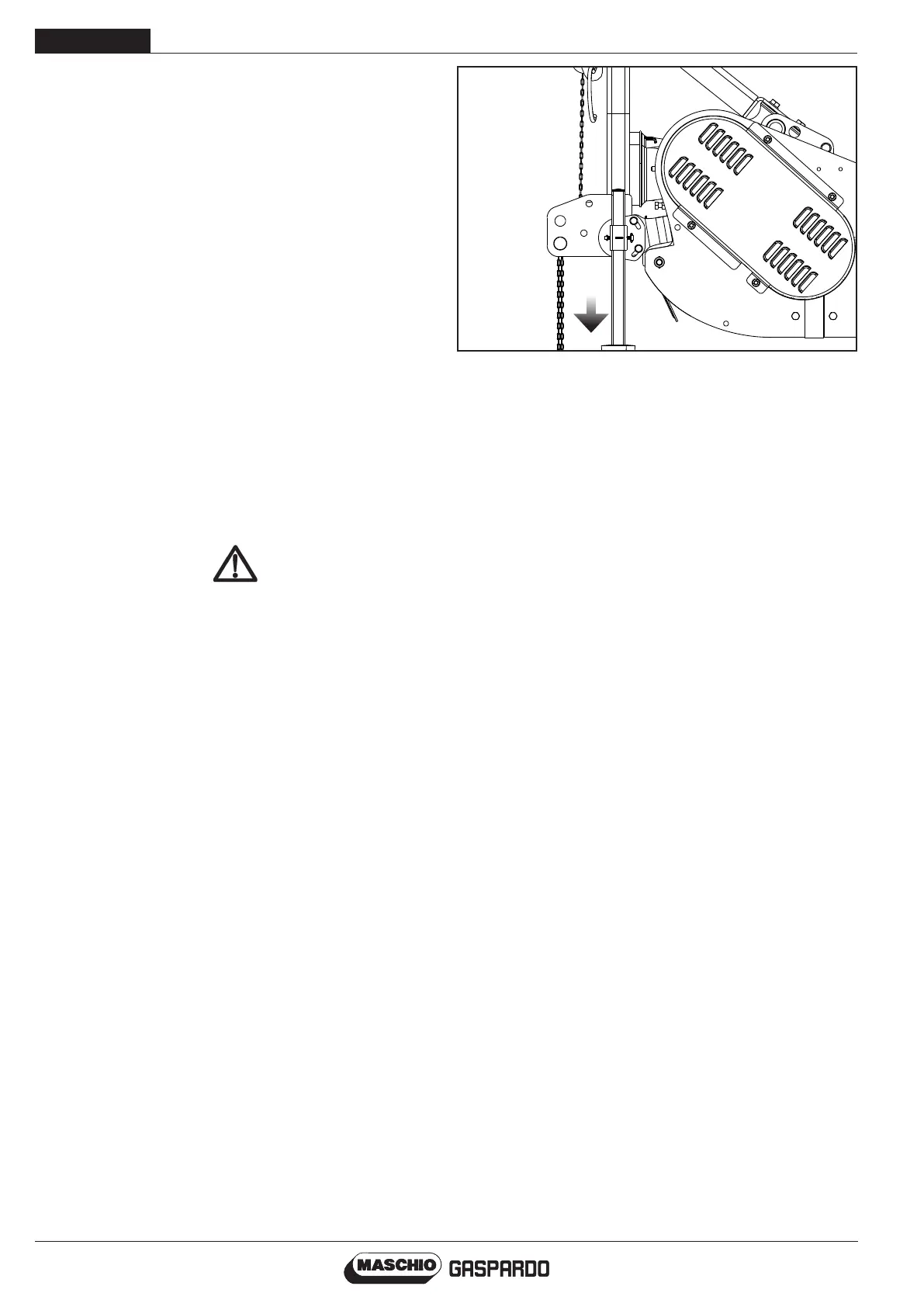

g.32

USE AND MAINTENANCE

ENGLISH

28

- Lower the machine to the ground.

- Make sure that machine is parked on a proper surface.

- Position the bearing stand as indicated in g.32 to

make the machine more stable.

5.0 MAINTENANCE

Here follows a list of various maintenance operations to

be carried out periodically. Lowered operating costs and

a longer lasting seeding machine depend, among others,

on the methodical and constant observation of mese rules.

The maintenance periods listed in this booklet are only

indicative and are for on normal conditions on use,

therefore be varied depending the kind of service, the

more or less dusty surroundings, seasonal factors, etc.

For more serious conditions of service, maintenance

will logically be done more often.

All operations must be carried out by expert personnel,

equipped with protective gloves, in a clean and dust-

free environment.

All maintenance operations must be carried out with the

machine hooked up to the tractor, the parking brake en-

gaged, the engine o, the ignition key removed and the

equipment sitting on suitable supports on the ground.

ATTENTION

USING OILS AND GREASES

- Before injecting grease, the nipples must be cleaned

to avoid mud, dustand foreign bodies from mixing with

the grease, otherwise they will reduce or even annul

the eect of the lubrication.

- Always keep oils and grease out of reach of children.

- Always read warnings and precautions indicated on

the containers carefully.

- Avoid skin-contact.

- After use wash the equipment thoroughly.

- Treat the used oils and polluting liquids in conformity

with the laws in force.

RECOMMENDED LUBRICANTS

- For lubrication in general, we advise: OIL SAE 80W/90.

- For all greasing points we advise: AGIP GR MU EP 2 GRE-

ASE or equivalent (specications: DIN 51825 (KP2K)).

CLEANING

- The products used for cleaning must be disposed of

according to the laws in force.

- Clean and maintain the machine after putting any removed

guards back in position. Replace them with new ones, if

they are damaged.

- Clean the electrical components only with a dry cloth.

USING PRESSURISED CLEANING SYSTEMS (Air/Water)

- Always keep in mind the rules that regulate use of

these systems.

- Do not pressure clean electrical components.

- Do not pressure clean chromium-plated components.

- Do not place the nozzle in contact with the parts of the

equipment, especially the bearings. Keep it at a min.

distance of 30 cm from the surface to be cleaned.

- Thoroughly lubricate the equipment, especially after clea-

ning it with pressurised systems.

HYDRAULIC SYSTEMS

- Hydraulic systems must be maintained exclusively by

skilled operators.

- The hydraulic system is under high pressure; because

of the accident risk, when searching for leakage points

special auxiliary instruments should be used.

- In case of participation on the hydraulic system, to un-

load the hydraulic pressure carrying all the hydraulic

commandos in all the positions some times after to

have extinguished the motor.

- Oil escaping at high pressure can cause skin injury

with the risk of serious wounds and infection. Call a

doctor immediately if such an incident occurs. If the oil

with surgical means is not removed quickly, can take

place serious allergies and/or infections. Therefore,

the installation of hydraulic components in the tractor

driver’s cab is strictly forbidden. All the components of

the system should be positioned carefully to avoid parts

being damage during use of the equipment.

- At least once a year have the hydraulic pipes checked for

wear by an expert.

- Replace the hydraulic pipes if they are damaged or worn

by aging.

- Replace the hydraulic pipes every 5 years even if they

have not been used (natural aging).

g.33 (R) shows hydraulic pipes bearing the year of ma-

nufacture as an example.

After the rst 10 hours of operation and then after every

50 hours, check that:

- all the elements of the hydraulic system are water-tight;

- all the joints are tight;

Before starting the machine up, check that:

- the hydraulic pipes are connected correctly;

- the pipes are positioned correctly, and they are free to

move during standard manoeuvres;

- any damaged or worn part is replaced, if necessary.

Replace the hydraulic pipes in the following cases:

- when external damage is identied such as cutting, tearing

and wear due to friction, etc.;

Loading...

Loading...