NomoLine ISA Service Manual Chapter 2: Maintenance Procedures

www.masimo.com 25 Masimo

Item

Description Item Description

2 Leave

disconnected

4 Connect to the ISA Input Connector.*

* See NomoLine ISA CO2/AX+ Interface on page 11 or ISA OR+ Interface on page 12.

Procedure

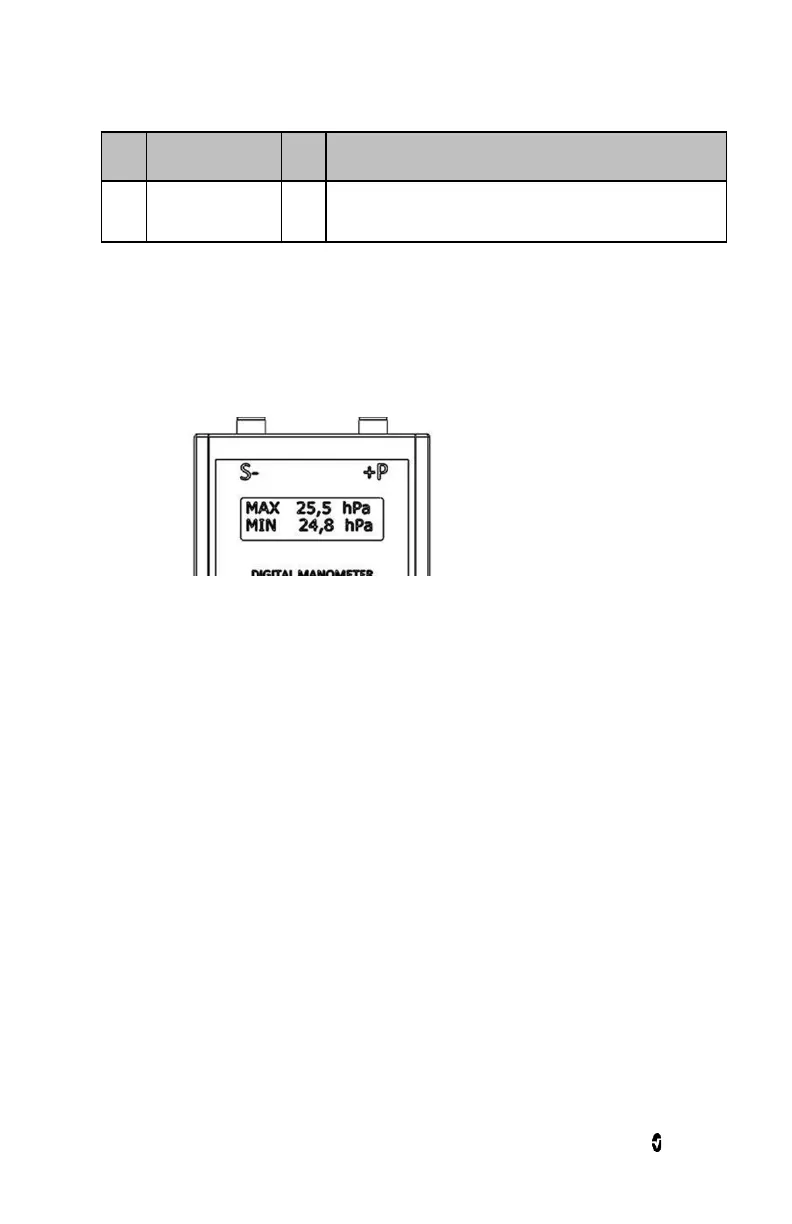

1. Configure the HM28 device to display measurement values in hPa.

2. Press "MODE" button until the display shows MAX/MIN values as in figure 1-13.

Figure 1-13

3. Make sure the NomoLine ISA system is powered ON.

4. Connect the NomoLine ISA Maintenance Kit to the NomoLine ISA Input Connector

shown in figure 1-12 and leave the exhaust open. See NomoLine ISA CO2/AX+

Interface on page 11 or ISA OR+ Interface on page 12.

Note: Verify the 4-way stopcock lever position in figure 1-12.

5. Press "CLEAR/ZERO" button on the HM28 digital manometer.

6. Wait for 30 seconds.

7. Calculate a mean value based on the MAX/MIN values displayed on the HM28

digital manometer.

Test result:

The NomoLine ISA system sampling flow rate

1

is inside specified range if the mean value is

within specified acceptance criteria

2

. The NomoLine ISA system should not be used if it fails

to meet the acceptance criteria limits.

1

Sampling flow rate: 50± 10 sml/min

2

Acceptance criteria: 16 to 24 hPa

Gas Span Check

Overview

The gas span check procedure requires the use of a suitable calibration gas mixture. A

cylinder containing such mixture may be acquired from the vendor of your choice, provided

the following gas concentrations and accuracy are met.

Loading...

Loading...