194

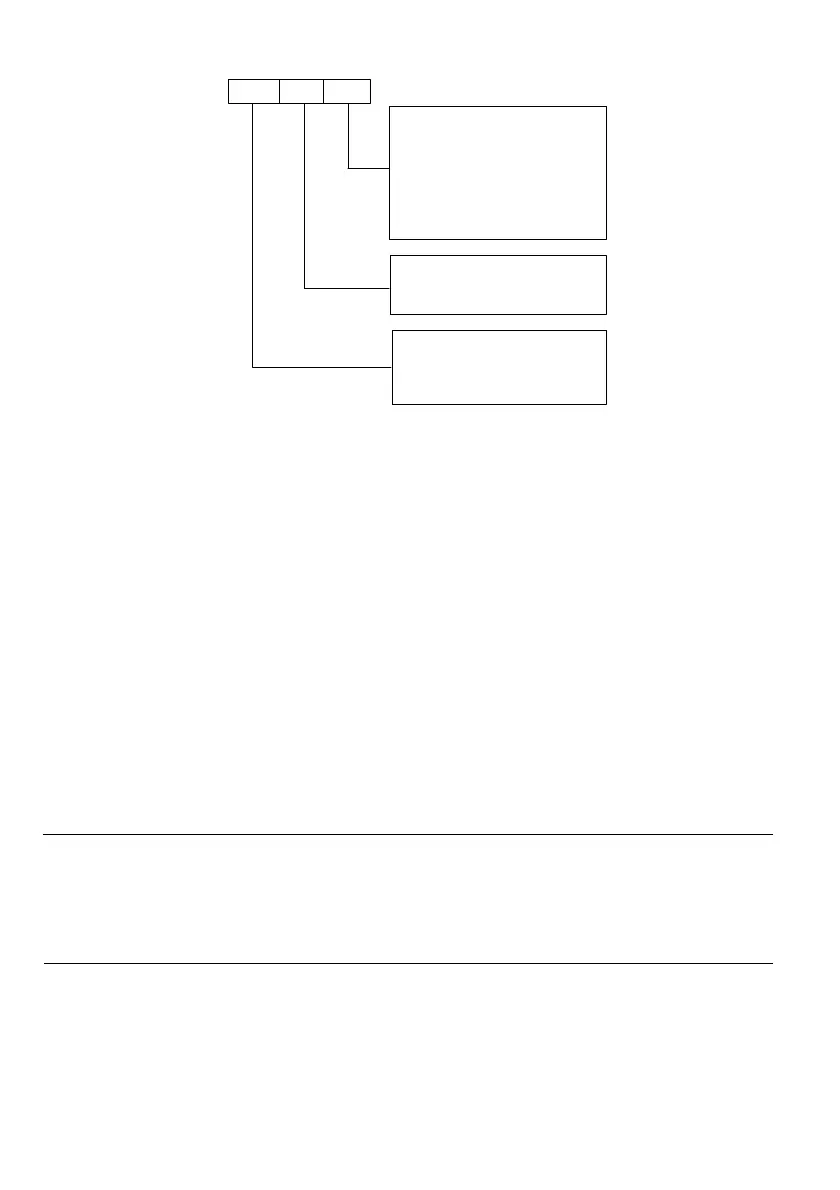

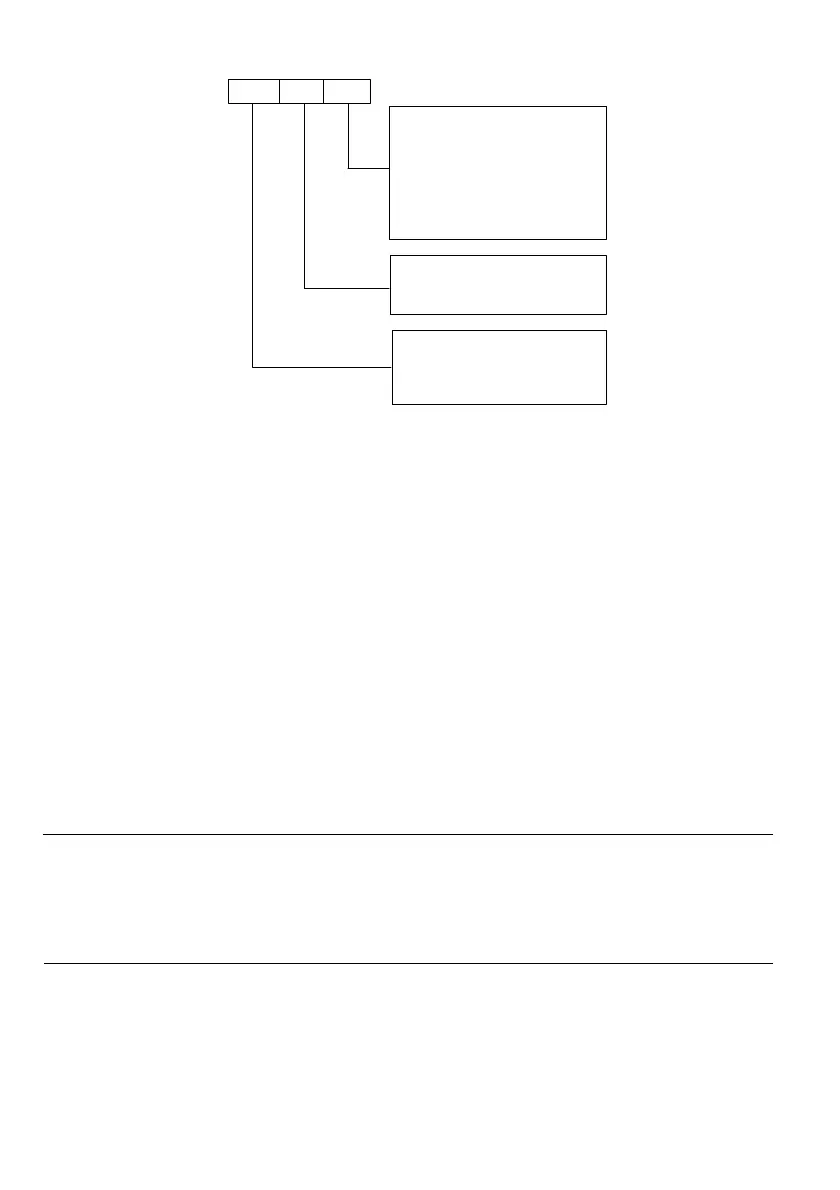

UnitTensHundreds

Frequency setting:

0: Select the multi-stage frequency

1: Keyboard reference

2: Terminal UP/DOWN reference

3: Reserved

4: AI reference

5: Reserved

6: PID

7: Reserved

Running direction setting:

0:FWD

1:

REV

2:Determined by running command

0: Acceleration/deceleration time1

Acceleration/deceleration time setting

1: Acceleration/deceleration time2

2: Acceleration/deceleration time3

3: Acceleration/deceleration time4

∨∧

Fig. 6-66 Setting of PLC stage

Unit place of LED setting of the PLC i stage:

0: Select the multi-stage frequency i

For example, when i=3, the frequency of stage 3 is the multi-stage frequency 3. For the definition of the

multi-stage frequency, please refer to P13.00~P13.46.

1: Digital reference 1: Keyboard ∧∨ reference

2: Digital reference 2: Terminal UP/DN reference

3: Reserved

4: AI analog reference

The function code P10.01 shall be set for AI analog reference. 1 or 9 shall be set for this terminal function

according to input analog signal (Their directions are all determined by LED’s tens place setting of PLC

current stage).

5: Reserved

6: Process closed loop PID

7: Reserved

Note

When the stage running direction of PLC is determined by running command, the running direction of motor

can be changed from external direction command in real time. For example, the forward and reverse running

can be realized via X terminal. The running direction is the direction determined by the running command; if

the direction is uncertain, then follow the direction of last section.

6.14 Process PID parameters (Group P14)

The PID closed loop control adopts the combinations of proportional control (P), integral control (I) and

differential control (D). This is a control mode which makes the feedback value consistent with the target

value.

Loading...

Loading...