204

In the stop parameter display state, the parameters for display can be switched in turn by pressing the

shift key 》.

This function code is used for correcting the line speed proportion display error, and it has no influence on

the actual rotating speed.

This function code is used for correcting the rotating speed proportion display error, and it has no influence

on the actual rotating speed.

This function code is used for correcting the display error between the actual physical parameters

(pressure, flow, etc.) and the reference or feedback parameter (voltage, current) in the PID closed loop

control, and it has no influence on the PID closed loop adjustment.

P16.06 indicates the temperature of the inverter module. The over-temperature protection values of the

inverter modules of different types may be different.

P16.07 indicates the temperature of the rectifier. The temperature of the rectifier bridge below

15kWG(18.5kWP)will not be detected.

Temperature display range: 0~150

℃; precision: 5%.

This function code indicates the motor temperature measured in actual situation.

P16.09~P16.11 are used for indicating the accumulated power-up hours, running hours and running

hours of the fan of the drive from leaving the factory to now.

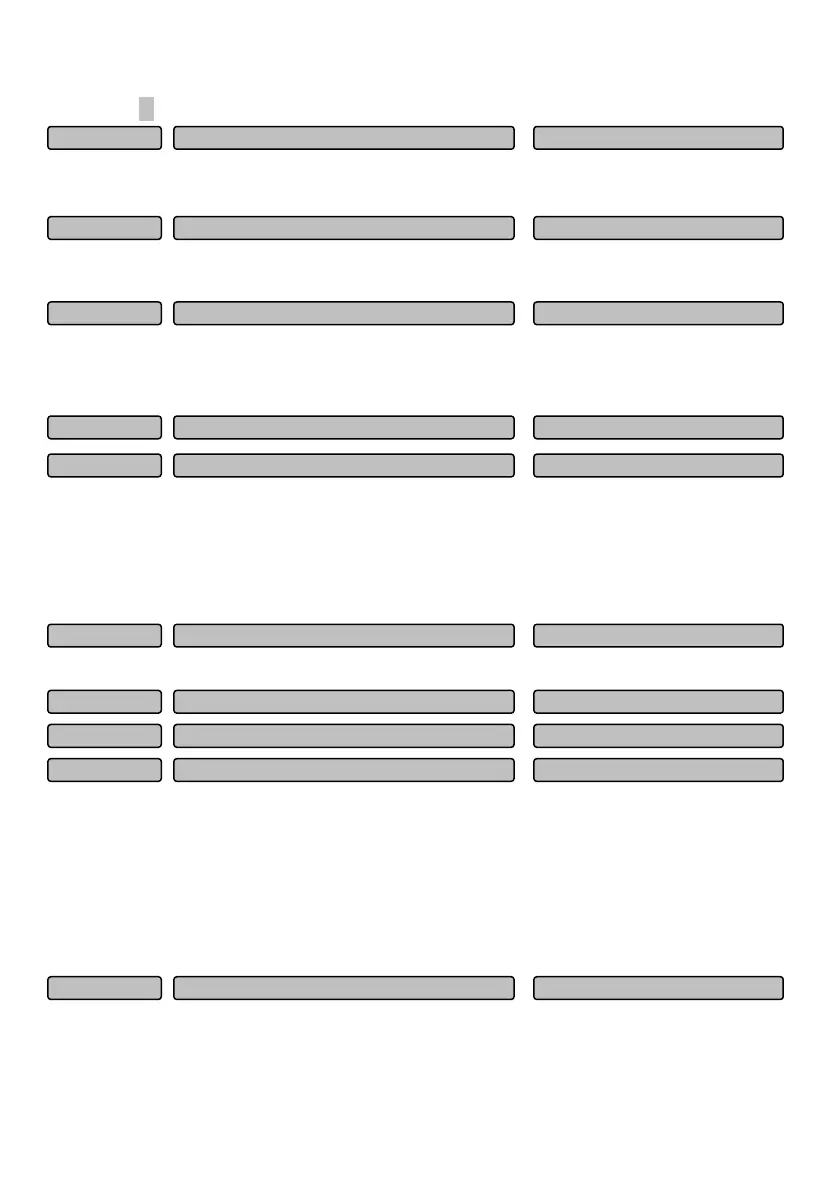

6.17 Fieldbus option parameters (Group P40)

The field bus option parameter group is used for indicating and setting parameters for the bus options.

This group of function codes is displayed only when the bus option works normally.

000: No communication option

001: Profibus-DP

Others: Reserved

O

tion t

e 000~FFF

000

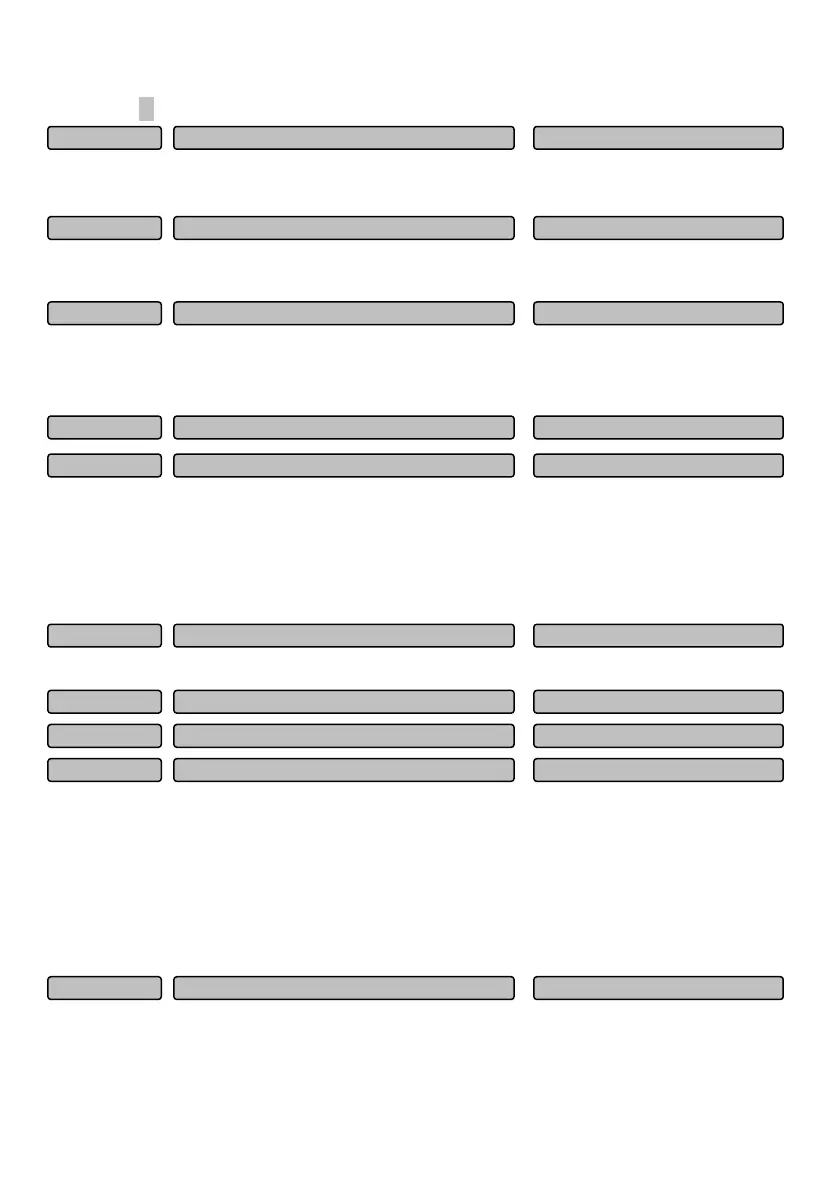

P40.00

Accumulated runnin

hours of fa

0~65535

0

P16.11

Accumulated runnin

time 0~65535

0

P16.10

Accumulated

owe

-on hours 0~65535

0

P16.09

Motor tem

erature measured

0~200℃

0

P16.08

Rectifier module tem

erature

0.0~150.0℃

0.0

P16.07

Inverte

module tem

erature

0.0~150.0℃

0.0

P16.06

Close loo

dis

la

coefficien

0.1~999.9%

100.0%

P16.05

Rotatin

s

eed dis

la

coefficien

0.1~999.9%

100.0%

P16.04

Line s

eed coefficien

0.1~999.9%

1.0%

P16.03

Loading...

Loading...