FOCKE MELER GLUING SOLUTIONS

5-2

MAINTENANCE

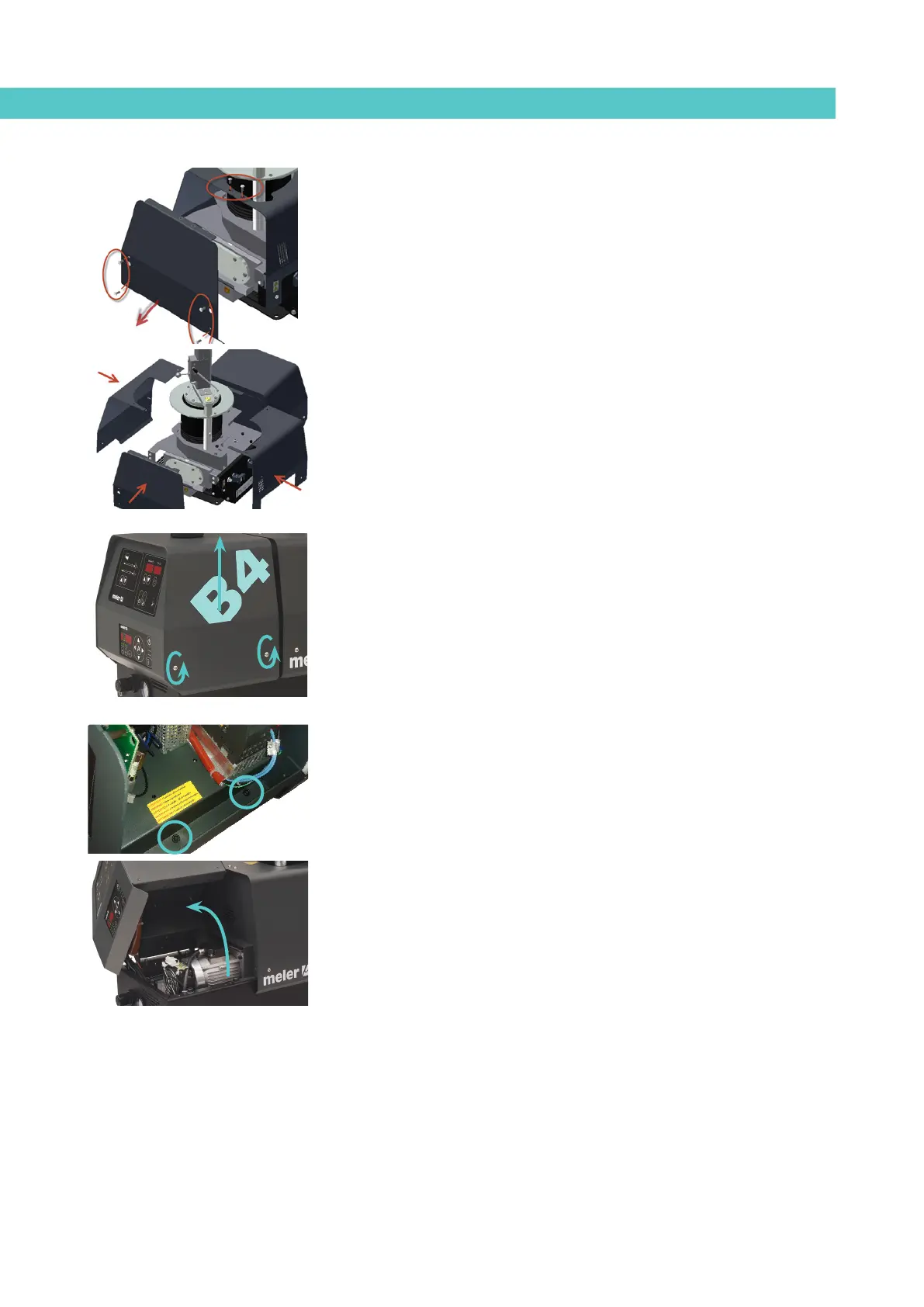

Removing the rear covers from the melter cylinder:

1. Disconnect the melter using the circuit breaker.

2. Remove the six screws fastening the cover to the melter unit.

3. Remove the cover, sliding it outwards in the direction shown in the

figure.

4. Remove the screws at the front and on the top of the side covers.

5. To reposition the covers, follow steps 1 to 4 in reverse order.

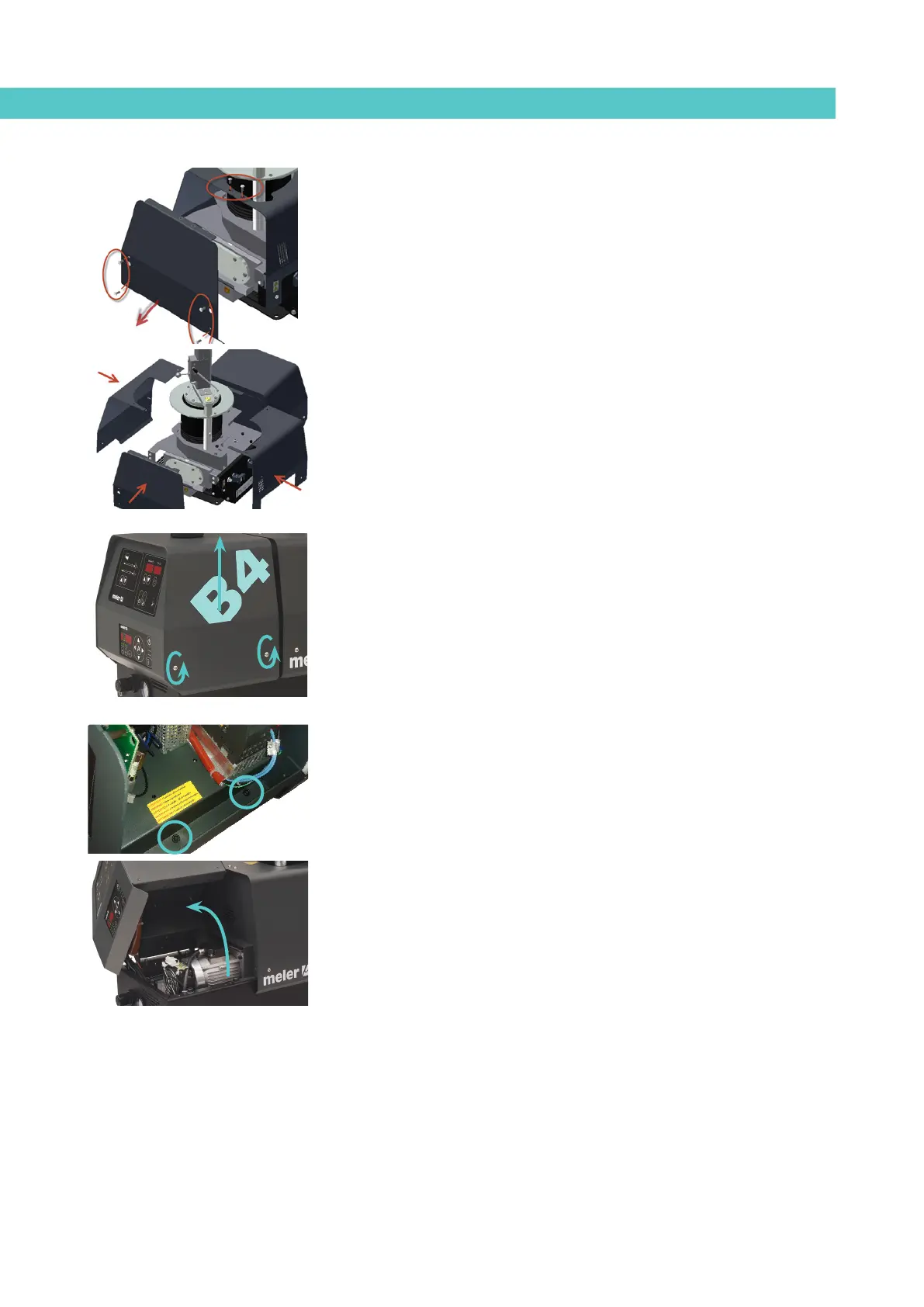

Removing the control box cover:

1. Disconnect the melter using the circuit breaker.

2. Remove the four screws fastening the cover to the equipment’s control

box.

3. Remove the cover, sliding it upwards in the direction shown in the

figure.

4. To replace the cover follow steps 1 to 3 in reverse order.

Opening the control box to access the components inside:

1. Perform steps 1 to 3 to remove the control box cover.

2. Remove the two screws fastening the control panel to the frame of the

melter.

3. Tilt the control panel to the left.

4. Follow steps 1 to 3 in reverse order to close the control panel.

System depressurisation

The B4 NS melter is a pressurised application system with the corresponding

risks that such a system entails. This equipment includes a safety valve

(bypass valve) which limits the maximum pressure in the system, particularly

during continuous pumping with closed application applicators.

However, in this last case, even with the motor stopped, residual pressure may

remain in the circuit. This should be taken into account when carrying out any

work on the hydraulic circuit.

Loading...

Loading...