Section 5 - Maintenance

90-864197076 NOVEMBER 2008 Page 91

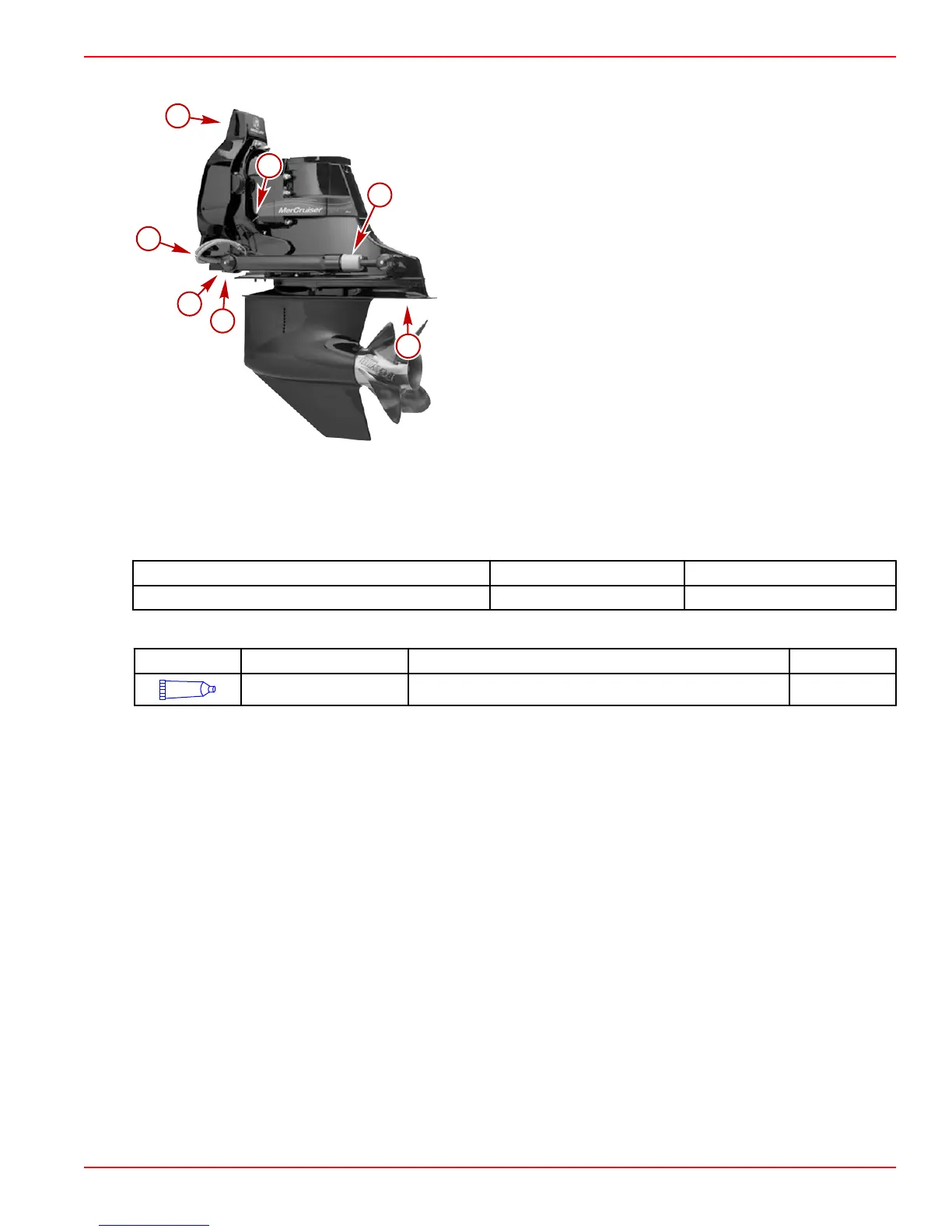

Sterndrive Surface Care

Standard Bravo sterndrive

a - Sacrificial trim cylinder anode

b - Sacrificial anodic plate

c - Steering lever ground wire

d - Ground wire between the gimbal ring and bell housing

e - Stainless steel hoses

f - Ground wire between the gimbal housing and trim cylinder

g - Ground wire between the gimbal ring and gimbal housing

We recommend the following maintenance items to help keep your sterndrive corrosion‑free:

• Maintain a complete paint covering on the sterndrive.

• Check the finish regularly. Prime and paint nicks and scratches using Mercury enamel paint and touch up paint. Use only tin–

based anti–fouling paint or its equivalent on or near aluminum surfaces below the waterline.

• If bare metal is showing, apply 2 coats paint.

Description Where used Part number

Mercury Phantom Black Bare metal 92‑ 802878‑1

• Spray all electrical connections with sealant.

Tube Ref No. Description Where Used Part No.

25

Liquid Neoprene All electrical connections 92- 25711 3

• Inspect the sacrificial trim tab or anode plate if equipped, at regular intervals and replace it before it is half gone. If a stainless

steel propeller is installed, additional anodes or a MerCathode System will be required.

• Inspect the propeller shaft for fishing line, which can cause corrosion on a stainless steel shaft.

• Remove the propeller at least every 60 days and lubricate the propeller shaft.

• Do not use lubricants containing graphite on or near the aluminum in saltwater.

• Do not paint trim tabs or the mounting surface.

Flushing the Power Package (Alpha)

Your boat comes equipped with through the sterndrive water pickups. See Sterndrive Water Pickups (following) for the flushing

procedure. Consult your authorized Mercury MerCruiser dealer for further explanation.

IMPORTANT: Alpha engines with the sterndrive water inlet blocked off at the gimbal housing, and using a through the hull water

inlet, need a supply of cooling water available to both the sterndrive and to the engine during operation

Loading...

Loading...