POWERHEAD

Page 4A-42 90-855347R1 JANUARY 1999

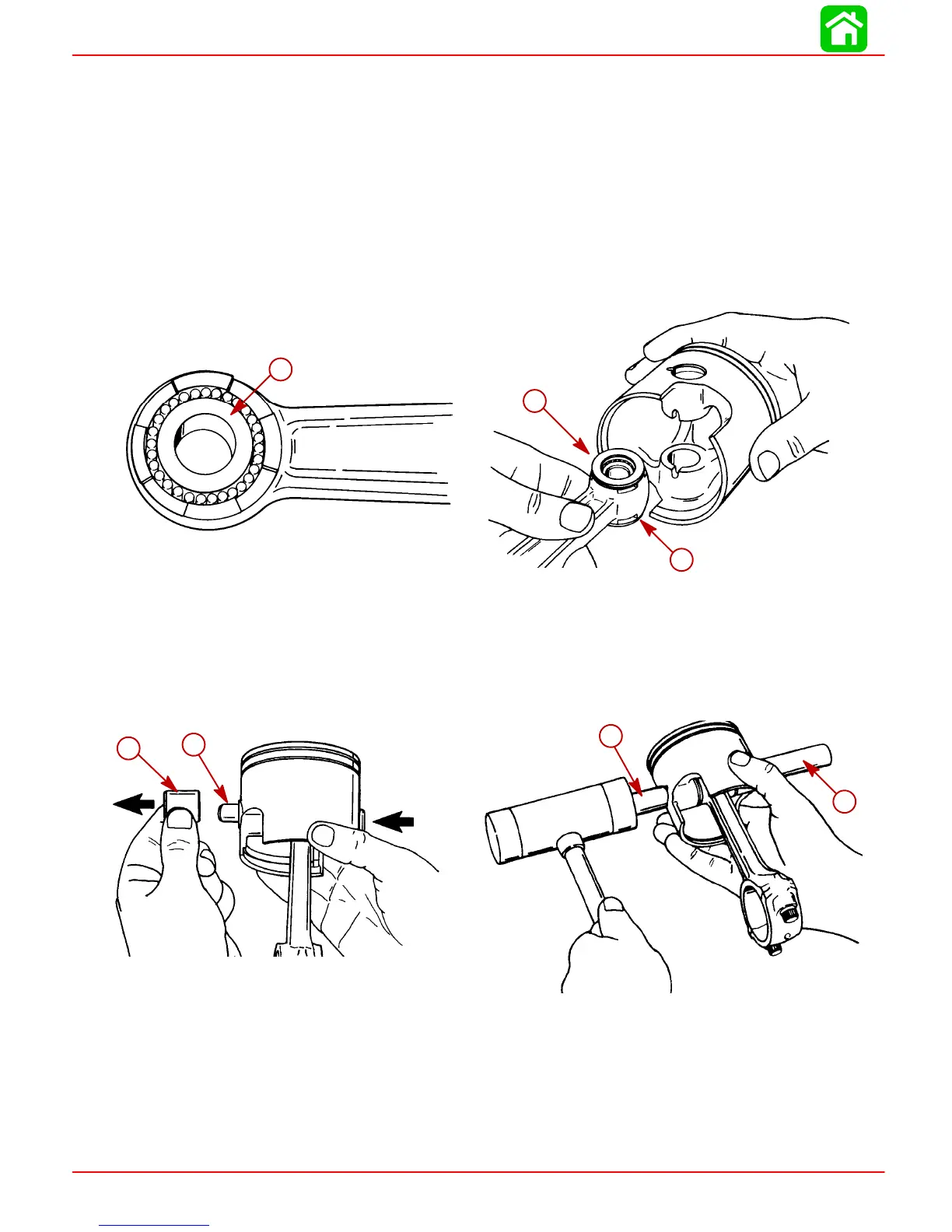

Piston and Connecting Rod Reassembly

1. Place needle bearings on a clean piece of paper and lubricate with Quicksilver 2-4-C

w/Teflon Marine Lubricant.

NOTE: There are 29 needle bearings per piston.

2. Place sleeve which is part of piston pin tool (91-74607A1) into connecting rod and in-

stall needle bearings around sleeve as shown.

3. Place locating washers on connecting rod.

IMPORTANT: Position connecting rod part number facing towards flywheel.

Carefully position piston over end of rod. Make sure locating washers remain in place.

51851

b

51851

b

a

a-Sleeve (Part of Tool Assy. 91-74607A1)

b-Locating Washers

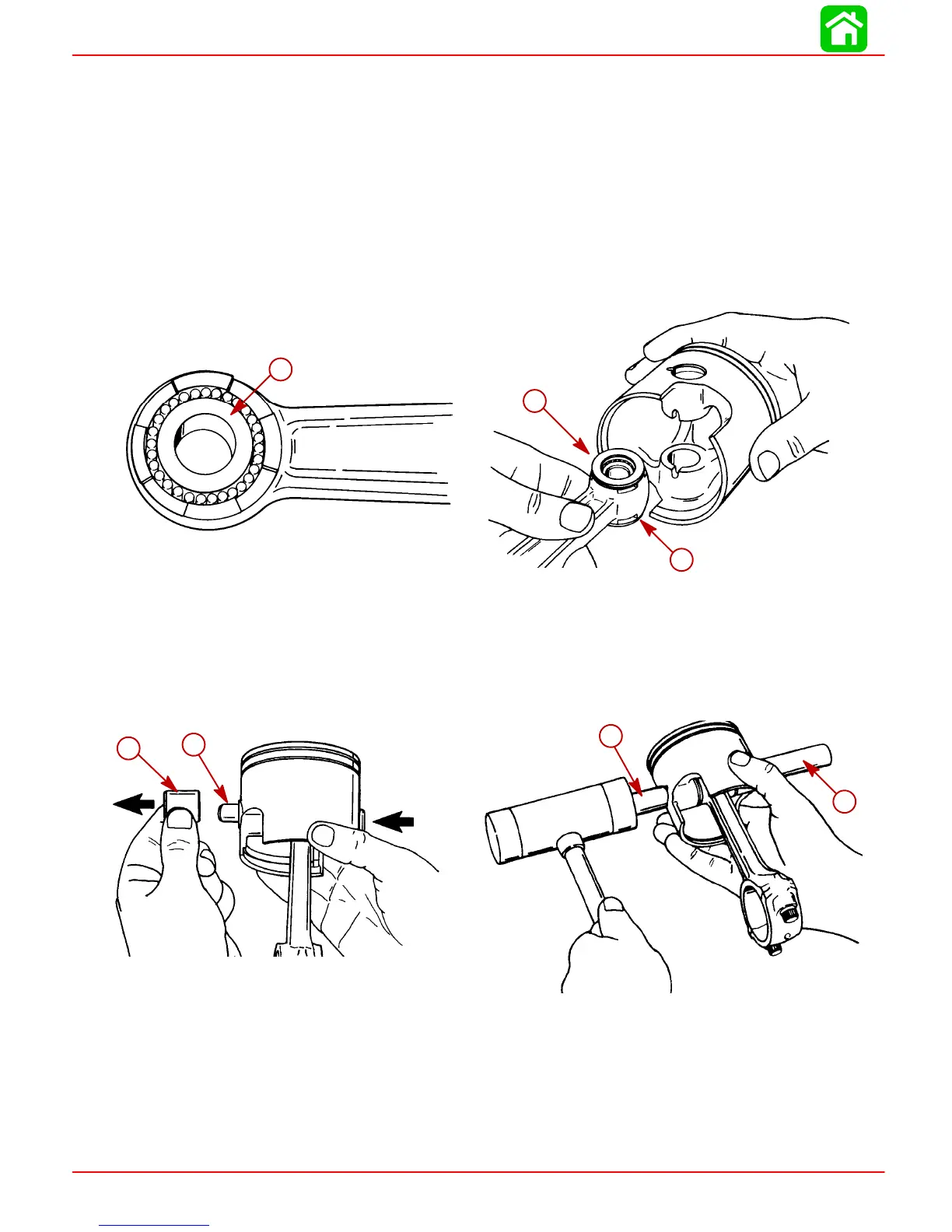

4. Insert piston pin tool (91-74607A1) and push sleeve out of piston. Keep piston pin tool

in piston.

5. Use a mallet and tap piston pin into piston and push piston pin tool out.

51086

51080

c

d

a

b

a-Piston Pin Tool (91-74607A1)

b-Sleeve

c-Piston Pin

d-Piston Pin Tool

Loading...

Loading...