POWER TRIM

Page 5B-40 90-855347R1 JANUARY 1999

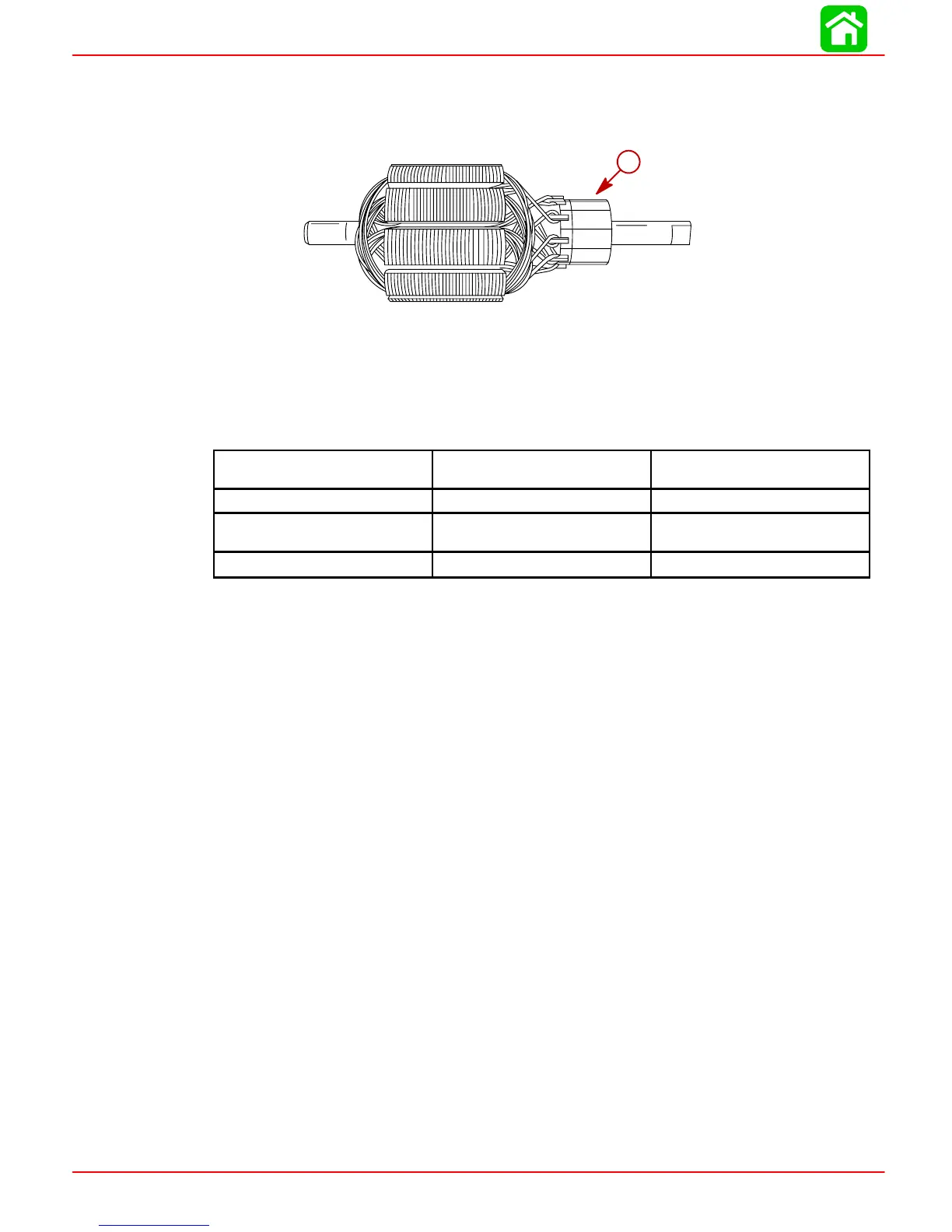

CHECKING AND CLEANING COMMUTATOR

1. If commutator is worn it may be turned on an armature conditioner or a lathe.

2. Clean commutator with “OO” sandpaper.

53775

a

a-Commutator

FIELD TESTS

IMPORTANT: Commutator end of armature must be installed in brushes when per-

forming the following tests.

Ohmmeter

Leads Between

Resistance

(Ohms)

Scale Reading*

(x____________)

BLUE and BLACK Motor Wires 0 (Rx1)

BLACK Motor Wire, and Frame

(Motor Housing)

No Continuity (Rx1)

BLUE Motor Wire and Frame No Continuity (Rx1)

*If specified readings are not obtained, check for:

• defective armature

• dirty or worn brushes

• dirty or worn commutator

If defective components are found, repair or replace component(s) and retest.

Motor Repair

REMOVAL

NOTE: Power Trim System does not have to be removed from outboard to repair/replace

motor.

DISASSEMBLY

Refer to “Motor Disassembly” on page 5B-38 to disassemble motor from pump.

Loading...

Loading...