RIGHT HAND NON-RATCHETING

90-855347R1 JANUARY 1999 Page 6A-33

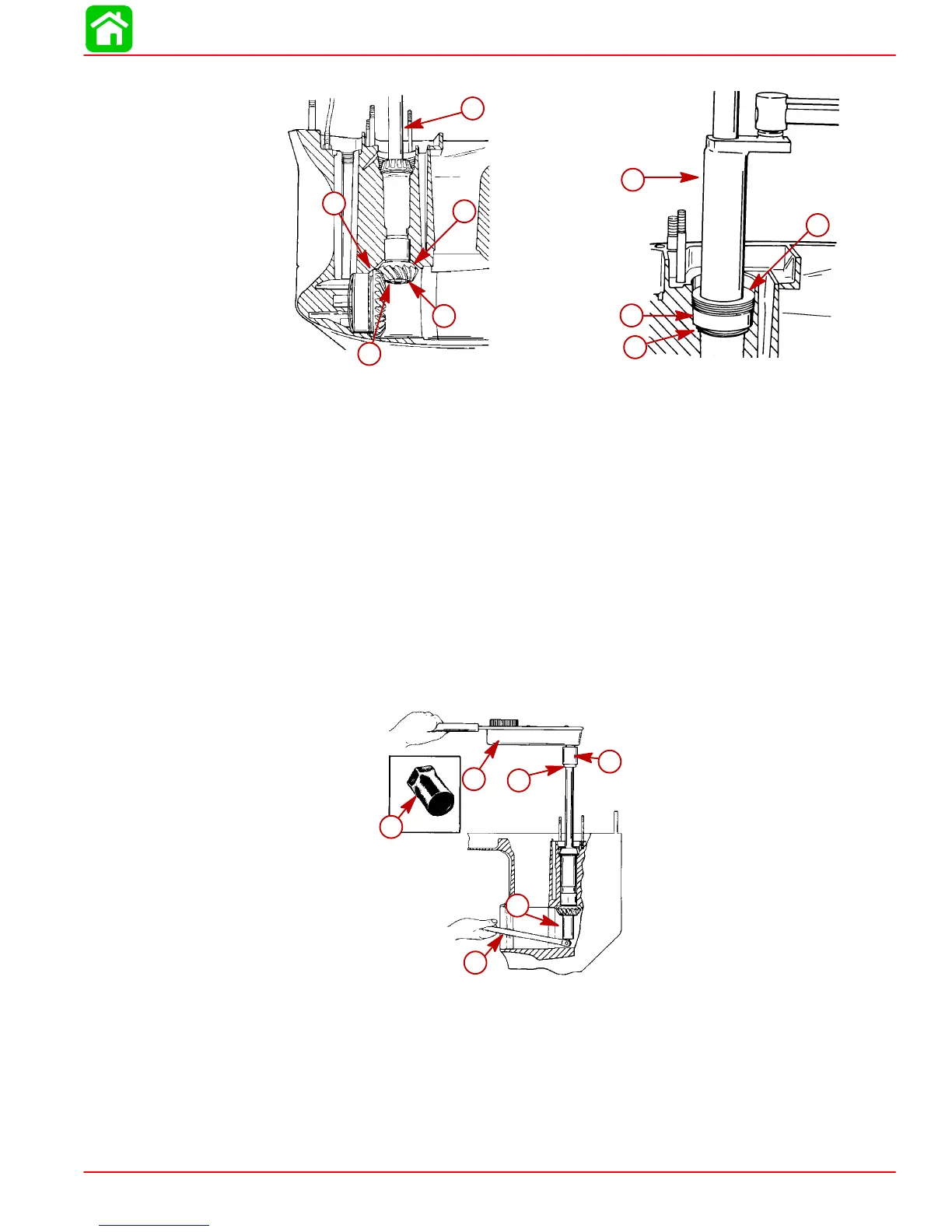

9. Install bearing race and bearing retainer.

51880

51867

f

g

h

i

a

b

c

d

e

a-Driveshaft (rotate to engage splines with pinion gear)

b-Forward Gear Assembly

c-Pinion Gear

d-Washer (located above pinion nut)

e-Pinion Nut (apply Loctite 271 on threads and install with flat side away from

pinion gear)

f-Shim(s)

g-Bearing Race

h-Bearing Retainer (Word “OFF” must be visible) Torque to 100 lb. ft.

(135.5 Nm)

i-Bearing Retainer Tool (91-43506)

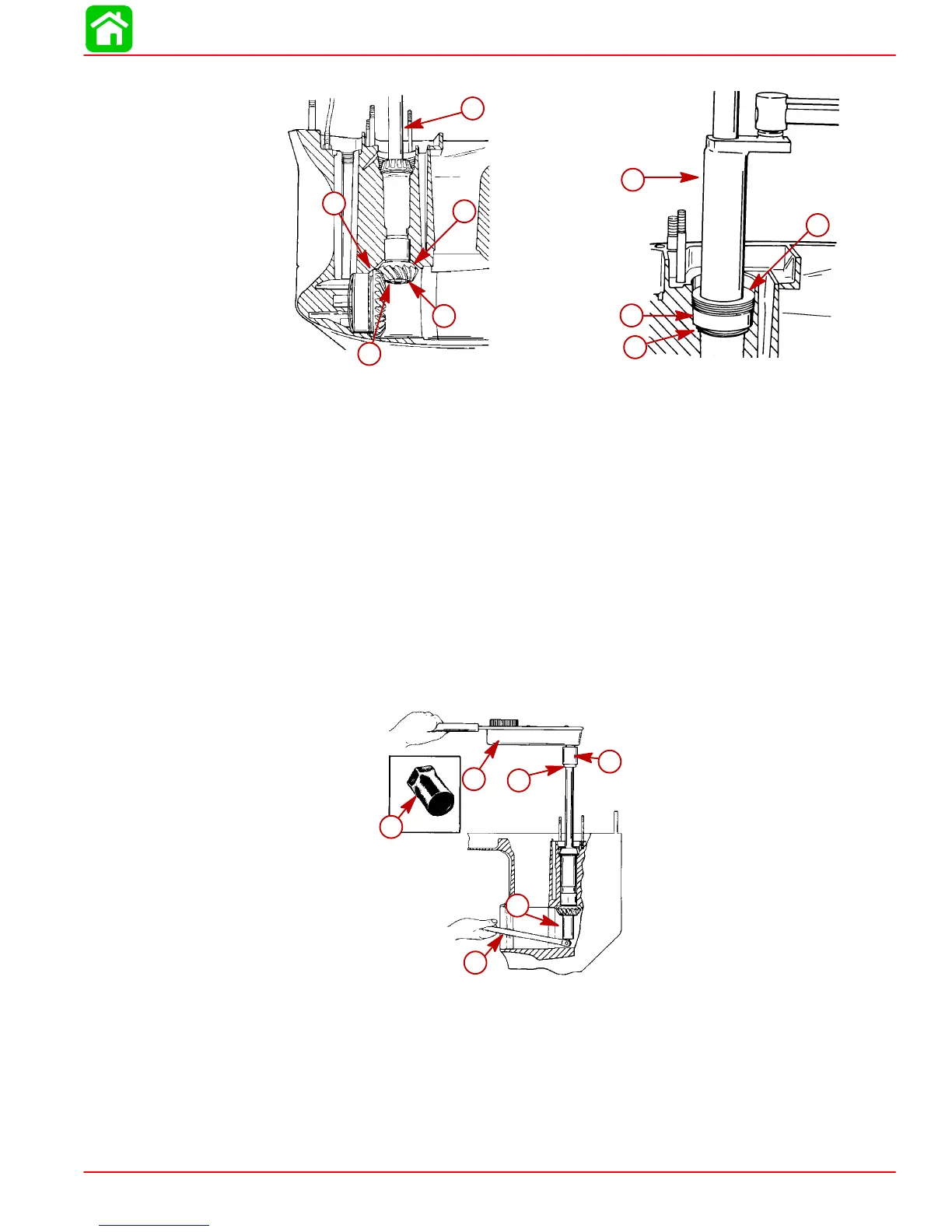

10. Use a socket and flex handle to hold pinion nut (pad area where flex handle will con-

tact gear housing while torquing nut).

11. Place Driveshaft Holding Tool (91-34377A1) or (91-90094) over crankshaft end of

driveshaft. Torque pinion nut to 75 lb. ft. (101.5 Nm).

a

b

a

c

c

d

a-Driveshaft Holding Tool (91-34377A1)

b-Torque Wrench; Torque Nut to 75 lb. ft. (101.5 Nm)

c-Socket

d-Breaker Bar

IMPORTANT: Wipe any excess Loctite from pinion nut and pinion gear.

Loading...

Loading...