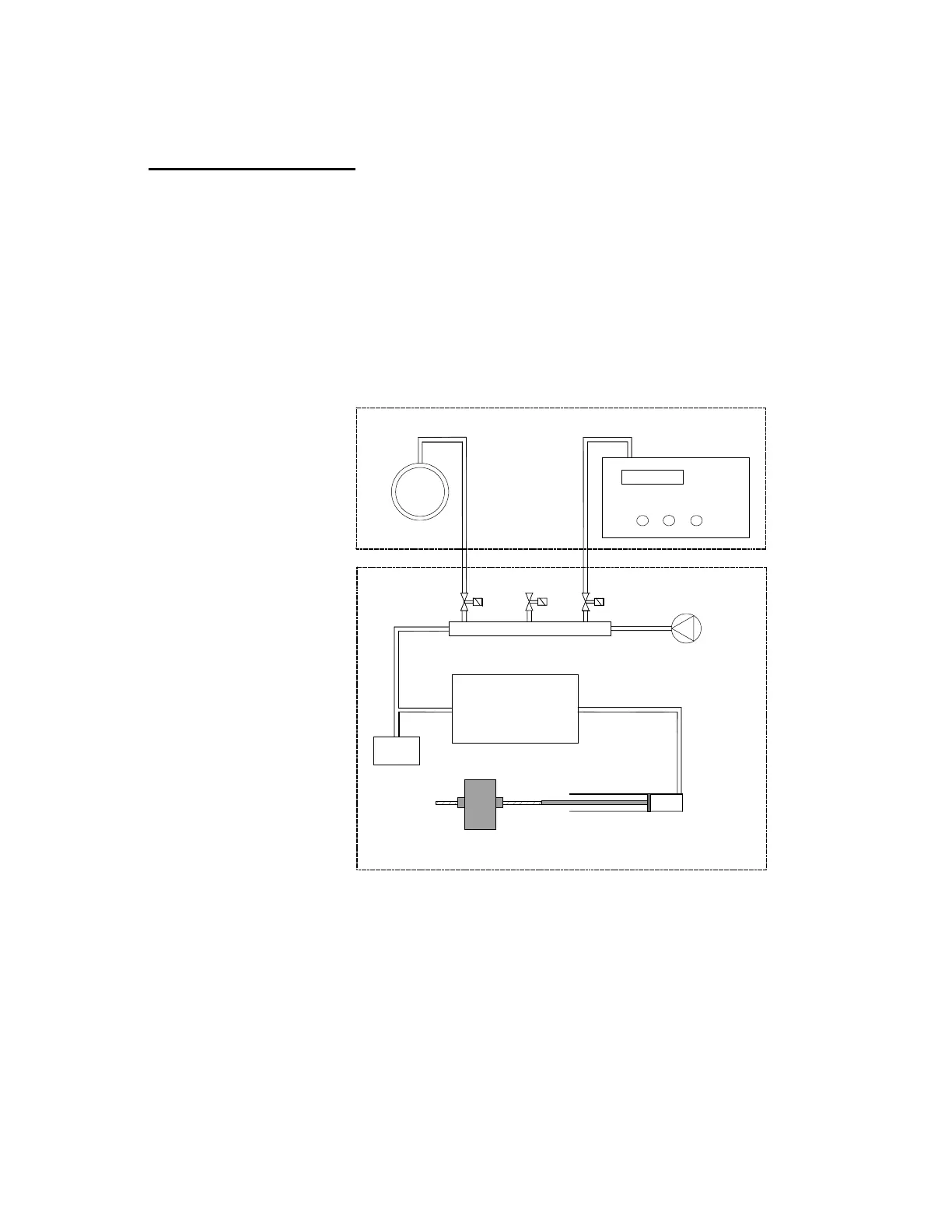

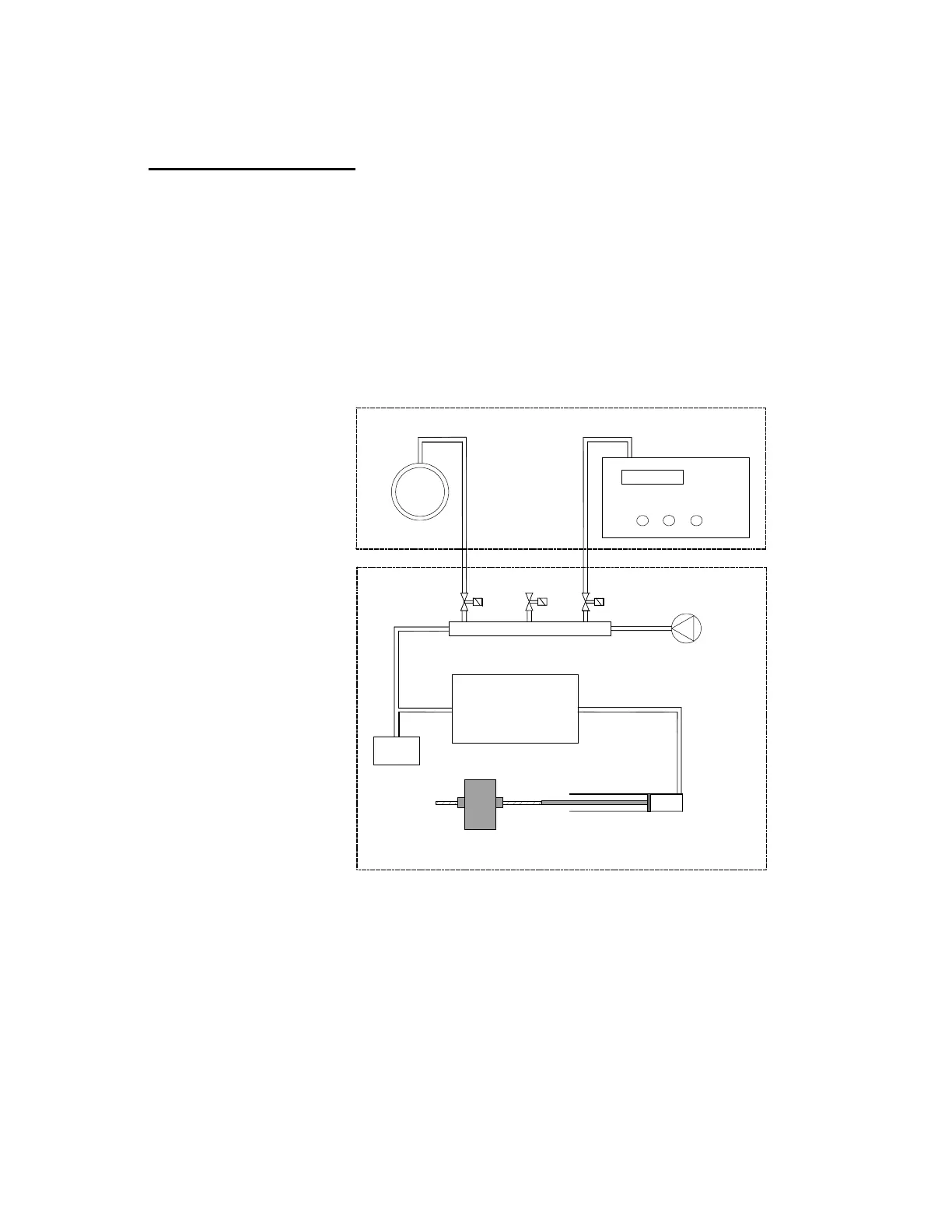

8.4 Pneumatic System

The pneumatics and drivers are the QA-1290’s mechanical parts that

deal with the air pressure and pulse generation, and their electrical

drivers. This involves the electrically operated air valves that control

airflow with the cylinder and piston. These are, in turn, controlled by

the stepper motor in order to generate pulses. The system is used for

generating blood pressure pulses and to set up pressure for leakage test

and over pressure test. The following diagram shows the QA-1290

pneumatic system’s functions.

Blood Pressure Monitor

Cuff

Internal "Cuff" (fixed volum)

Compressor

Valve Block

Pressure

Sensor

Ventilate

Valve

Cuff

Valve

Monitor

Valve

Step motor /

linear actuator

Pneumatic Cylinder

QA-1290

Device Under Test

QA-1290 Pneumatic System Drawing

A miniature compressor generates the pressure needed for the Leak and

Over-Pressure Cutoff Tests. It is also used during blood pressure simu-

lations for creating minor, rapid increases in pressure to simulate that

patient movement (i.e., when you press MOTION (F3)). Because the

compressor may have a little leakage that affects the leak test, a back

valve is inserted between the compressor and valve block.

The valve block has three valves to control the airflow. One connects

and disconnects the blood pressure monitors to the pneumatic system.

The second valve connects and disconnects the cuff to the pneumatic

8-5

Loading...

Loading...