14 1 X 78 en

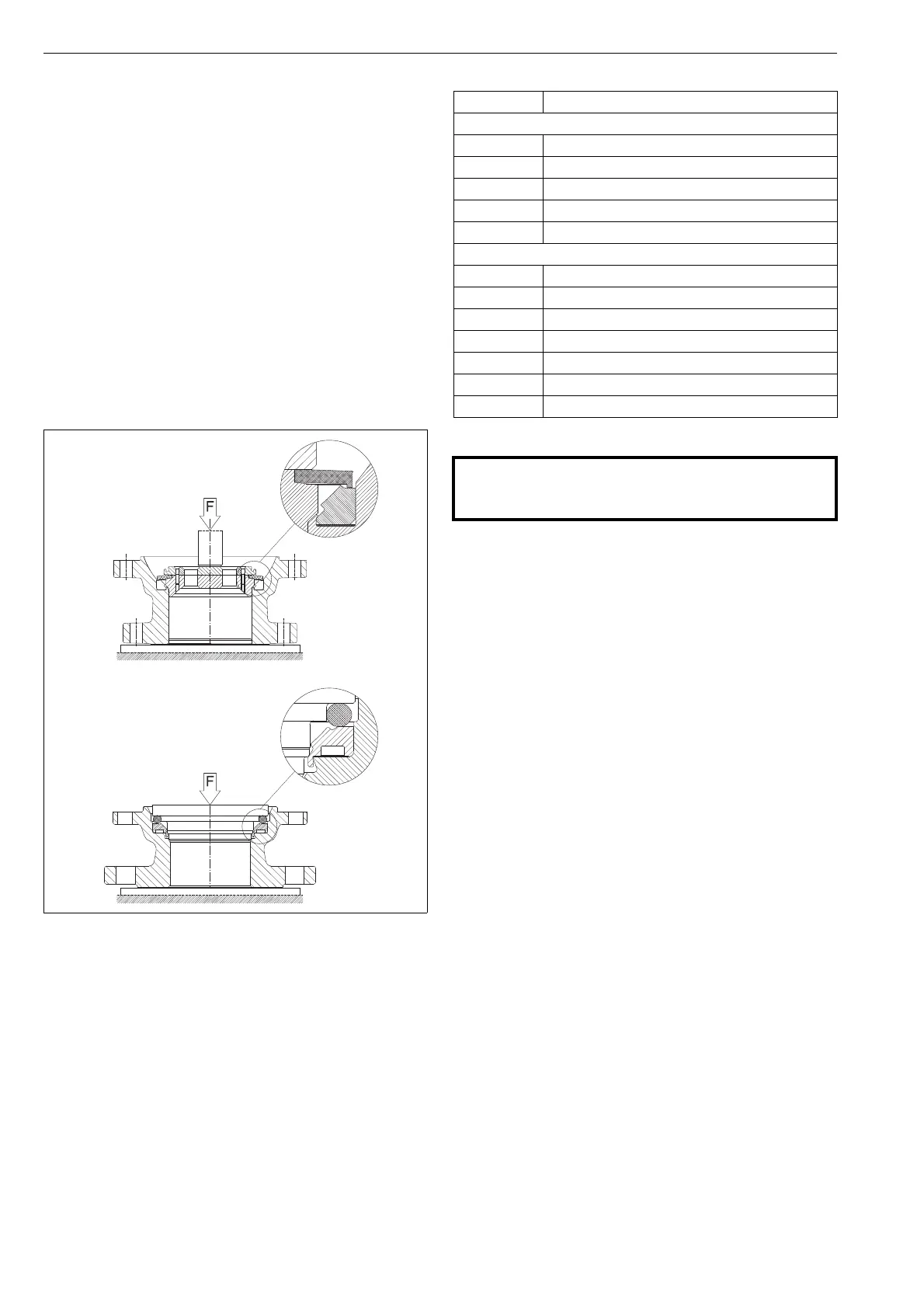

4.9.3 Locking of the seat

A seat locking tool (can be ordered from the manufacturer)

and a hydraulic press with suitable capacity are needed for

locking.

Mount the seat with the back seal as described in the

earlier section.

Mount the locking tool carefully over the seat, see

Fig. 33.

Place the valve body/body cap on the bed of the

press. The bed surface must be level and non-

scratching.

Align the valve and locking tool properly with the

piston of the press.

Press the tool to lock the seat. See Table 6 for press-

ing forces.

Remove the body/body cap from the press and con-

tinue the reassembly as described in the earlier sec-

tion.

5 TESTING THE VALVE

Test the valve’s body pressure after reassembly.

Test the pressure in accordance with an applicable standard. Use

the pressure required by the pressure class or the flange bore. Keep

the valve in the half open position during the test.

If the tightness of the closure member is also to be tested,

please contact the manufacturer.

If testing according to the UOP 671 specification is required,

follow appropriate instructions.

Fig. 33 Locking of the seat

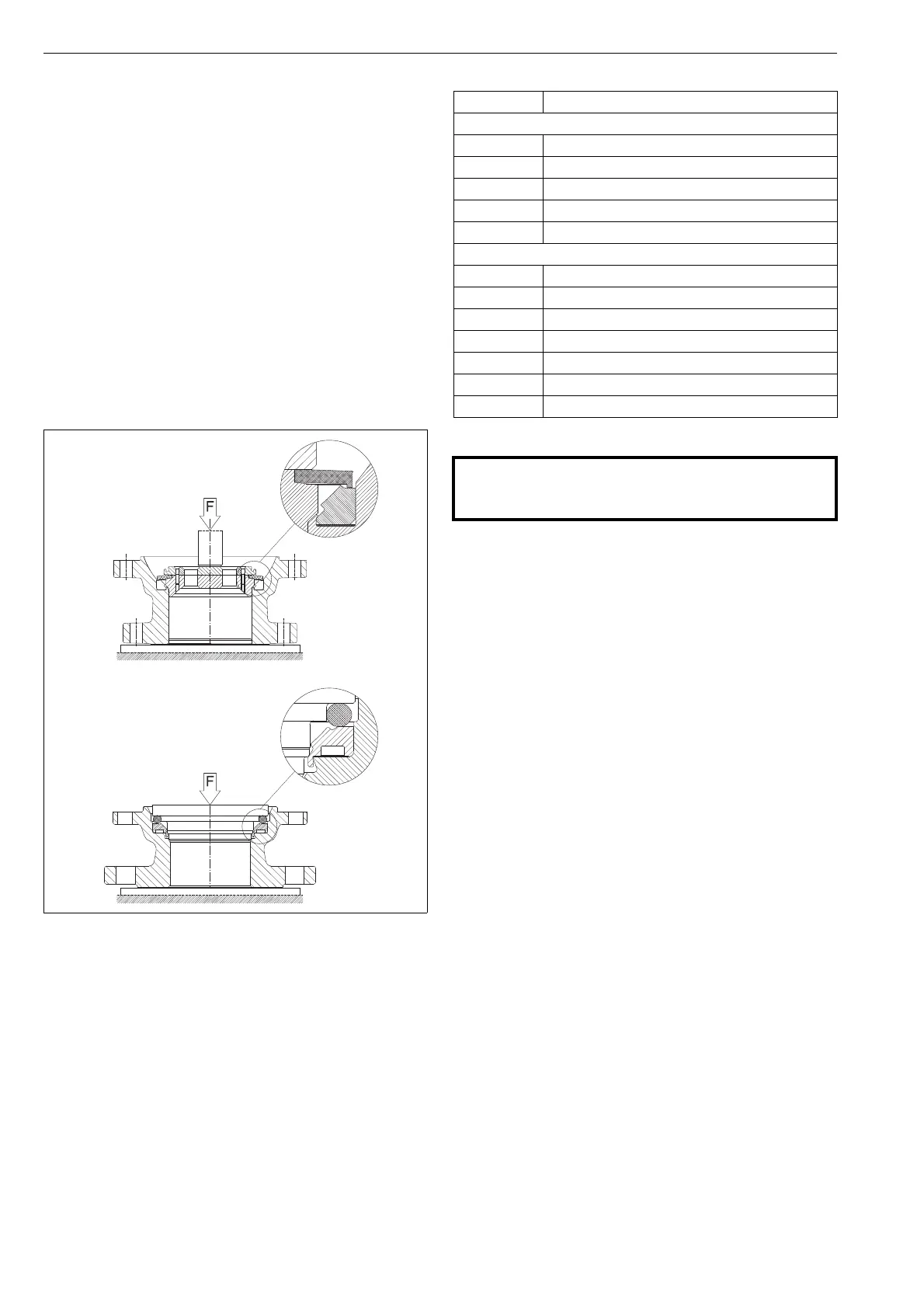

Table 6 Pressing forces for seat locking

Valve size Force (kN)

TA construction

02 70

03 140

04 160

06 250

08 370

GA construction

01 55

1H 75

02 130

03 110

04 125

06 200

08 400

CAUTION:

Pressure testing should be carried out using equipment

conforming to the correct pressure class!

Loading...

Loading...