22 1 X 78 en

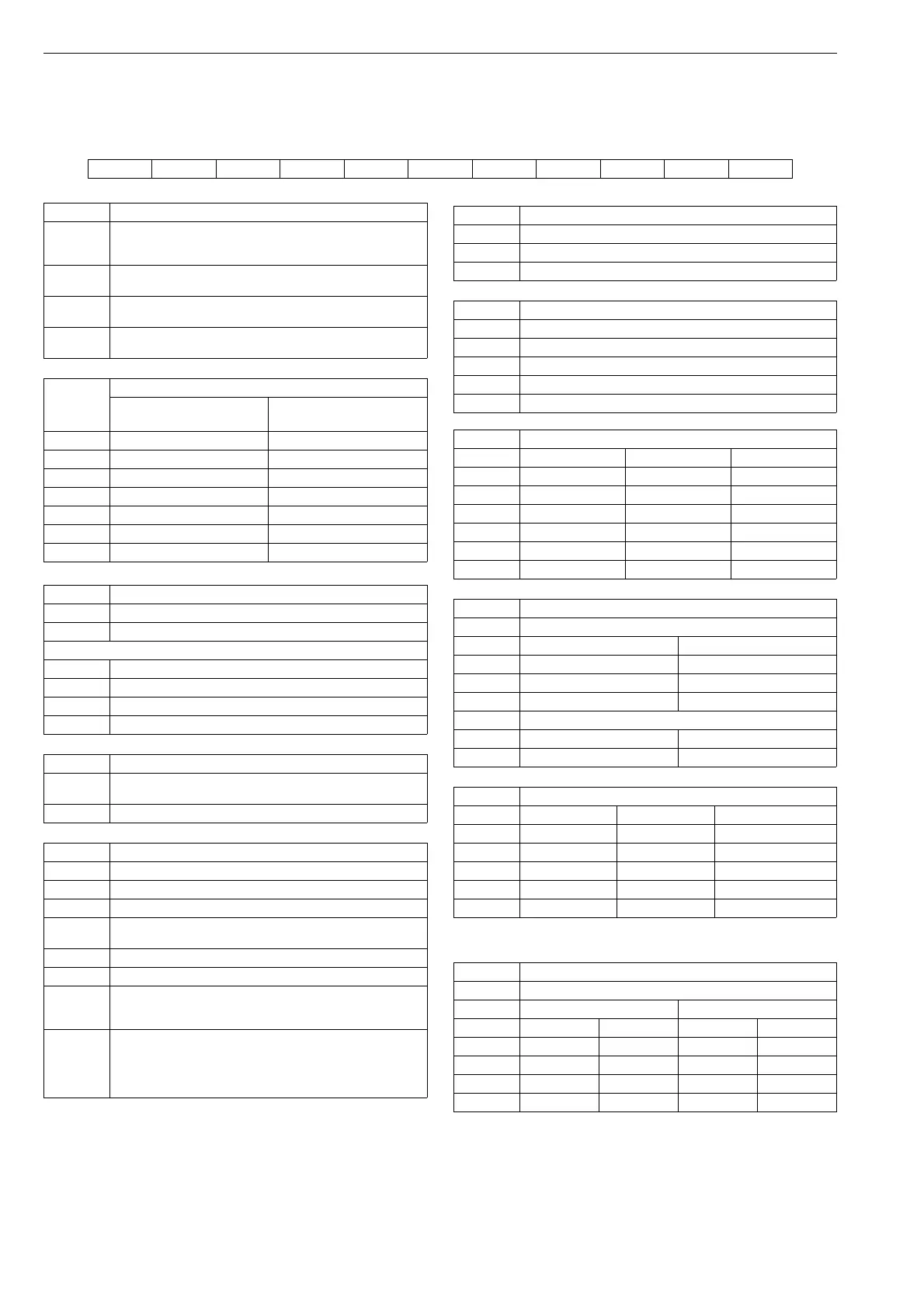

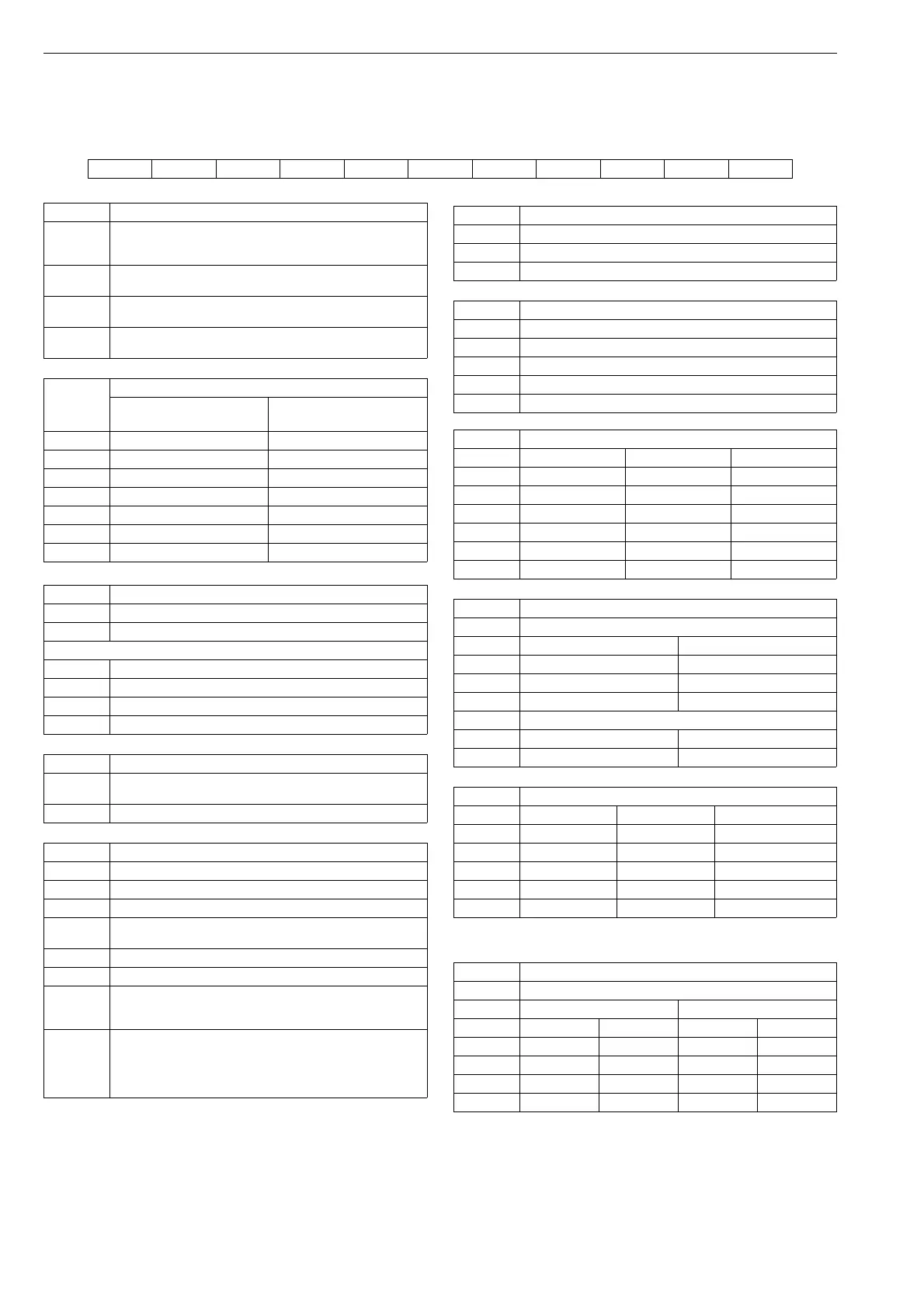

12 TYPE CODE

(* NACE compatible

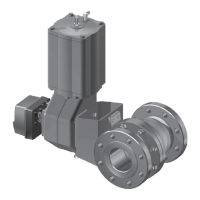

Modular ball valves, Series XA, XT, XB, XC, seat supported

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11.

XT 06 D W GA J2 SJ S A A F

1. sign VALVE SERIES AND STYLE AND FACE-TO-FACE

XT

Full bore, seat supported, face-to-face ASME B 16.10,

Table 1, long pattern, ASME 150

(1" acc. to EN 558-1 basic, series 4; 165 mm)

XA

Full bore, seat supported, face-to-face ASME B 16.10,

Table 2, long pattern, ASME 300.

XB

Reduced bore, seat supported, face-to-face ASME B 16.10,

Table 1, short pattern, ASME 150

XC

Reduced bore, seat supported, face-to-face ASME B 16.10,

Table 2, short pattern, ASME 300

2. sign

SIZE

Full bore

NPS / DN

Reduced bore

NPS / DN

01/025 1"/ 25 mm –

1H/040 1 1/2"/ 40 mm –

02/050 2" / 50 mm –

03/080 3" / 80 mm 3" / 80 mm

04/100 4" / 100 mm 4" / 100 mm

06/150 6" / 150 mm 6" / 150 mm

08/200 8" / 200 mm 8" / 200 mm

3. sign PRESSURE CLASS / ASME

C ASME Class 150 (XT)

D ASME Class 300 (XA)

PRESSURE CLASS / EN

J PN 10 (XT)

K PN 16 (XT)

L PN 25 (XA)

M PN 40 (XA)

4. sign END CONNECTION STYLE

W

Raised face, ASME B 16.5, “smooth finish” (Ra 3.2-6.3),

standard

C EN 1092-1 Type B1 (Ra 3.2 – 12.5).

5. sign CONSTRUCTION AND APPLICATION

GA Standard construction. Live loaded TA-Luft packing.

GQ Q-Trim construction. Otherwise standard.

UU UOP construction with solid proof J-seat

TU

Special solids proof seat design, pressure area 0...10 bar (

ambient)

TA Standard construction. Live loaded TA-Luft packing.

TQ Q-Trim construction. Otherwise standard

GZ

BAM tested non-metallic parts, for oxygen service. Double

seated. Metal bearings; cobalt based alloy. Live loaded

graphite packing. Temperature range -50...+200C

TZ

BAM tested non-metallic parts, for oxygen service. Double

seated. Metal bearings. Live loaded graphite packing.

Temperature range -50...+200C.

Oxygen cleaning acc. to Metso internal procedure T-2115

included.

6. sign BODY MATERIAL

J2 ASTM A216 gr WCB

S6 ASTM A351 gr CF8M

J5 ASTM A217 gr C5

7. sign BALL / COATING AND STEM MATERIAL

SJ 316 Stainless steel / Hard Chrome and XM-19 (Nitronic 50)

SP 316 Stainless steel and XM-19 (Nitronic 50) (soft seats only)

RX 316 Stainless steel / CrC and XM-19 (Nitronic 50)

RR 316 Stainless steel / WC-CO and XM-19 (Nitronic 50)

SL 316 Stainless steel / NiBO and XM-19 (Nitronic 50)

8. sign SEAT TYPES, BACK SEALS AND SPRING MATERIAL

Seat type Back seal type Spring

S Metal PTFE -

K Metal (locked) PTFE -

H Metal Graphite Incoloy 825

G Metal Graphite Incoloy 825

J Metal Graphite -

T Soft - -

9. sign SEAT AND COATING MATERIAL

Metal seated valves

Seat material Coating

A 316 Stainless steel Cobalt based hard facing

B 316 Stainless steel Chrome carbide, CrC-LF

R 316 Stainless steel Tungsten Carbide, WC-Co

Soft seated valves

Seat material Filler

X Xtreme -

10. sign BEARING AND SEAL MATERIALS

Body gasket Packing Thrust bearing

A SS316+PTFE PTFE V-rings Carbon Filled PTFE (*

B SS316+Graphite Graphite Carbon Filled PTFE (*

C SS316+PTFE PTFE V-rings Cobalt based alloy (*

D SS316+Graphite Graphite Cobalt based alloy (*

T SS316+Graphite PTFE V-rings Cobalt based alloy (*

11. sign BOLTING MATERIALS

Bolting material with unified thread

Pressure retaining Packing gland bolting

Studs Nuts Studs Nuts

E B8M 8 M gr. 660 gr. 660

T L7M 2HM B7 2H

S L7M 2HM gr. 660 gr. 660

A B7 2H B7 2H

Loading...

Loading...