1 X 78 en 9

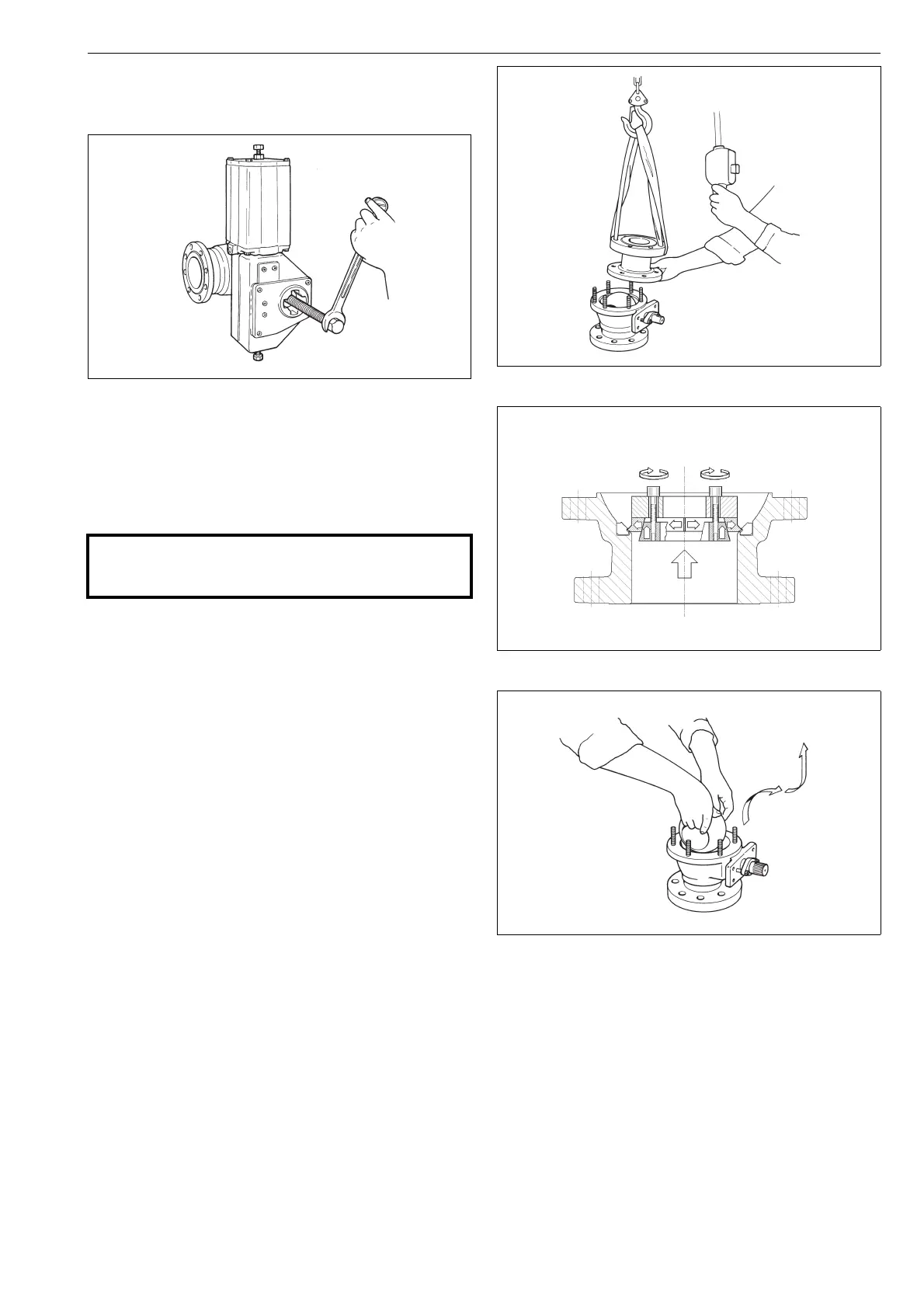

Close and detach the actuator pressure supply and

disconnect the control cables and pipes.

Loosen the bracket screws.

Detach the actuator from the valve with an extractor

that can be ordered from the manufacturer. See Sec-

tion 8 ’Tools’.

Remove the bracket.

4.5 Removing the valve from the pipeline

Make sure that the pipeline is empty and unpressu-

rized and that there is no medium flowing to the

pipeline while the valve is being serviced.

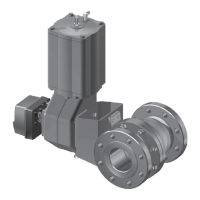

Carefully attach the ropes, loosen the pipe flange

screws and lift the valve using the ropes. Make sure that

you lift the valve correctly. See also Fig. 12.

4.6 Dismantling the valve

4.6.1 Sizes 1" - 8" (XT/XA), 8" (XB/XC)

Place the valve so that the body’s hexagon nuts (16) /

body cap (2) point upwards. Use a surface that does

not damage the flanges.

Mark the body halves for correct orientation during

reassembly.

Loosen the gland nut (18).

Turn the ball to the closed position.

Loosen the body nuts (16).

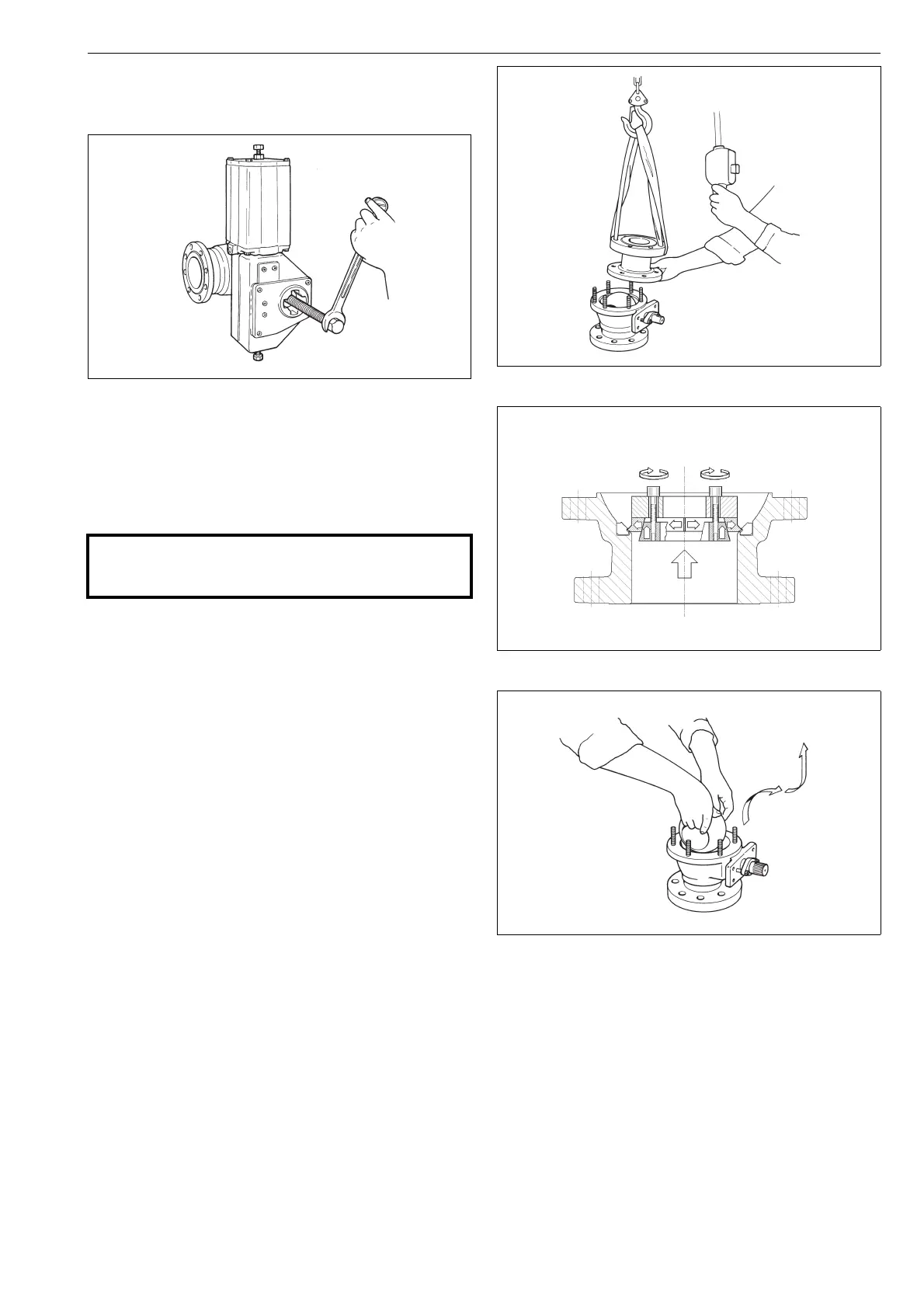

Remove the body cap (2) from the valve. Should the

ball seat (7, 25) not stay on the body cap, keep it

from falling while you are lifting it out by putting

your fingers under the body cap (small sizes) or in

the flow bore (large sizes). Watch out for your hand!

Lower the body cap onto the surface in a standing

position, i.e. onto its flange. See Fig. 19.

Remove the seat (7, 25) from the body cap making

sure that it is not damaged during the operation. If the

seat is of a locked type, use a special tool which can be

ordered from the manufacturer. See Fig. 20 and Sec-

tion 8 ’Tools’.

Remove the ball (3) from the body (1) by gripping

the edges of the flow bore (small sizes) or by passing

a rope through the bore (large sizes). To detach the

ball from the spline driver (4) in sizes 2"-8" or from

shaft/thrust ring (4) in sizes 1"-1 1/2", turn the ball to

the closed position before lifting. Make sure that the

ball is not damaged and put it onto a soft surface.

See Fig. 21.

Remove the key (10).

Remove the gland nuts (18), spring set (150), one

stud (14), retaining plates (42) and gland (9). Remove

Fig. 18 Detaching a B series actuator with an extractor

CAUTION:

Do not dismantle the valve or remove it from the pipe-

line while the valve is pressurized!

Fig. 19 Lifting the body cap

Fig. 20 Removing a locked seat

Fig. 21 Removing the ball from the body

Loading...

Loading...