AUTOMATION TESTING AND COMMISSIONING

––– STEP 8 –––

SETTING THE ELECTRICAL LINE

FOR PERMANENT POWER SUPPLY

After programming, before testing and commissioning the automation, it

must be permanently connected to the mains by means of a special pow-

er line equipped with a disconnect device.

8.1 - CONNECTING THE AUTOMATION PERMANENTLY

TO THE POWER MAINS

CAUTION! – Incorrect connections can cause faults or hazardous

situations; therefore strictly observe all connections specified in this

paragraph.

8.1.1 - Replacement of the power cable

01.Remove the power supply unit

To perform this operation, read the instructions in paragraph A.2

(chapter “Further details”), but only disconnecting the wires phase

and neutral (there is no need to disconnect the earth wire or connec-

tor with the 5-cable plate).

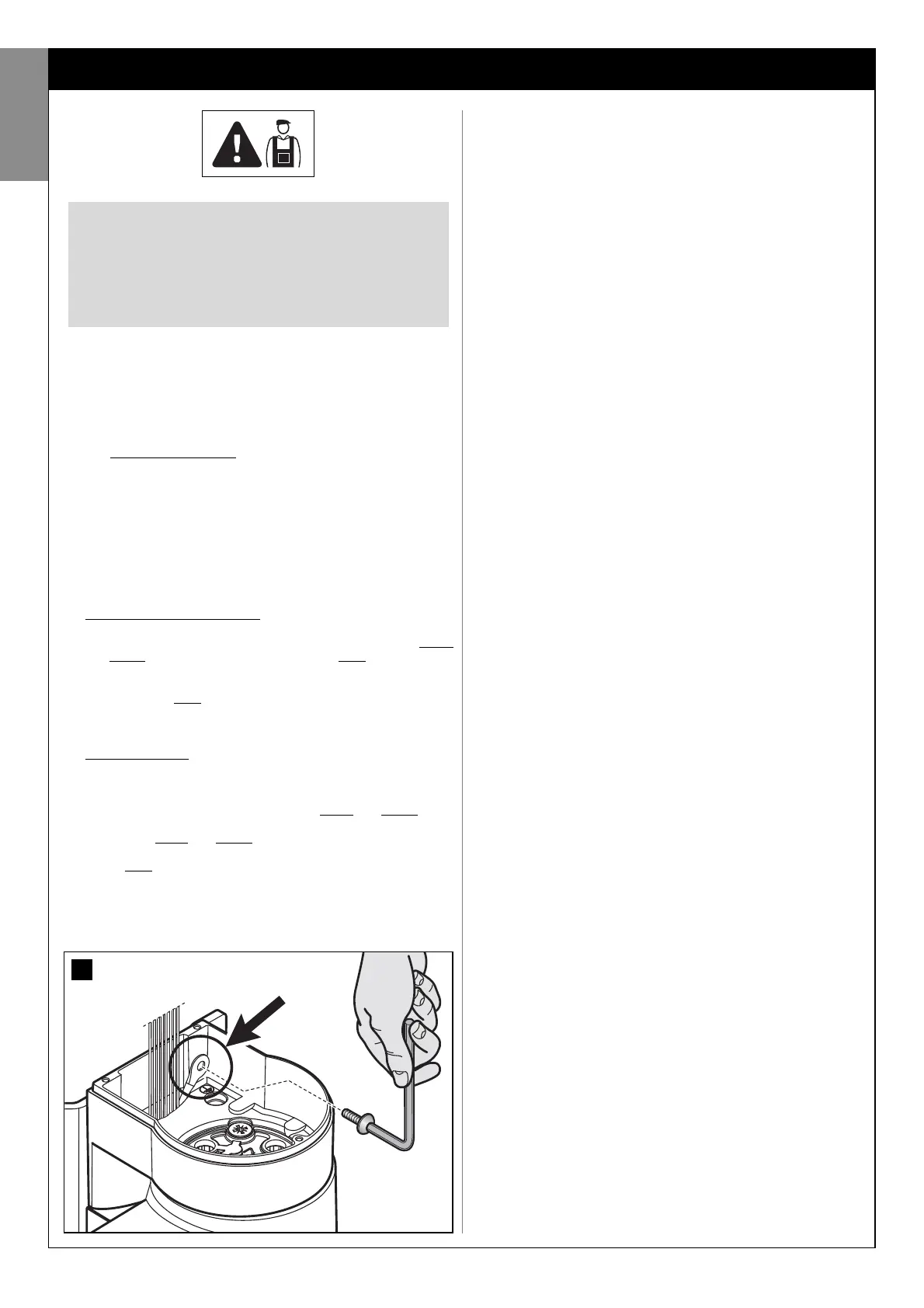

02.In the area housing the power supply unit, remove the screw securing

the eyelet of the earth wire (fig. 30).

03.Remove the control unit

To perform this operation, read the instructions in paragraph A.1

(chapter “Further details”).

04.Replace the cable

Loosen the cable clamp screws; withdraw the power cable (supplied

as standard) and insert the new cable (for cable specifications, refer

to paragraph 3.3.4).

05.Strip the cable to approx. 80 mm, and the phase and neutral wires,

after which insert the sheath taken from the previous power cable.

06.Connect the phase and neutral wires to the power supply unit termi-

nal board, observing the specifications on the label.

07.On the earth wire, insert a crimp terminal without insulation, using a 6

mm eyelet.

08.In the area housing the power supply unit, use a screw to secure the

two eyelets for the earth wires (fig. 30 – Caution! - Direct the crimp

terminal towards the outlet of the power cable).

CAUTION! – All operations described in chapters 8,

9, 10 may constitute a hazard. Therefore they must

be performed exclusively by skilled and qualified

personnel, in observance of these instructions and

current safety standards applicable in the place of

use.

09.Slowly pull the power cable downwards until a sufficient cable length

is left to rotate and close the power supply unit.

10.Then, firmly position the seal in its seat and close the power supply

unit cover with all screws (caution! - A missing seal or screw may

cause problems with internal electronics).

11.Lastly, tighten down the screws of the cable clamp, insert the control

unit in its seat, refit the cable ducting support and refit the lower cov-

er of the gearmotor.

8.1.2 - Installing the safety devices on the electrical line

The automation power line must be equipped with a device for protection

against short circuits and a device for disconnection of the automation

from the power mains (neither devices are supplied with the kit).

The disconnect device must have contacts with a sufficient gap to ensure

complete disconnection, in compliance with the overvoltage category III,

according to the installation instructions.

If necessary, this device guarantees quick and safe disconnection from

the mains power and therefore must be positioned in sight of the automa-

tion. If located in a concealed position, it must be equipped with a system

that prevents inadvertent or unauthorised reconnection of power, to avoid

potential hazards.

––– STEP 9 –––

AUTOMATION TESTING

AND COMMISSIONING

Testing and commissioning of the system are the most important phases

in automation set-up, as they will guarantee maximum system safety. The

testing procedure described below may also be used to periodically

check the devices making up the automation.

Testing and commissioning of the entire system must be performed

by skilled and qualified personnel, who are responsible for the tests

required to verify the solutions adopted according to the risks pres-

ent, and for ensuring observance of all legal provisions, standards

and regulations and in particular all requirements of the standard EN

12445, which establishes the test methods for checking automations

for gates.

9.1 - TESTING

01.Ensure that all instructions and warnings in STEP 1 have been strictly

observed.

02.Using the selector or radio transmitter, test a gate closing and open-

ing cycle and ensure that the leaf movement corresponds to specifi-

cations. A number of tests should be performed to ensure that the

gate moves smoothly and that there are no assembly defects, incor-

rect settings, or any points of friction.

03.Ensure correct operation of all safety devices in the system (photo-

cells, sensitive edges, etc.), by activating them one at a time during an

opening and/or closing manoeuvre. In particular, each time a device is

activated, check on the control unit that the Led “ECSBus” emits a

longer flash; this confirms that the control unit has recognised the

event.

04.To test photocells and in particular that there is no interference with

other devices, pass a cylinder (diameter 5 cm, length 30 cm) through

the optic axis (fig. 31). Pass the cylinder first close to the TX photo-

cell, then close to the RX and lastly at the centre between the two.

Ensure that in all cases the device engages, changing from the active

status to alarm status and vice versa, and that the envisaged action is

generated in the control unit (for example movement inversion in the

Closing manoeuvre).

05.Measure the force as specified in the standard EN 12445. If the motor

force control is used as an auxiliary function for reduction of impact

force, test and identify the setting that obtains the best results.

9.2 - COMMISSIONING

Commissioning can only be performed after positive results of all test

phases. Partial or “makeshift” commissioning is strictly prohibited.

01.Produce the technical documentation of the automation, which must

include at least the following documents: the overall layout drawing

of the system (see example in fig. 4), the electrical wiring diagram

(see example in fig. 26), the analysis of risks present and relative

solutions adopted, and the manufacturer’s declaration of conformity

of all devices installed (use appendix 1).

02.Affix a dataplate on the gate, specifying at least the following data:

type of automation, name and address of manufacturer (responsible

30

English

22 – English

Loading...

Loading...