GRAPH 3 (see paragraph 3.4)

EXAMPLE: if a maximum opening

angle of 105° is required, and value B on

the gate post is measured at 145 mm,

value A can be selected from one of the

values from 125 to 150 mm or from 185

to 210 mm. In both cases, the minimum

value is recommended.

(compatible A values)

the gearmotor is to be positioned.

a) - On Graph 3 locate the line marked with the same maximum opening

angle as that measured.

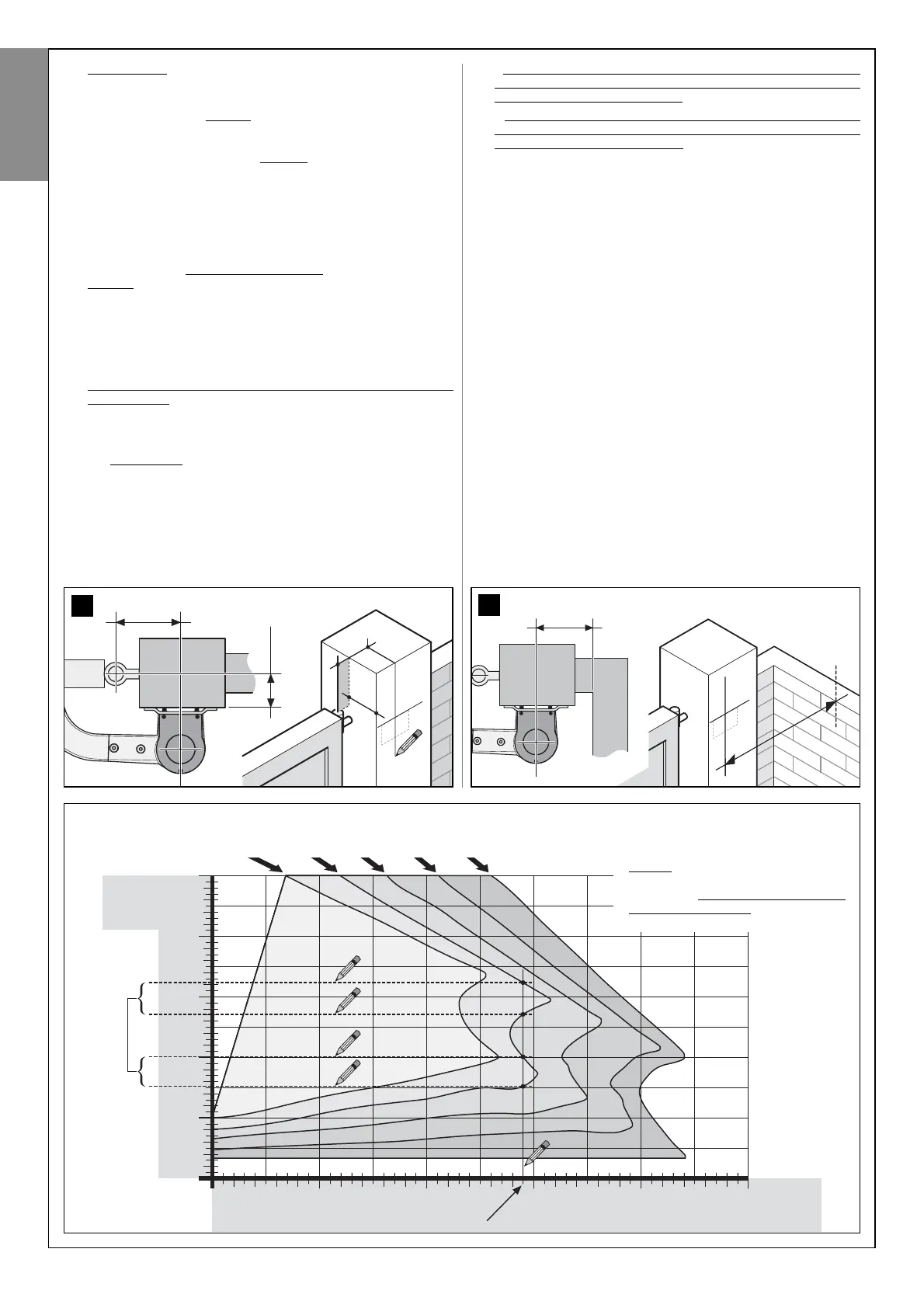

b) - On the post, measure value B (fig. 11), i.e. the distance between the

fulcrum of leaf rotation (centre of the hinge pin) and the post surface

where the gearmotor is to be fixed.

c) - On Graph 3 note the obtained value B on the horizontal axis and

from this point, trace a vertical line until it intersects the line with your

maximum leaf opening angle (see example in graph).

d) - On Graph 3 trace a horizontal line passing through each point of

intersection created between the previously traced vertical line and

the line with your maximum leaf opening angle.

Then on the vertical axis, read all values of “A” including those

between the traced horizontal lines (see example in graph) and where

feasible select the minimum possible value. This will be the required

value A.

e) - On the post, note the selected value “A” and trace a vertical line from

this point (fig. 11). The line must intersect the horizontal line already

present; these two lines will serve as a reference for subsequent fix-

ture of the gearmotor.

f) - Lastly, release the gearmotor with reference to the chapter “Manually

locking and releasing the gearmotor”, in the “Operation Manual”.

05. Determining the procedure to be followed to complete gearmo-

tor installation.

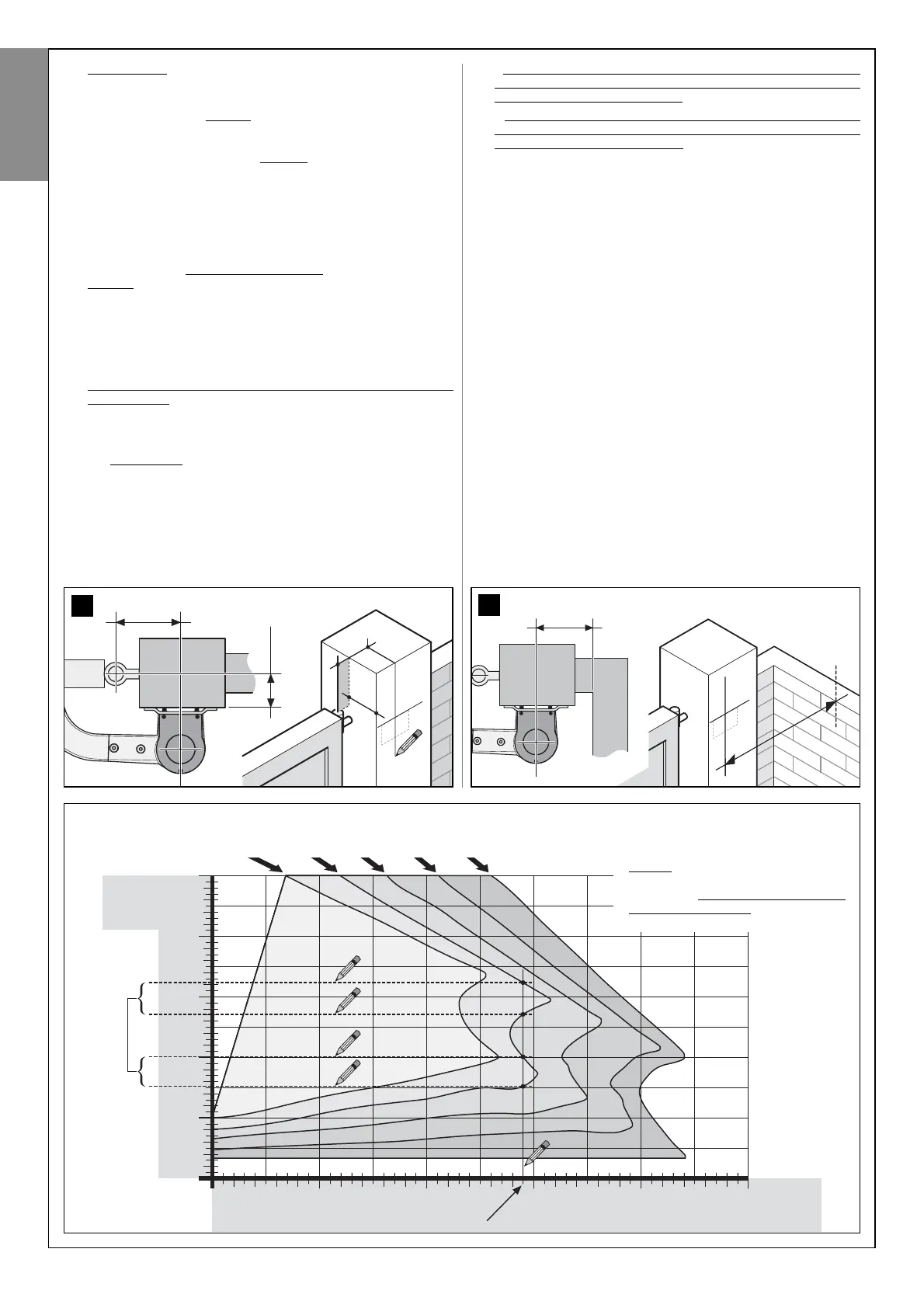

a) - CAUTION, VERY IMPORTANT! At this point if there is a wall,

pole or other fixed element behind the post, to determine

whether this may obstruct complete rotation of the arm, meas-

ure distance E

(fig. 12), i.e. the space between the previously

traced vertical line on the post at the closest point of the obsta-

cle. Then,

- if

distance E is between 80 mm (minimum) and 299 mm (max-

imum), continue installation according to procedure 4.1B. (this

envisages shortening of the arm);

- if distance E is equal to or greater than 300 mm, continue

installation according to procedure 4.1A (this envisages the

standard arm length as supplied).

Loading...

Loading...