If there is no response from any of the following tests, refer to

the main Wiring Diagram on the next page to locate the next

connector in line to ward the con sole and repeat the test at

that con nec tor. If there is a response at that connector, the

problem may be in the cable between the two connectors

(or the con nec tors themselves).

SPEED INPUT

Turn rotary dial to speed po si tion and dis con nect the

speed sensor (yel low tie) from the main harness. Check

for 12 volts between pins B (white) and C (black) of the

main harness speed cable (yellow tie). Using a clip lead

or other jumper wire (such as a paper clip bent in a “U”),

several times rap id ly short to geth er pins A (red) and C

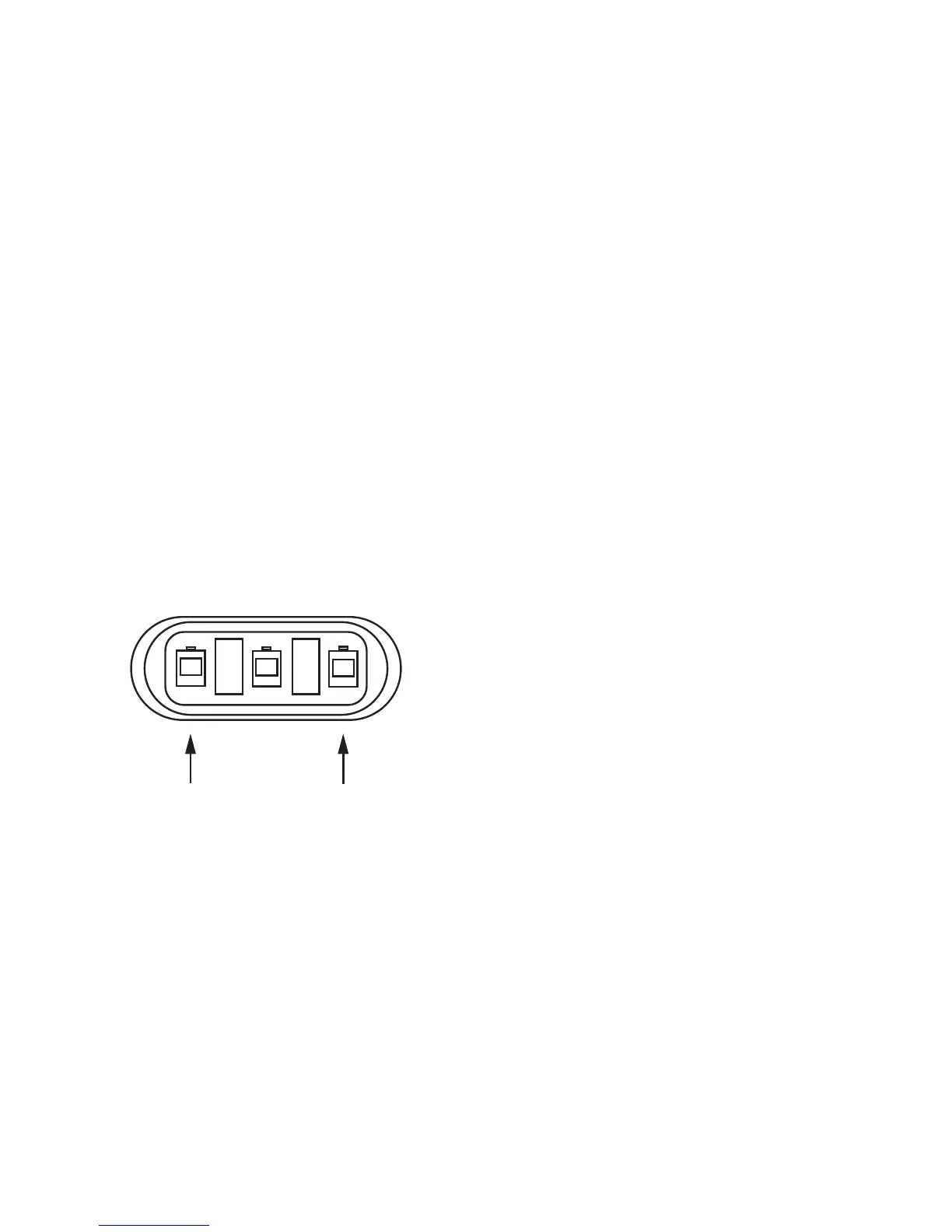

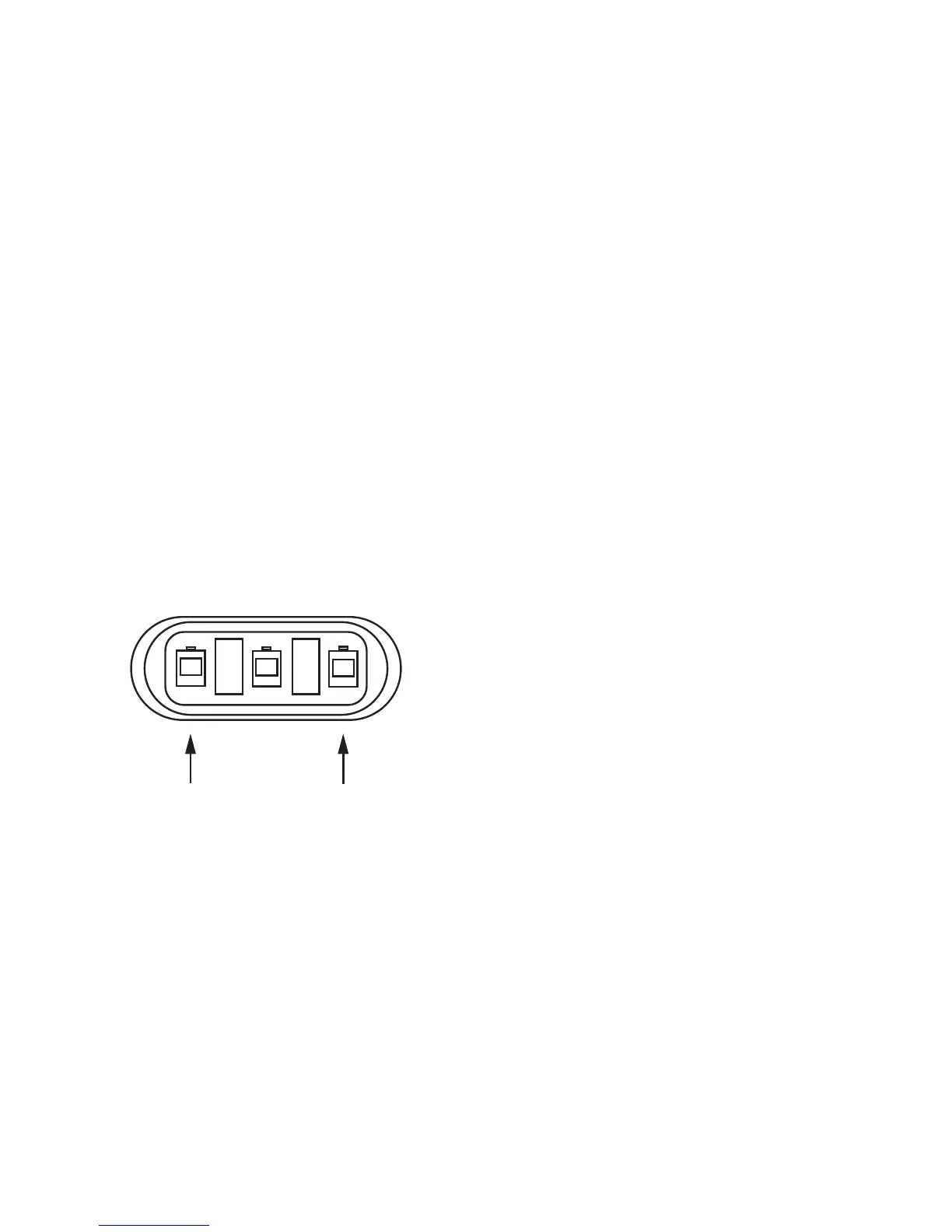

(black) of the 3-pin connector (See Illustration 36). The

console should respond with some speed read ing.

FLOW INPUT

Turn rotary dial to flow rate (not spray rate) and disconnect

the flow sen sor (green tie) from the main harness. Check

for 12 volts be tween pins B (white) and C (black) of the

main harness flow cable (green tie). Using a clip lead or

other jumper wire (paper clip bent in a “U”), several times

rapidly short together pins A (red) and C (black) of the

3-pin connector (See Illustration 36). The con sole should

re spond with some flow rate reading.

REMOTE RUN/HOLD INPUT

Disconnect the remote run/hold sensor (or jumper cover)

from the main harness. Check for 12 volts between pins

B (white) and C (black) of the main harness remote

run/hold cable (gray tie). With the consoles Run/hold

switch in RUN, place a clip lead or other jumper wire

(such as a paper clip bent in a “U”) between pins A (red)

and C (black) of the main harness run/hold connector

(gray tie) should turn off the “HOLD” indicator on the

console display. Removing the jumper should turn on

the “HOLD” indicator on the console display.

FLOWMETER

Shaking the Flowmeter end to end should pro duce a “rattling”

sound (shaft end play). Blowing in the meter from either end

should spin the turbine freely. If the turbine spins freely but

the meter will not register flow with a known working sensor,

the turbine may be defective. See Appendix D for Flow me ter

Clean ing and Assembly details.

39

Troubleshooting (cont)

Console Inputs

ELECTRIC BOOM VALVES

To configure your system to use 2-wire motorized ball valve

shut-offs, remove the jumper cover from the 2-pin connector

on the main console harness. See Wiring Diagram on the next

page. If you are using solenoid valves, do not remove jumper

cover. If 12 volts are present between the two harness

wires to valves, but valves will not activate, consult valve

manufacturer’s troubleshooting instructions.

SERVO VALVE CONTROL SIGNAL

Flip the power switch to ON, put the console in MANUAL

mode, place the Run/Hold switch in the RUN position and

turn all boom switches to ON. Using a voltmeter, check

from a good frame ground to each of the servo wires on

the main harness connector. There should be about six

volts on each wire. Holding the “+” button should cause

one wire on the three-pin connector to pulse from six

toward four volts and the other wire on the three-pin

connector to pulse from six toward eight volts. Holding

the “-” button should show the opposite results.

SERVO VALVE

The best way to test the servo valve is with a known working

console. Flip the power switch to ON, put the console in

MANUAL mode, place the Run/Hold switch in the RUN

position and turn all the boom switches to ON. With the

servo valve connected to the servo valve lead on the main

harness, holding the “+” button should close the servo valve

and holding the “-” button should open the servo valve

(provided the console has passed the Servo Valve Control

Signal test).

NOTE: The opposite should result if calibrated for inline.

The servo valve should operate smoothly from fully open

to fully closed, in both directions.

You may also use a 9-volt transistor battery. Connecting the

battery to each terminal on the servo valve should cause the

servo valve to run in one direction. Reversing the battery

connections should cause the servo valve to run the other

direction. The servo valve should operate smoothly from end

to end, in both directions. DO NOT connect 12 volts directly

to the servo valve. Damage may result.

PLUMBING

Proper plumbing is a very important factor in obtaining

optimal performance from your MT-3405M system. The chart

on page 41 will help you determine what area of the plumbing

may be causing your problem. At this point, it is assumed that

your plumbing basically matches that of the System Diagram

on page 20 and that the servo valve and flowmeter are

known to be installed correctly and functioning properly. In

addition, make certain that you have selected and installed

the correct spray tips for the application, speed and spray

rate that you intend to maintain. Don’t forget the obvious

such as leaky fittings and hoses, pinched hoses and plugged

or worn nozzles. If you need more detail than the chart

provides, please refer to Plumbing Guidelines on pages 43

and 44.

PRESSURE SENSOR

The only way to field test the pressure sensor is to connect

it to a known working console, apply pressure and verify the

correct pressure reading on the console display.

The pressure sensor is a 4-20 mA (industry standard).

Three-Pin Connector

Illustration 36

Loading...

Loading...