OM-248965 Page 45

AG. UIM Bus Communication

— —

— —

— — Indicates no error message on the displays. UIM board PC7 DeviceNet is losing packets of data. Turn welding pow-

er source off and back on again to clear the communication error.

8-3. Troubleshooting

! Disconnect power before troubleshooting.

Trouble Remedy

Wire feeds, shielding gas flows, but

electrode wire is not energized.

Check and secure weld cable connections (see Section 5-2).

Electrode wire feeding stops or feeds

erratically during welding.

Check gun trigger connection. See gun Owner’s Manual.

Check gun trigger. See gun Owner’s Manual.

Readjust hub tension and drive roll pressure (see Section 5-6).

Change to correct size drive roll (see 5-6).

Clean or replace dirty or worn drive roll.

Incorrect size or worn wire guides.

Replace contact tip or liner. See gun Owner’s Manual.

Remove weld spatter or foreign matter from around nozzle opening.

Have Factory Authorized Service Agency check drive motor or motor control board PC1.

Motor runs slowly. Check for correct input voltage.

Wire feeder power is on, displays light

up, but unit is inoperative.

Check welding gun trigger leads for continuity, and repair leads or replace gun.

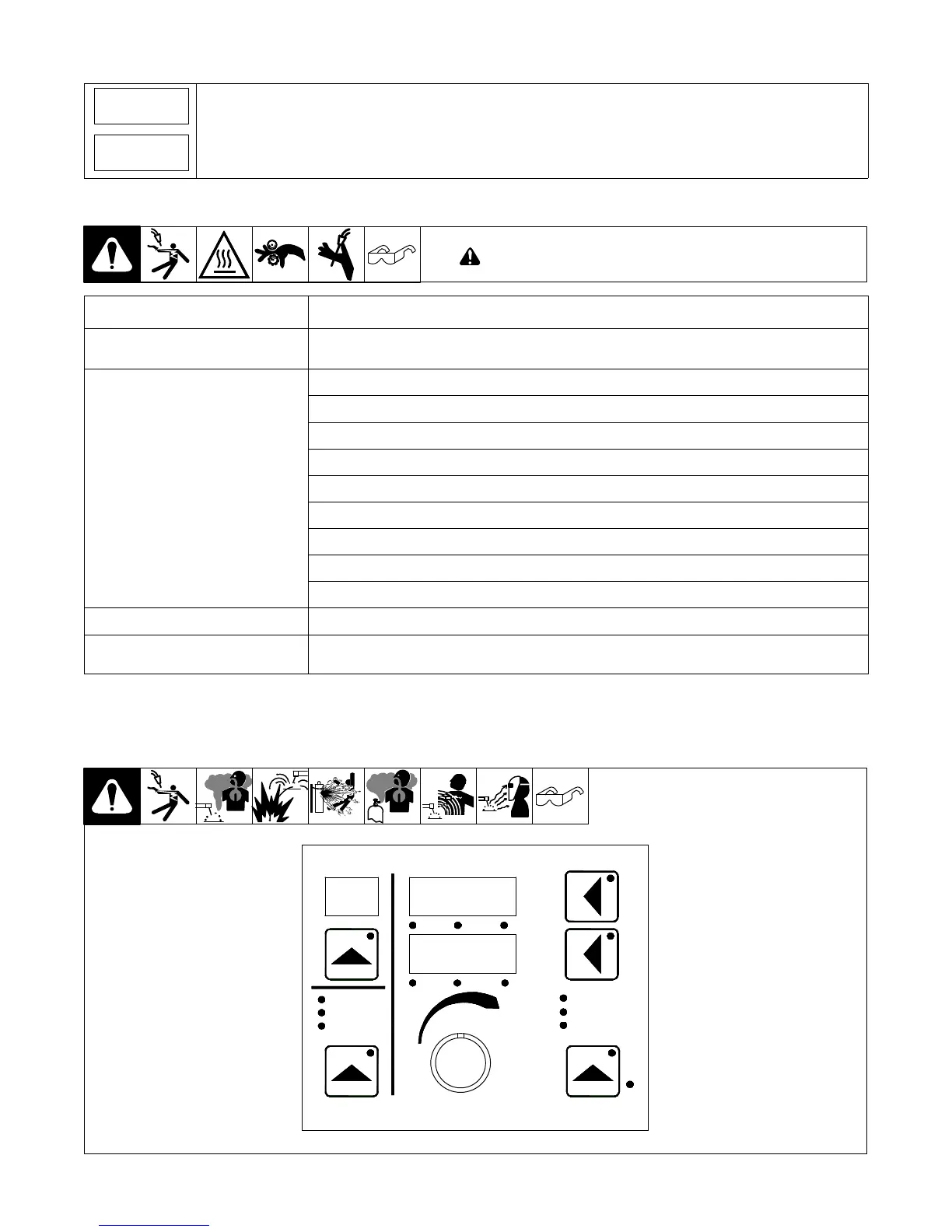

8-4. Check Web Message Display

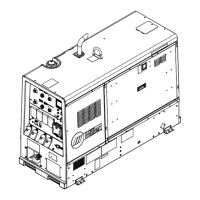

When an existing Axcess power source is upgraded to an Axcess E, the first time the unit is powered up the message

CHCK WEB will appear on the display (see Figure 8-1).

CHCK

WEB

Trigger Control

Program

Process

Wire Type

Gas Type

Process Set up

Volts Time Arc Adjust

WFS Amps Arc Ctl

Sequence

Trigger Hold

Adjust Feeder Set Up

1

Figure 8-1. Feeder Display On First Power Up After Upgrade

Loading...

Loading...