12.1 Performing an aggregate measure-

ment

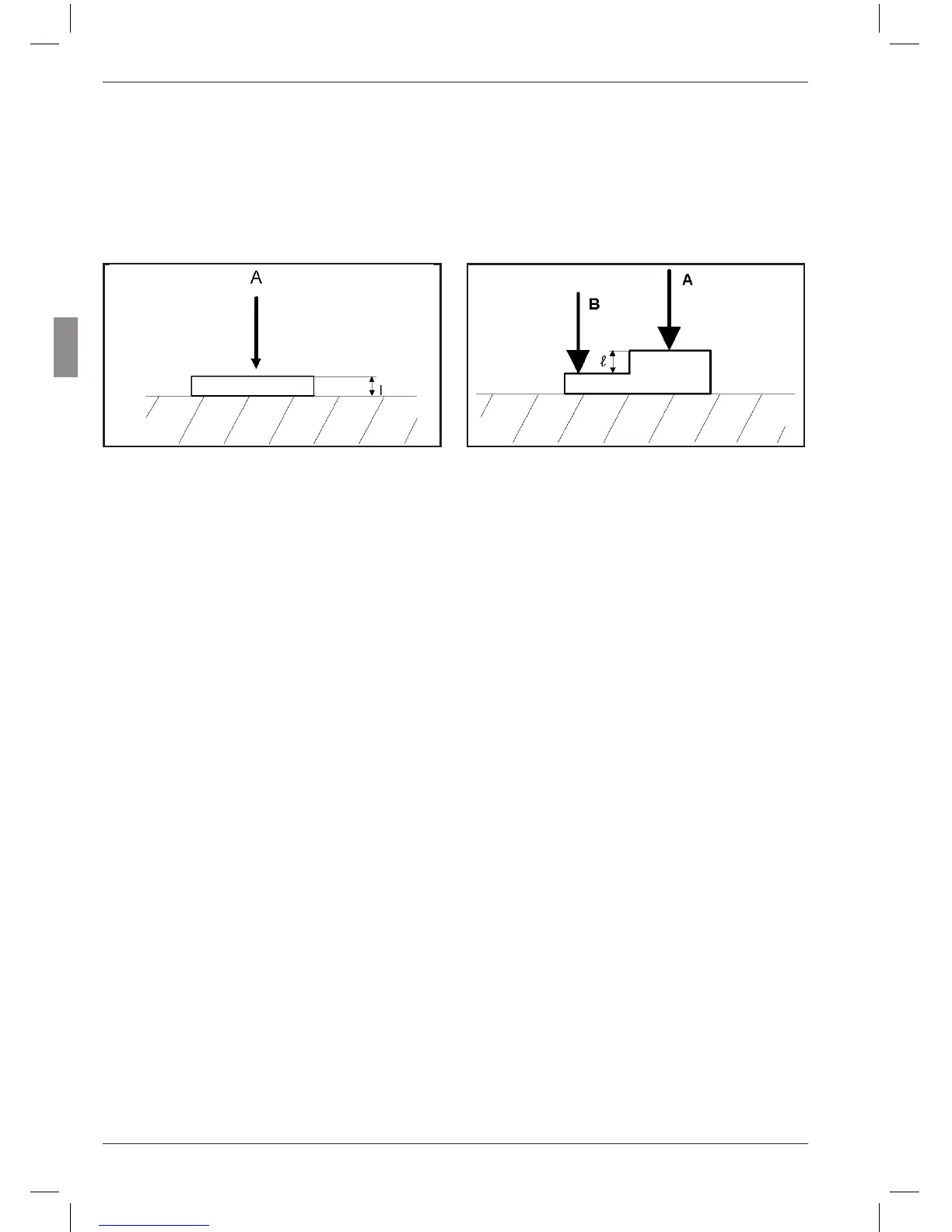

The thickness of a workpiece is to be measured.

Preset values

Nominal size: 12 mm

Tolerance: ± 0.080 mm

Gage block (Master): 11.998 mm

Millimar settings

MENU –> FEATURE (1.) – ....

FNCTION (1.2.) = NORMAL (1.2.1)

FORMULA (1.3.) = + C1 (1.3.1)

TOLER.+ (1.4.2.) = +000.080

TOLER.– (1.4.3.) = –000.080

NOMINAL (1.5.) = +012.0000

MASTER (1.8.)/

(MSTR.MAX) = +011.9980

Measuring sequence

1. Adjust the settings as detailed above.

2. Insert the gage block (master) into the mea-

suring device.

3. Press MASTER then START to calibrate the

measuring device with the gage block.

4. Remove the gage block (master) and insert

the workpiece into the measuring device.

5. Press START.

The thickness of the workpiece is displayed.

12.2 Performing a differential measure-

ment

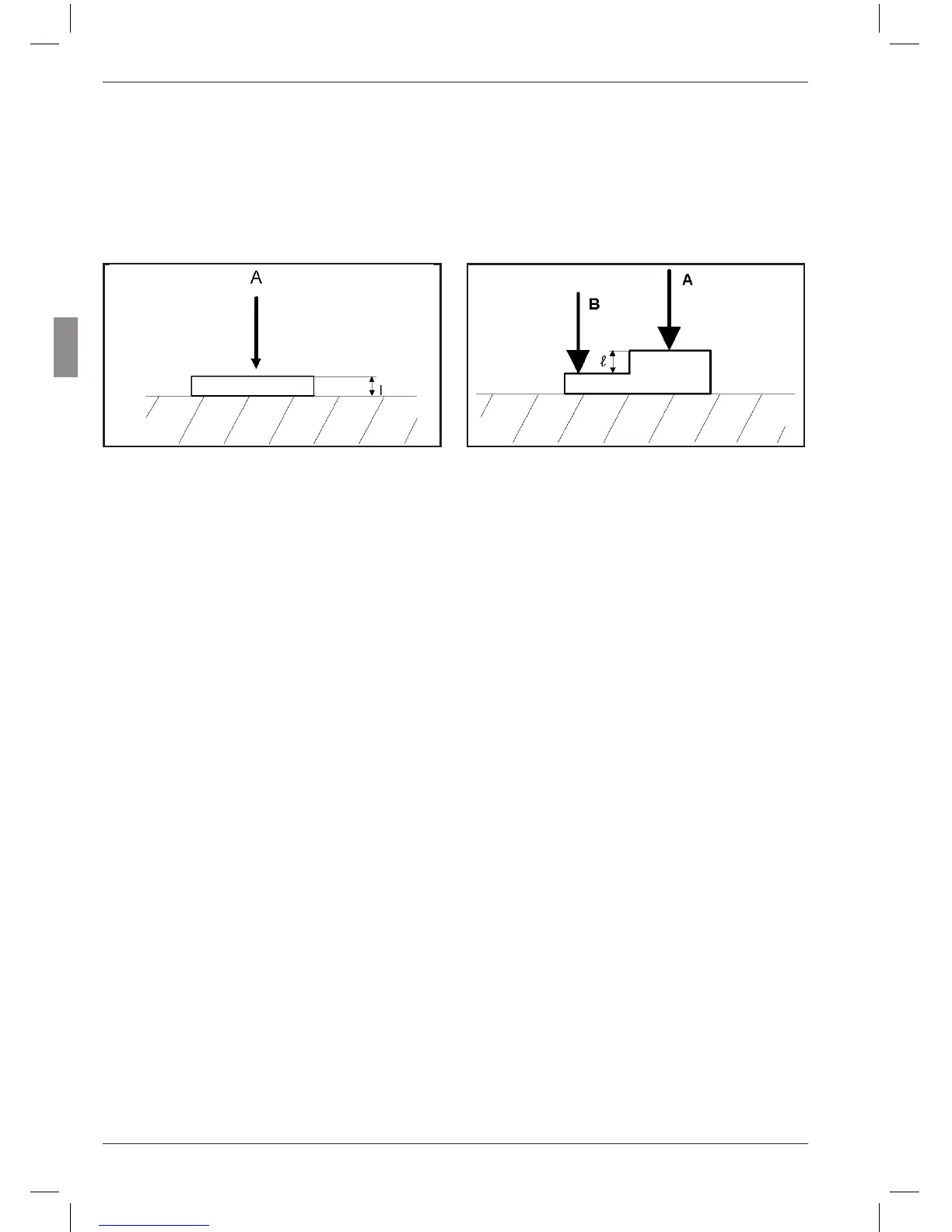

The height of a step is to be measured.

Preset values

Nominal size: 16 mm

Tolerance: +0.012/–0.008 mm

Gage block (Master): 16.002 mm

Millimar settings

MENU –> FEATURE (1.) – ....

FNCTION (1.2.) = NORMAL (1.2.1)

FORMULA (1.3.) = C1 – C2 (1.3.6)

TOLER.+ (1.4.2.) = +000.0120

TOLER.– (1.4.3.) = –000.0080

NOMINAL (1.5.) = +016.0000

MASTER (1.8.) .)/

(MSTR.MAX) = +016.0020

Measuring sequence

1. Adjust the settings as detailed above.

2. Insert the gage block (master) into the mea-

suring device.

3. Press MASTER then START to calibrate the

measuring device with the gage block.

4. Remove the gage block (master) and insert

the workpiece into the measuring device.

5. Press START.

The height of the step is displayed.

Loading...

Loading...