12.3 Performing a radial run-out

measure ment

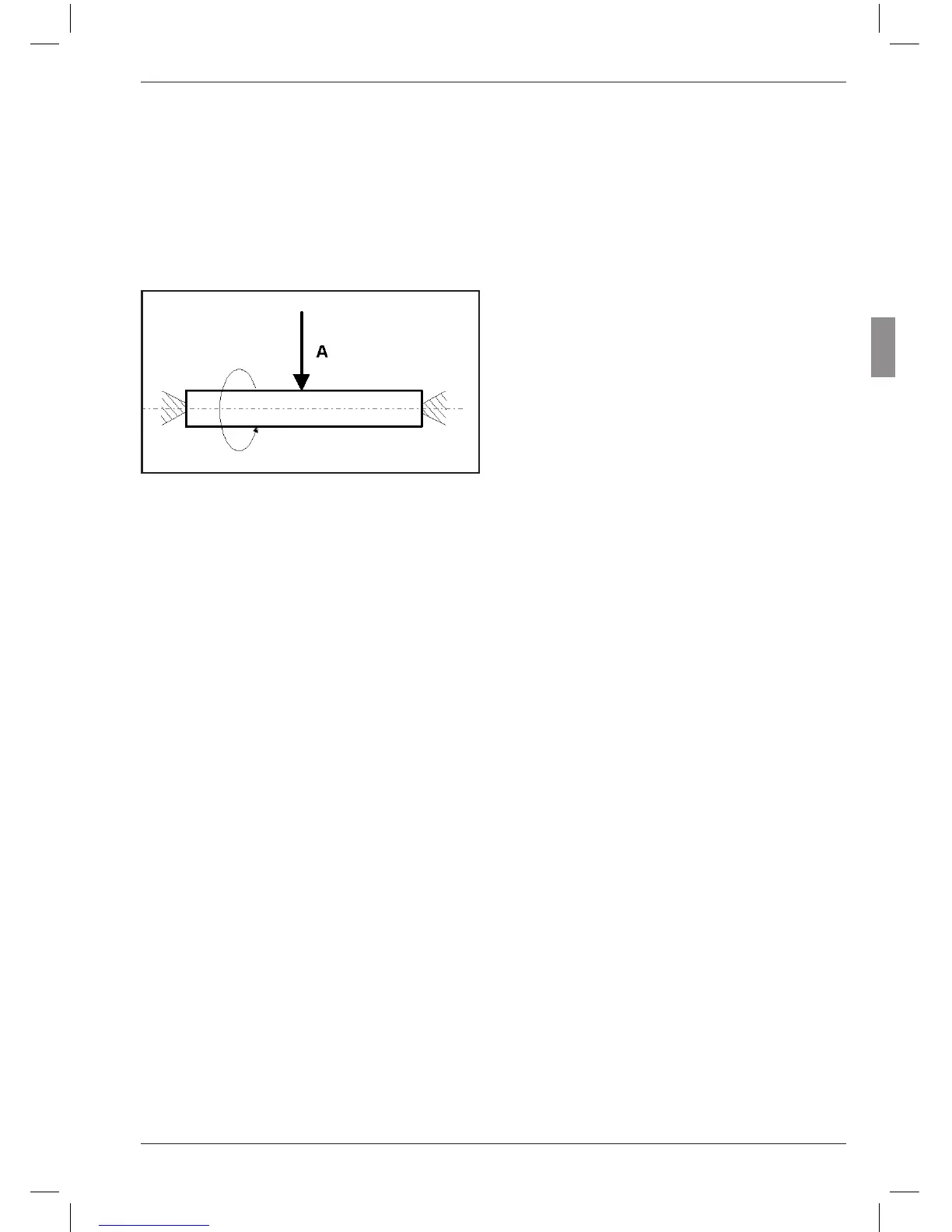

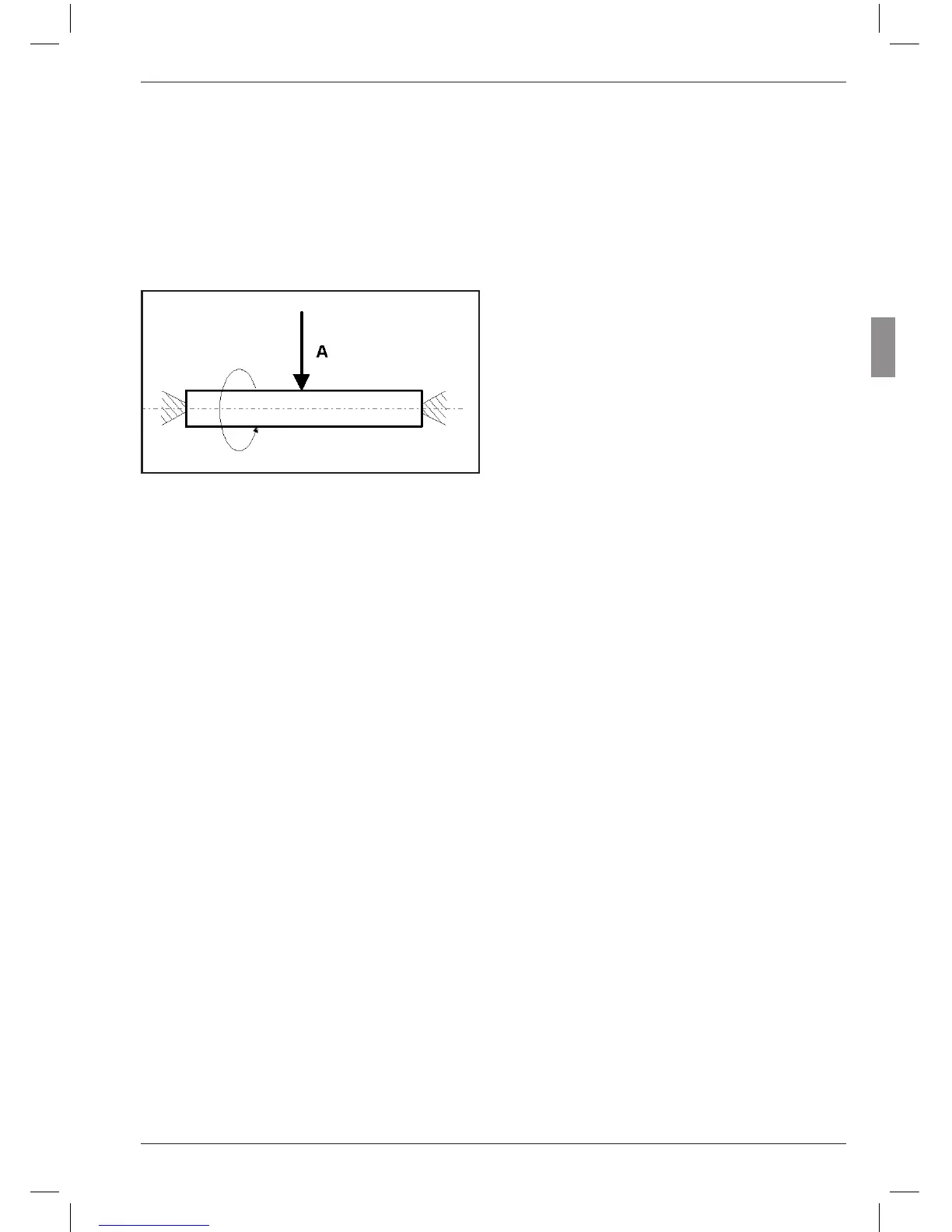

The radial run-out deviation to the centering tips

of a workpiece is to be measured.

Aggregate of unroundness and centricity.

Preset values

Nominal size: 0 mm

Tolerance: +0.016/–0.0 mm

Gage block (Master): 0.0 mm

Millimar settings

MENU –> FEATURE (1.) – ....

FNCTION (1.2.) = MAX–MIN (1.2.4)

FORMULA (1.3.) = +C1 (1.3.1)

TOLER.+ (1.4.2.) = +000.0160

TOLER.– (1.4.3.) = –000.0000

NOMINAL (1.5.) = +000.0000

MASTER (1.8.) .)/

(MSTR.MAX) = +000.0000

MENU –> PROCESS (3.) –> MEASURE (3.1.) –>

MEAS.MOD = AUTOM. (3.1.1.2)

Measuring sequence

1. Adjust the settings as detailed above.

2. Insert the gage block (master) into the mea-

suring device.

3. Press the START key to initialize measure-

ment. The MAX/MIN memories are wiped!

The display shows zero.

4. Turn the workpiece through one rotation.

5. Press START again. Measurement is ended.

The radial run-out deviation of the work-

piece is displayed.

Loading...

Loading...