Page 46 MiniRanger Plus 7ML19981CJ01

Applications

Pump Control Application

The basic difference between a simple level application and a pump control

application is that the relays assigned to pump function (P111) are normally

de-energized (off) and energized when required to run the pump. In the

program mode, pump relays are held de-energized.

Pumps can be programmed to work independently or in lead/lag fashion.

Refer to 36.

In applications where flooding is possible, a submersible transducer should

be used. The submersible transducer's air cavity insures that a high level

reading is maintained rather than establishing a loss of echo condition, when

the liquid level reaches the transducer. When using a submersible

transducer, set P802 = 1.

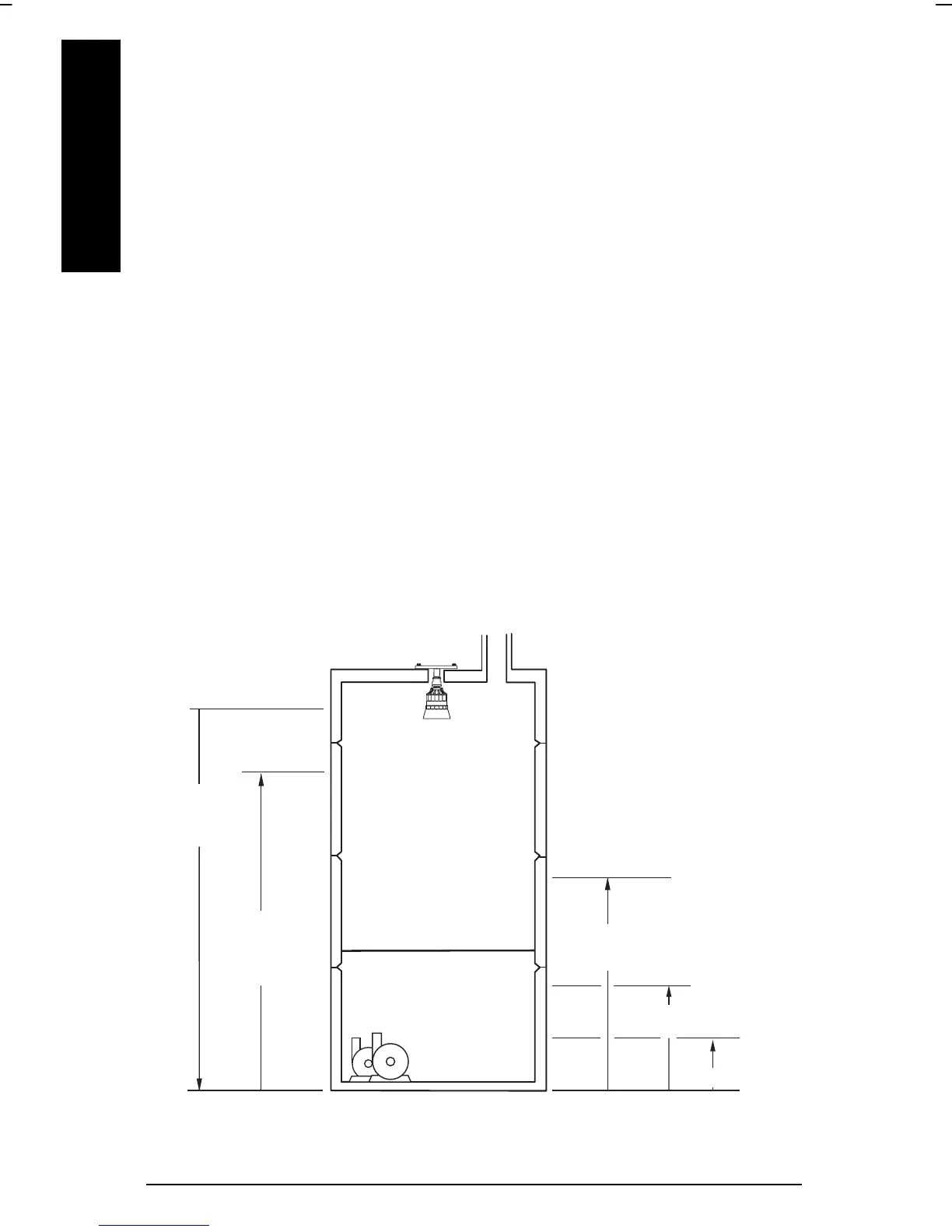

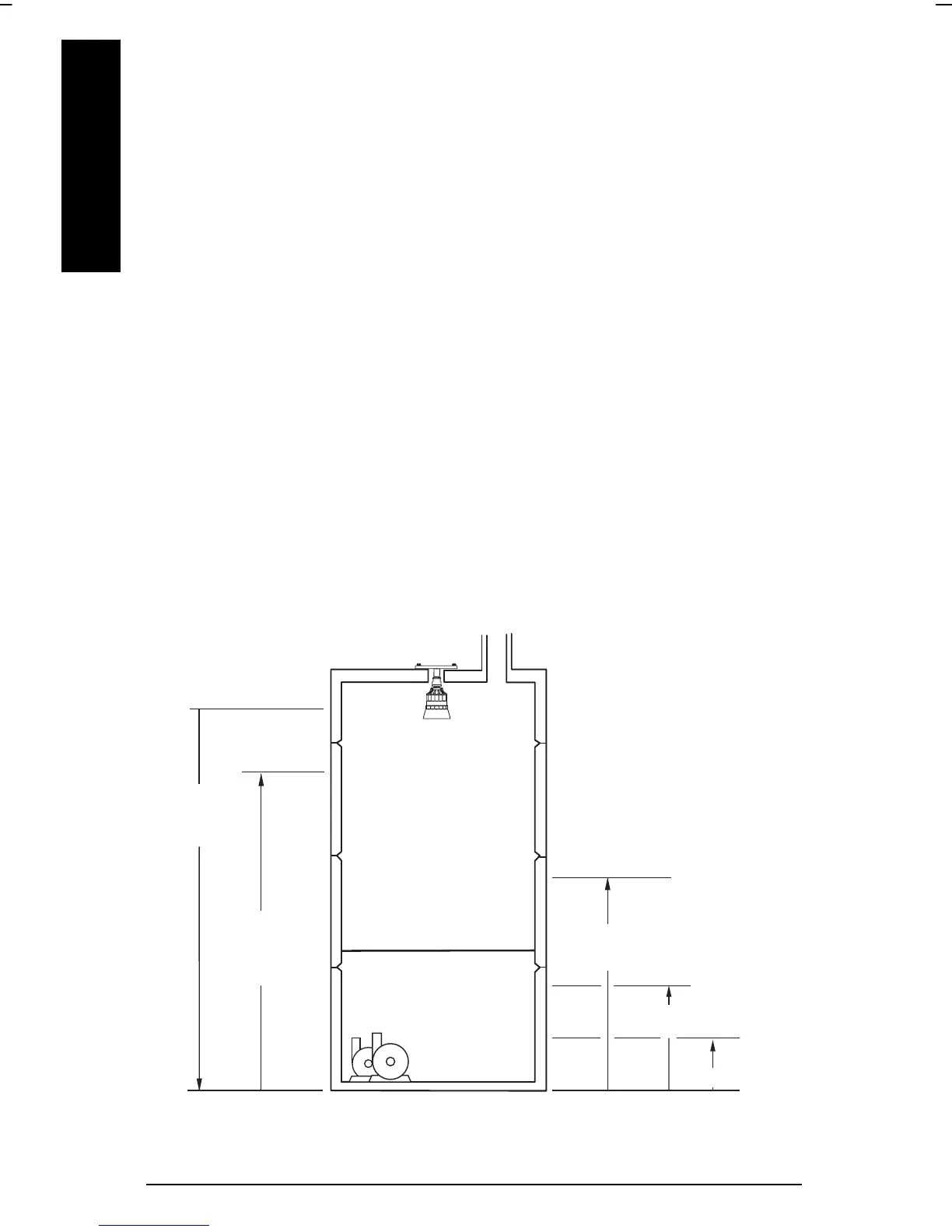

Example

The application is to control the level in a wet well. It is required that the level

be displayed in centimetres. The transducer is mounted at 3.6 m from the

bottom and is equipped with a submergence coupling as there is possibility

of flooding in the well. Two pumps are to be controlled by the MiniRanger

Plus in lead / lag fashion. The first pump to start at 1 m and the second

pump to start at 2 m. Both pumps are to stop at 0.25 m. The maximum

estimated filling rate is 1 m/min. In the event of a loss of echo, a fail-safe low

after 6 sec is required to protect the pumps from running dry.

P006

3.6m

P007

3.0m

relay 2,

pump on

P112-2, 1m

relay 1 & 2,

pumps off

P113-1&2, 0.25m

relay 1,

pump on

P112-1, 2m

Loading...

Loading...