1

SECTION 1

DESCRIPTION

1.1 INTRODUCTION

The mRoy pump is a highly reliable controlled vol-

ume pump of hydraulically actuated diaphragm

design. The XT and XW family of mRoy pumps are

described in this manual.

1.2 GENERAL

The mRoy pump capacity is adjustable while the

pump is running or stopped. Capacity adjustment

can be made by manually turning the control knob.

Repetitive accuracy of the metered discharge vol-

ume is maintained within a ±l% range at constant

conditions of pressure, temperature and pump

capacity adjustment setting.

The mRoy pump is a reliable, compact, controlled

volume diaphragm pumps for normal corrosive or

toxic chemicals and light slurries with viscosities up

to 200 S.S.U. (40 cps).

A plunger, reciprocating at a fixed stroke, displaces

a fixed volume of hydraulic fluid which actuates a

flexible, chemically inert PTFE diaphragm to create

pumping action. High quality ball check valves are

used on the suction and discharge to insure con-

sistent metering accuracy. Capacity control is

established by adjusting the volume of hydraulic

fluid which bypasses the diaphragm cavity.

Metering with repetitive accuracy is possible only if

the volume of the hydraulic oil in the displacement

chamber is maintained constant for each stroke.

This is accomplished by mechanically opening the

displacement chamber to the oil reservoir for a

short period at the end of every suction stroke and

the beginning of each pressure stroke. During this

period air or vapor is bled from the system, lost oil

is replenished, and allowances are made for the

expansion or contraction of the oil due to tempera-

ture change. For more information, refer to 1.3

Principle of Operation.

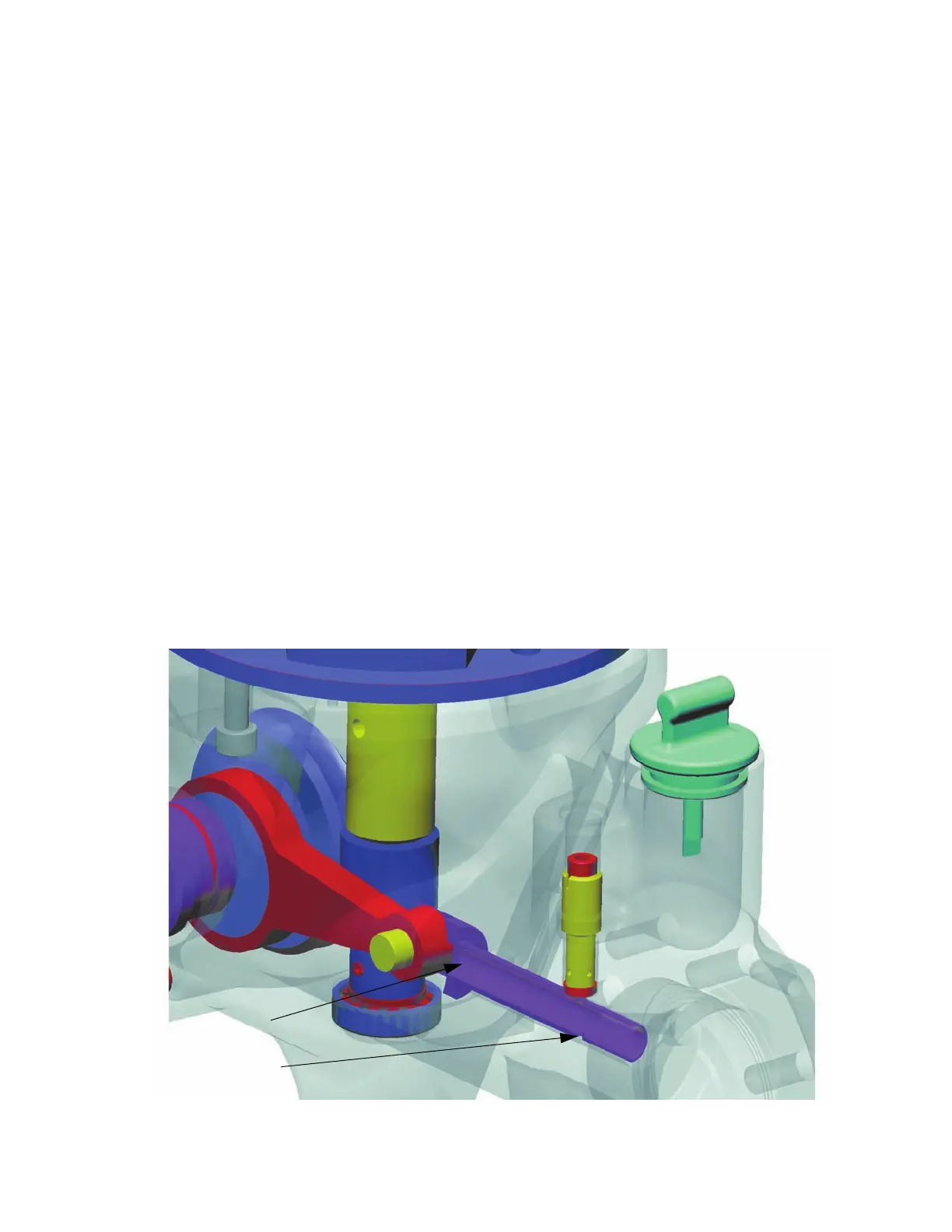

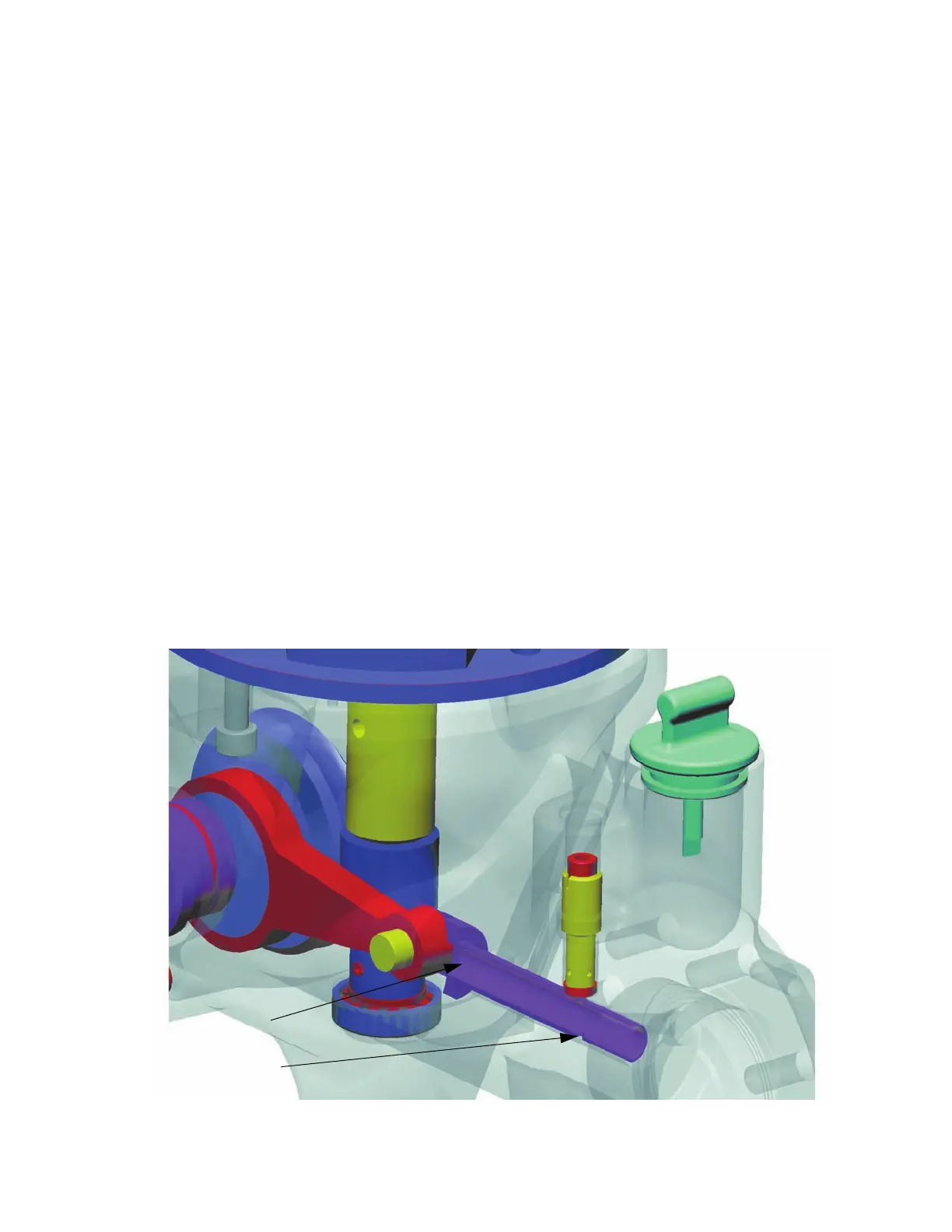

1.3 PRINCIPLE OF OPERATION (FIGURE 1)

Pumping action is developed and controlled by

three basic components as follows (Figure 1):

By-pass ports

in the Plunger

Plunger area shown with

stroke sdjust removed.

Hydraulic By-pass is through

the center of the Plunger

Figure 1. Pumping Action

Loading...

Loading...