4 SAFETY MONITORING FUNCTIONS

Safety Monitoring Functions 4-69

④ Monitoring Position

This enables selecting a monitoring position of the robot subject to position monitoring.

Selecting [Whole Arm and Tool] enables the position monitoring that uses an arm model and tool models

defined in 4.3 Defining 3D Models.

Selecting [Tool Only] enables the position monitoring that only monitors tool models.

⑤ Monitoring Function To Apply the Plane

This enables selecting monitoring functions (SLP1, SLP2, SLP3, SLPM) to which the monitoring plane

is applied. Multiple functions can be selected.

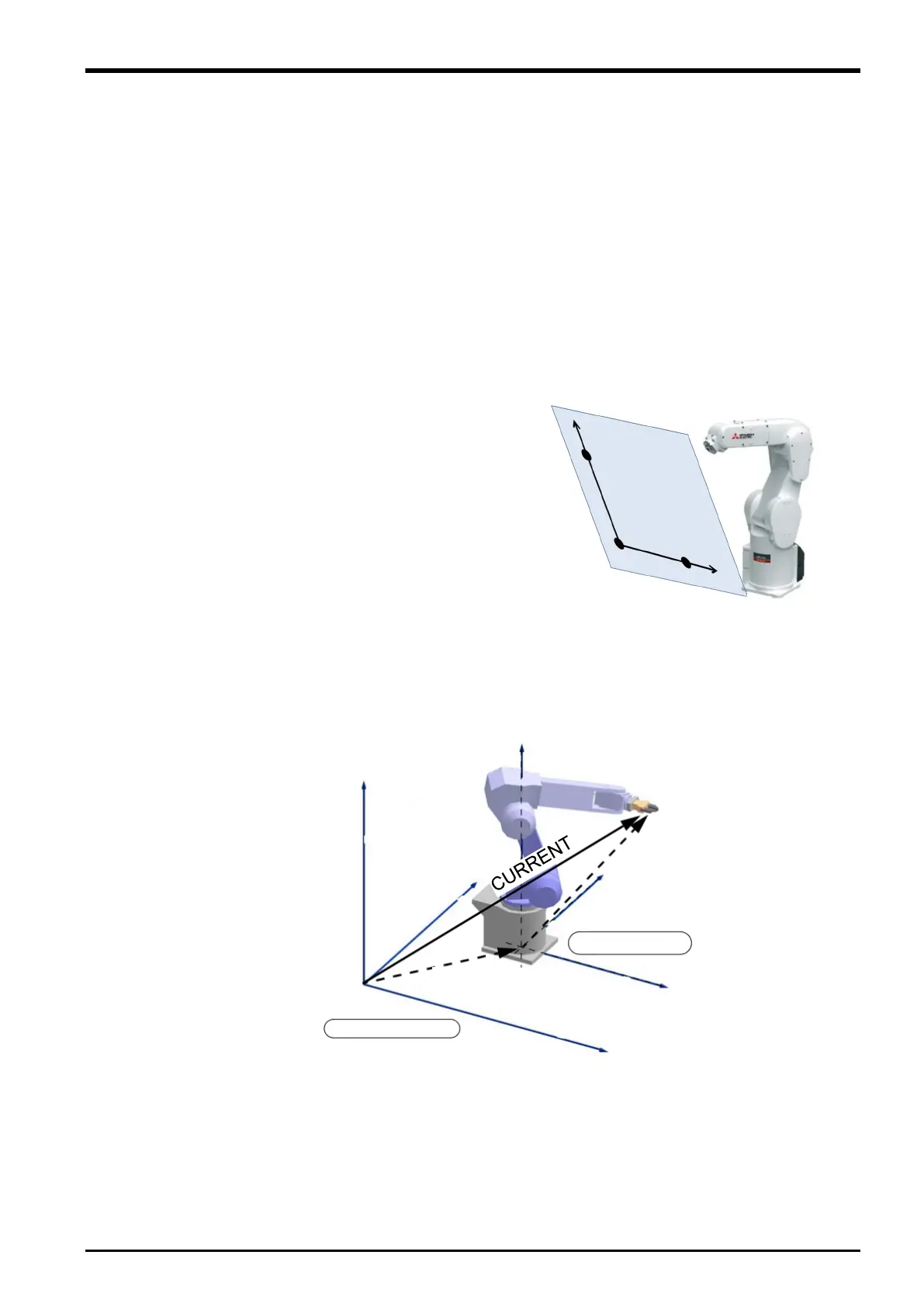

⑥ Plane Definition

As shown in the right figure, configure X, Y, Z

coordinates of the three points (origin, +X axis position,

+Y axis direction) on the defined plane in the base

coordinate system.

The plane is defined in the base coordinate system.

Therefore, the base conversion does not change the

relative position of the robot to the position monitoring

plane.

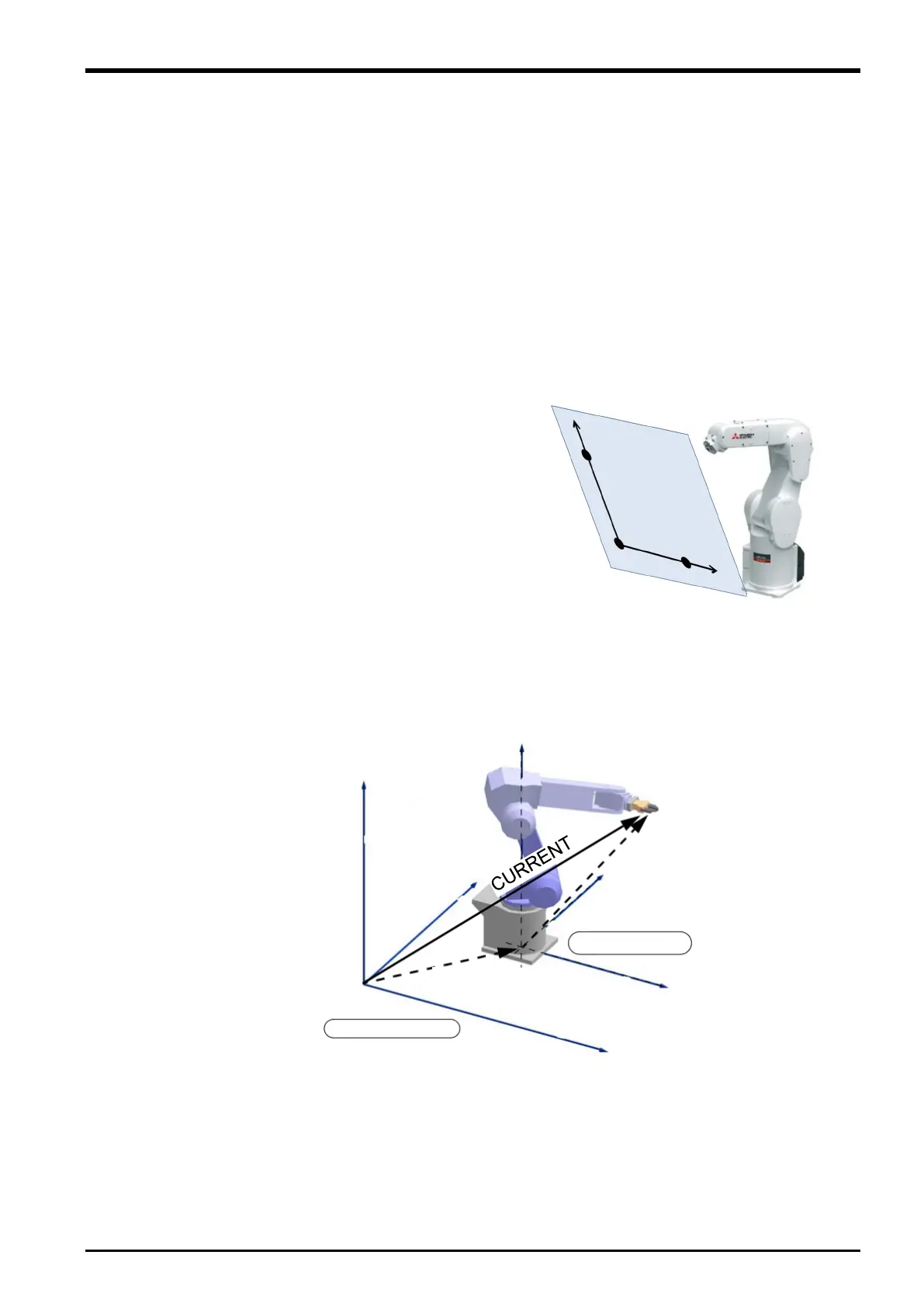

<Base coordinate system>

The base coordinate system is a coordinate system

based on the robot installation surface. The center of

the robot installation position (base data) in the world

coordinate system can be changed by using parameter

MEXBS or executing the Base command. By default,

the world coordinate system and the base coordinate

system are placed at the same position.

Fig. 4-59: Plane Definition

Fig. 4-60: Base coordinate system

+X axis

direction

Loading...

Loading...