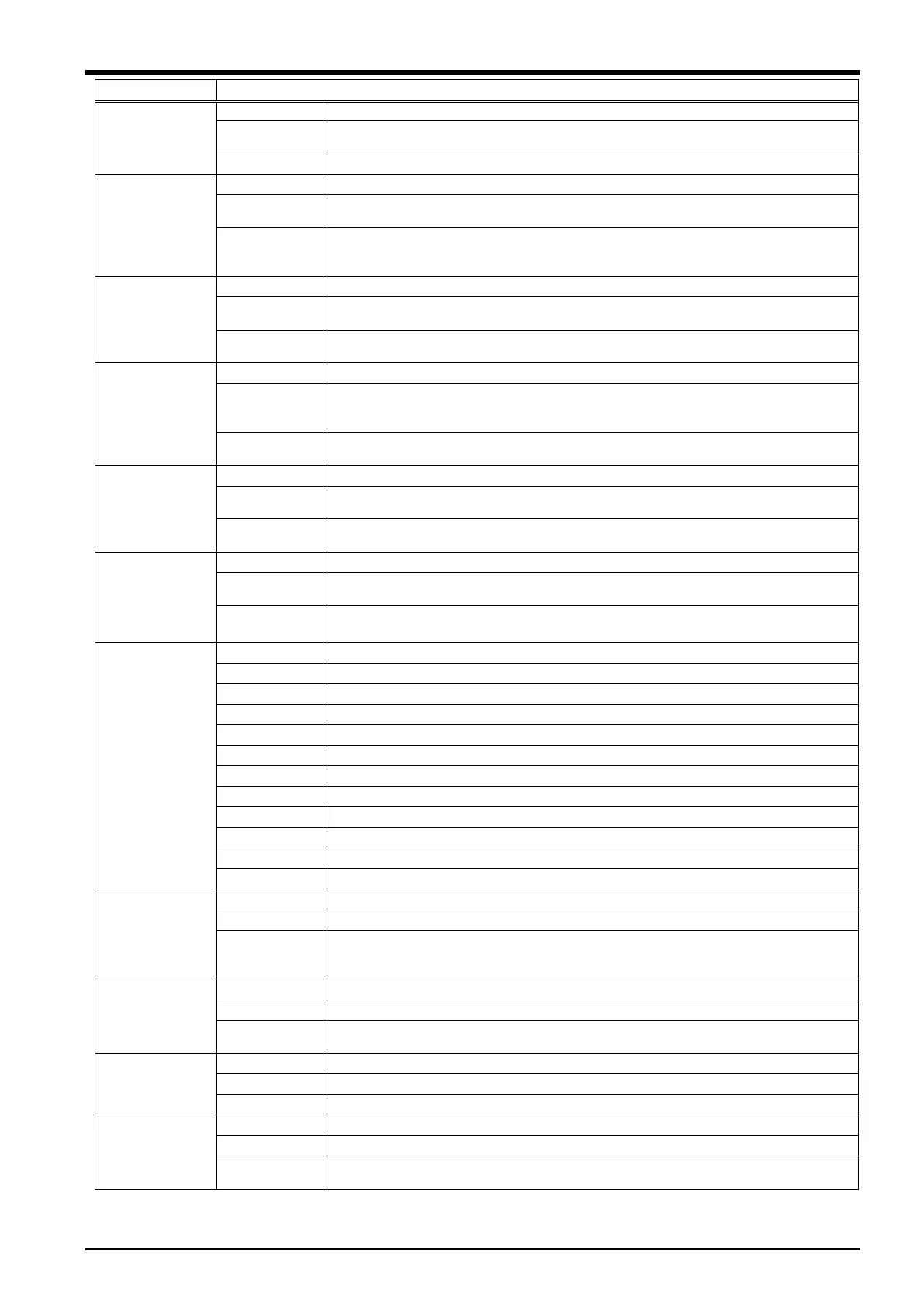

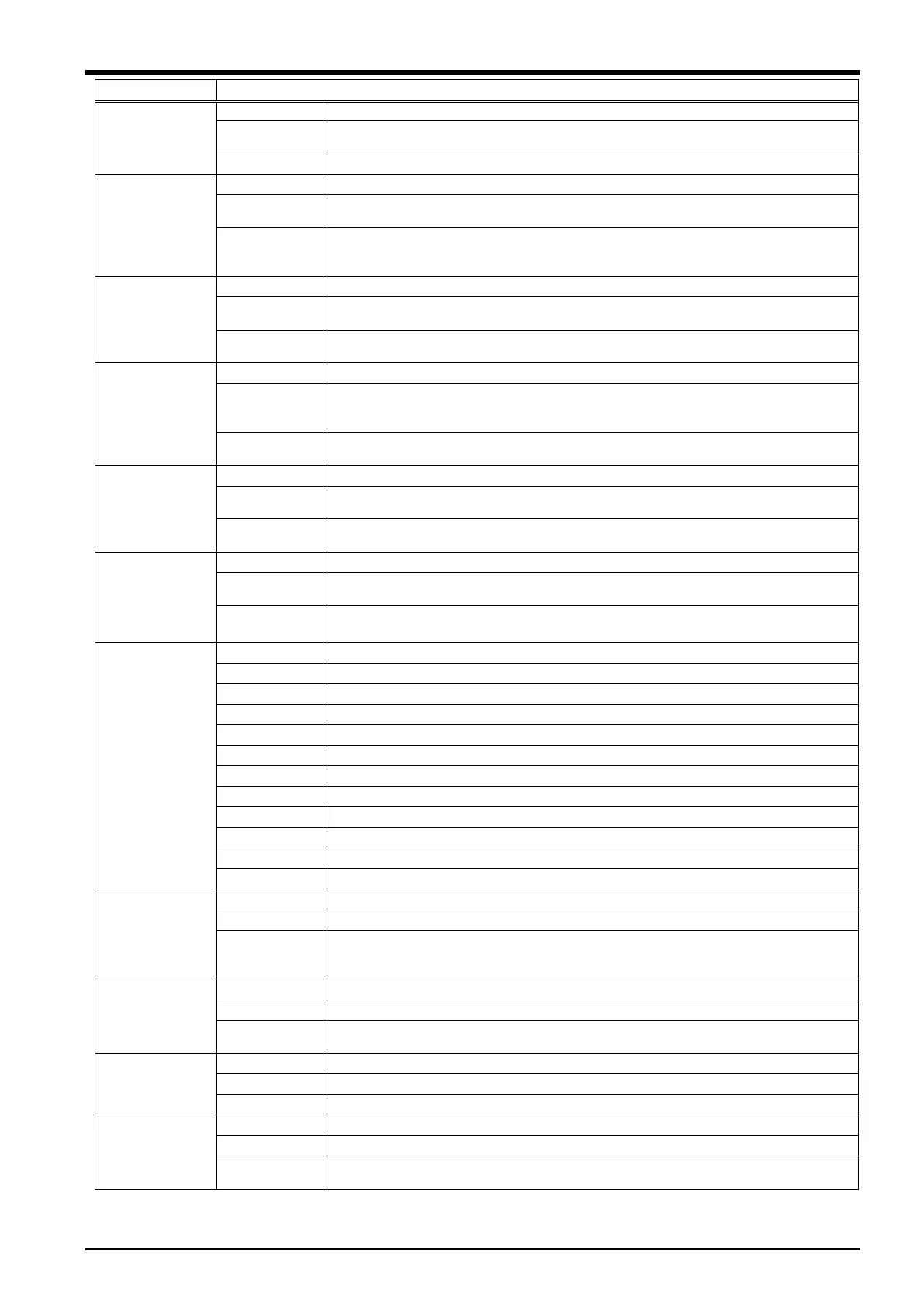

6 TROUBLESHOOTING

6-84 Error List for the Safety Monitoring Functions

Error causes and solutions

H0251 *

Illigal setting of safety IO I/F

Cause

Both safety IO and safety communication are set to valid. Safety IO and safety

communication cannot be used together.

Disable either safety IO or safety communications.

H0252 *

Cause

There is no available module in the slot No. specified in the communication settings

of the safety communication function (CC-Link IE TSN).

Solution

Use the RJ71GN11-T2 with the supported version or later as a network module.

Check and correct the module No. settings for safety parameter communication

settings, then cycle the power.

H0253 *

Cause

The network module specified in the communication settings of the safety

communication function (CC-Link IE TSN) does not support this function.

Solution

Check the network module version.

Use the RJ71GN11-T2 with the supported version or later as a network module.

H0254 *

Safety comm. illegal IP address

Cause

The master station IP address of the communication destination of the safety

communication function (CC-Link IE TSN) does not match the setting value of the

Solution

Check and correct the IP address settings of the master station for safety

parameter communication settings, then cycle the power.

H0255 *

Safety comm. illegal IP address

Cause

The IP address of the host station of the safety communication function (CC-Link IE

TSN) does not match the setting value of the network module.

Solution

Check and correct the IP address settings of the host station for safety parameter

communication settings, then cycle the power.

H0256 *

Safety comm. parameter error

Cause

A communication setting parameter error has occurred in the safety communication

function (CC-Link IE TSN).

Solution

・

Check and correct the IP addresses of the master and host stations.

・

Check that the transmission interval monitoring time satisfies the set conditions.

H220m

(The letter "m" is

a number for a

monitoring plane

or monitoring

area [1 to 8])

SLP (ROBOT position error:CMD Plane)

SLP detected the robot position CMD over the monitoring plane.

Please confirm the robot movement or related parameter setting.

SLP (ROBOT position error:FB Plane)

SLP detected the robot position FB over the monitoring plane.

Please confirm the robot movement or related parameter setting.

SLP (ROBOT position error:CMD Area)

SLP detected the robot position CMD over the monitoring area.

Please confirm the robot movement or related parameter setting.

SLP (ROBOT position error:FB Area)

SLP detected the robot position FB over the monitoring area.

Please confirm the robot movement or related parameter setting.

H2240 *

The origin data is changed during execution of the position monitoring function.

Solution

The origin is set while position monitoring is being executed. This error occurs if the

origin position data is changed while position monitoring is being executed. Cycle

the power of the robot controller, then reset the error.

C2250

Safety function execution disabled (No origin setting)

The safety function cannot be executed because the origin is not set.

Solution

If the origin is not set, the safety monitoring functions will not work. Configure the

origin settings.

H2270

Cannot servo ON (SS1/STO active)

The servo cannot be turned ON while SS1/STO is active.

Disable SS1 before turning the servo ON.

H2280 *

SS1 deceleration time exceeded

The robot didn't stop within deceleration time from SS1 enabled.

Solution

Check operation instructions, terminal load, and stop speed (SFSPZERO)

parameter of the robot.

Loading...

Loading...