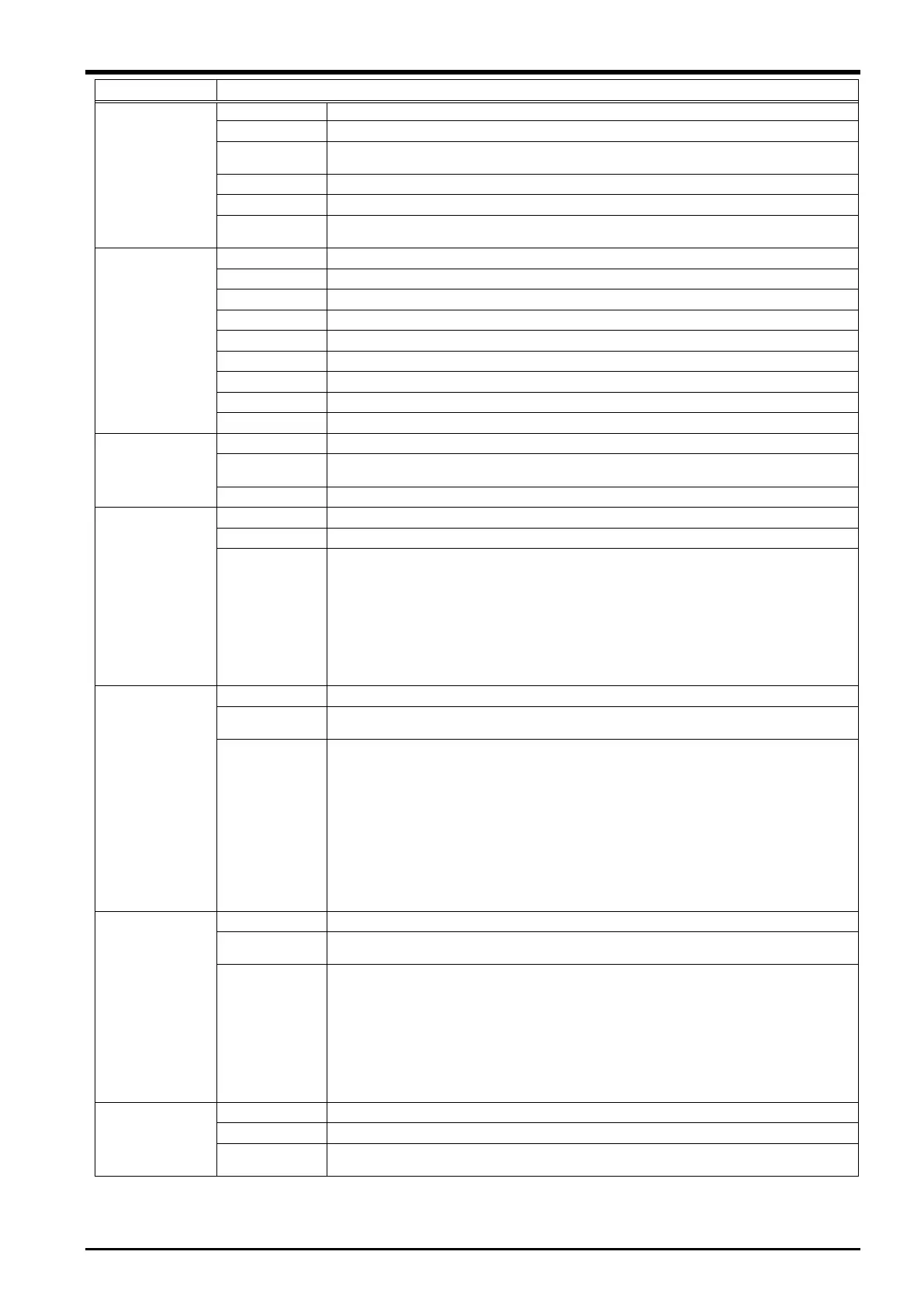

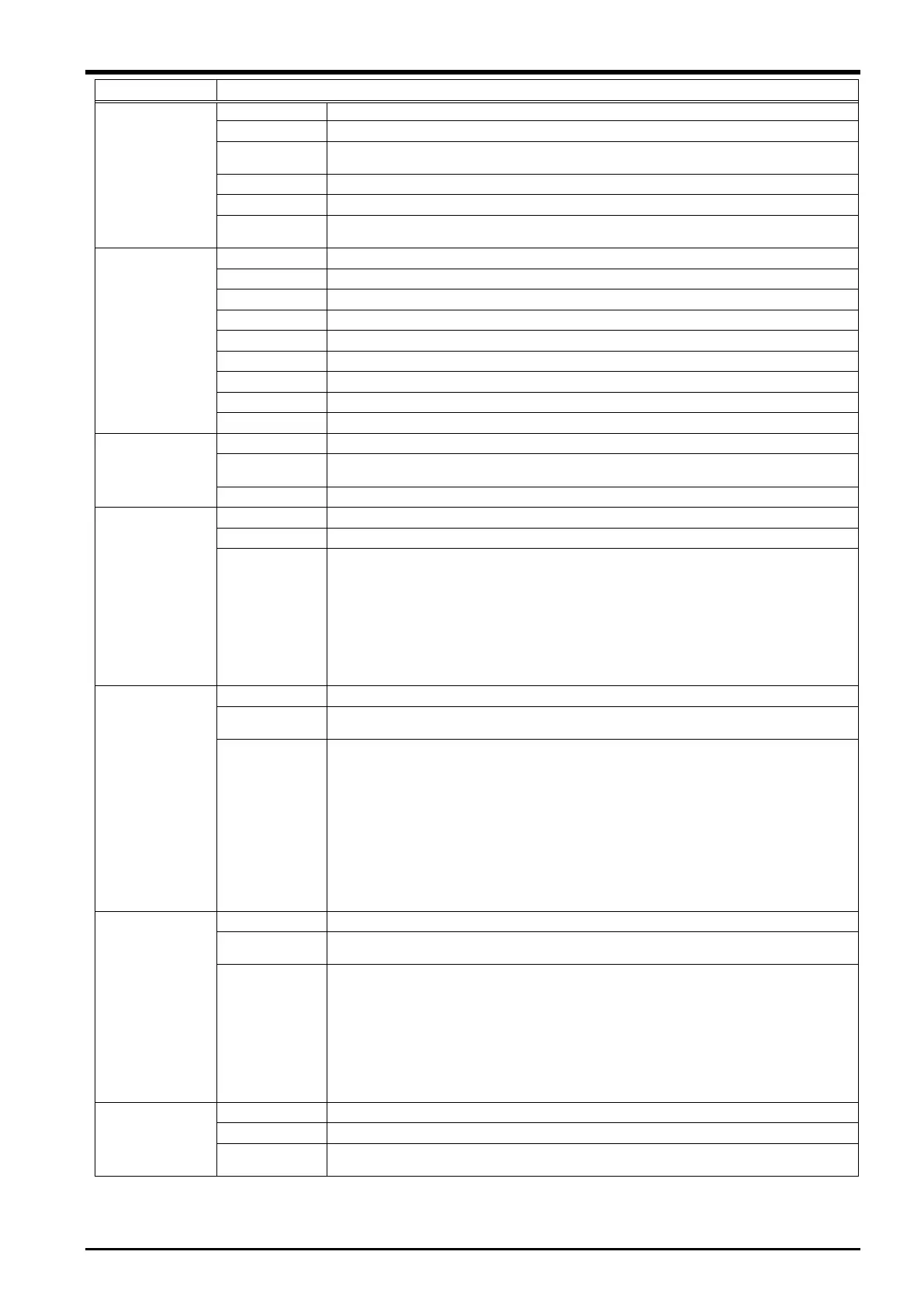

6 TROUBLESHOOTING

6-86 Error List for the Safety Monitoring Functions

Error causes and solutions

H2370 *

The Safety Function is not normally executed.

Solution

Reset the error by power-cycling the robot. If the same error recurs, contact the

manufacturer.

SF (Process Counter error)

The Safety Function of servo CPU is not normally executed.

Solution

Reset the error by power-cycling the robot. If the same error recurs, contact the

manufacturer.

L3880

Invalid SCNI number in M_SCNI

Invalid SCNI number is input in M_SCNI.

Enter any value of 1 to 8.

Invalid LOGIC no. in M_SCNILogic

Invalid LOGIC number is input in M_SCNILogic.

Enter any value of 1 to 3.

Invalid SCNO number in M_SCNO

Invalid SCNO number is input in M_SCNO.

Enter any value of 1 to 4.

H8250

Safety comm. Received error info

Cause

Error information was received from the master station with which the safety

communication function (CC-Link IE TSN) is communicating.

Check the master station error.

H8252

A timeout error occurred in the safety communication function (CC-Link IE TSN).

Solution

・

“

safety refresh monitoring time

”

station is an appropriate value.

・ Check if measures against noise in the transmission path are taken and wiring

and devices have no problems.

・ Check that no online operation is being performed from a peripheral such as the

engineering tool, or no program or parameter is being written to the master station.

・ If the same error occurs again, the possible cause is a hardware failure. Contact

H8253

Cause

A timeout error (unacceptable delay) has occurred in the safety communication

function (CC-Link IE TSN).

Solution

・

“

safety refresh monitoring time

”

station is an appropriate value.

・ Check that the parameter “transmission interval monitoring time” set on the

robot controller is an appropriate value.

・ Check if measures against noise in the transmission path are taken and wiring

and devices have no problems.

・ Check that no online operation is being performed from a peripheral such as the

engineering tool, or no program or parameter is being written to the master station.

・ If the same error occurs again, the possible cause is a hardware failure. Contact

H8254

Cause

A transmission interval error (communication destination) of the safety

communication function (CC-Link IE TSN) has occurred.

Solution

・

“

transmission interval monitoring time

”

master station (communication destination) is an appropriate value.

・ Check if measures against noise in the transmission path are taken and wiring

and devices have no problems.

・ Check that no online operation is being performed from a peripheral such as the

engineering tool, or no program or parameter is being written to the master station.

・ If the same error occurs again, the possible cause is a hardware failure. Contact

H8257

A data error has occurred in the safety communication function (CC-Link IE TSN).

Solution

If the same error occurs again, the possible cause is a hardware failure. Contact

the manufacturer.

Loading...

Loading...