-

37-

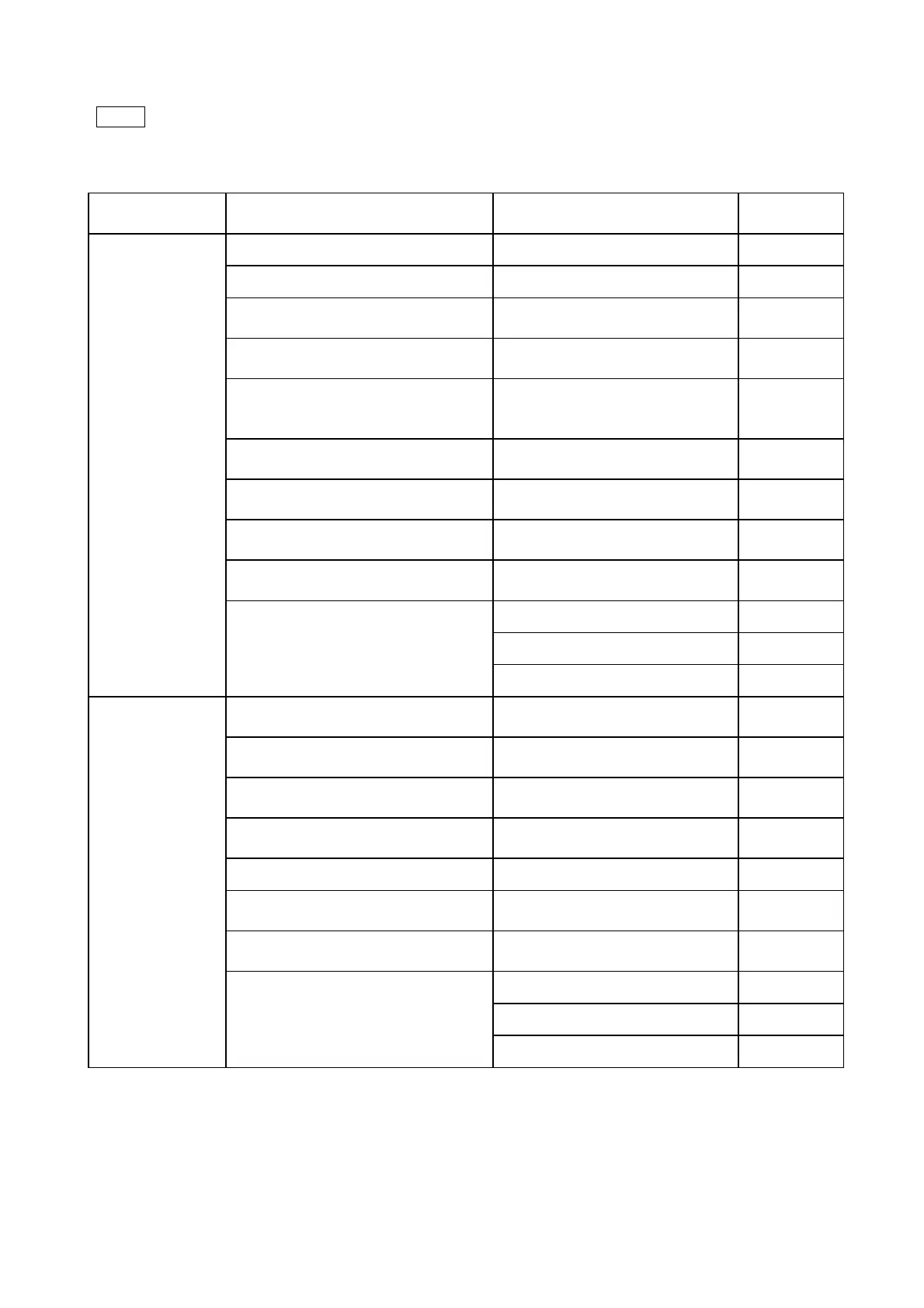

9. BAD SEWING CONDITION & ITS CAUSE AND REMEDY

NOTE

Please fix the troubles during the sewing machine operation with referring to the

following instructions.

Beside, if the trouble conditions are not coming under these classification, please

contact the sewing machine dealers nearby.

Bad condition Cause Remedy

Ref. page

& Item

Poor thread quality Use better quality thread ----

Tight upper thread tension Adjust thread tension 6-3

Strong thread take up spring

Adjust thread take up spring

properly

7-14

Upper thread is thicker than

needle size

Change needle to suitable

size

----

Damages on shuttle hook or

driver

Change them new ones or

grind them with buffing wheel

or grind stone

----

Damages inside needle plate

needle hole

Change it new one or grind it

with buffing wheel

----

Damages inside presser foot

needle hole

Change it new one or grind it

with buffing wheel

----

Needle touches with presser foot

needle hole

Move presser foot position ----

Needle and shuttle hook are not

in proper timing

Adjust the timing ----

Slow down sewing speed 6-2

Use silicon oil ----

1.

Upper thread

breakage often

happens

Thread melts with needle heat

Use needle cooler ----

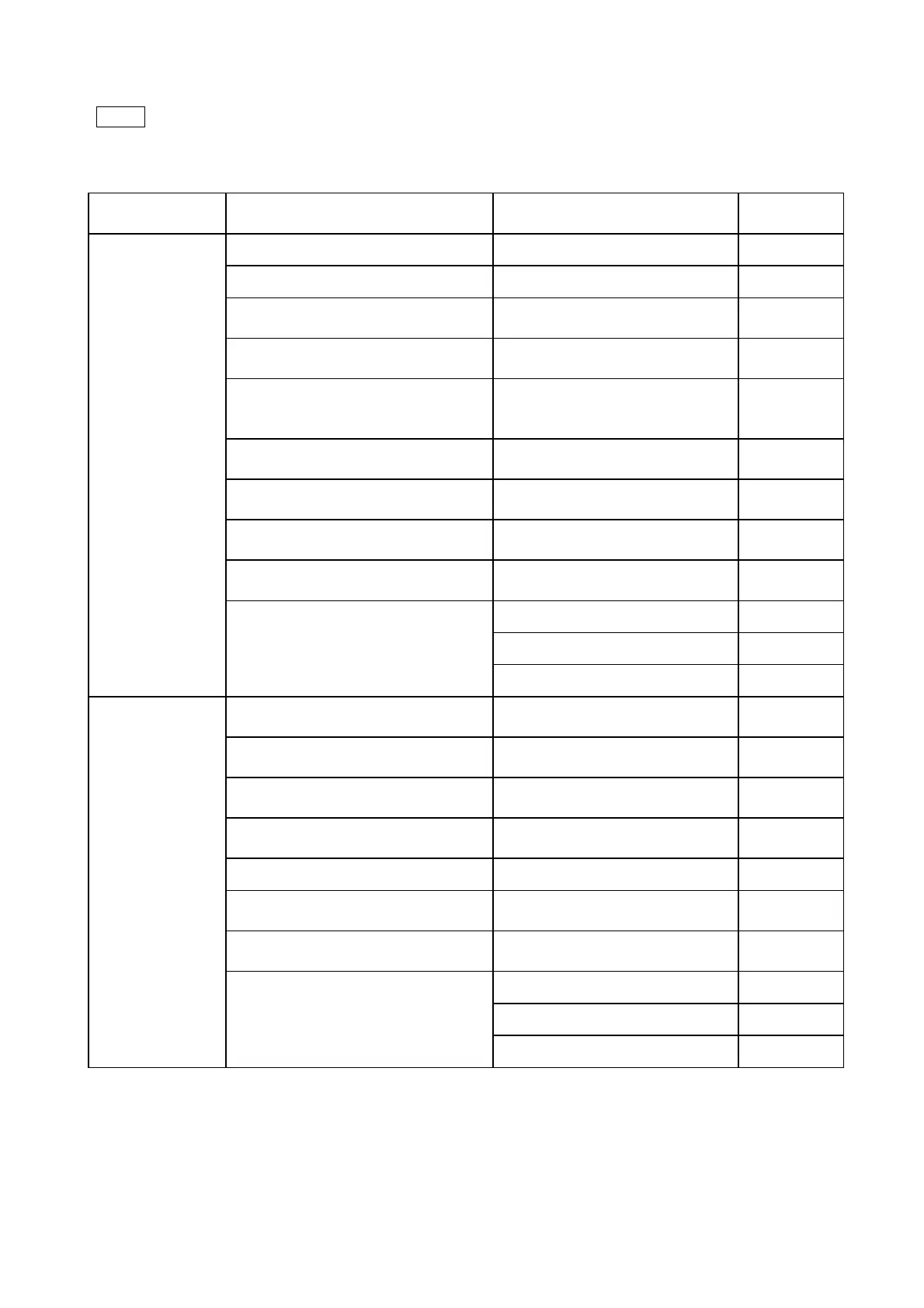

Thread tension discs are not

opened at trimming

Adjust thread tension release 7-17

Thread take up spring swings too

much

Adjust thread take up spring’s

swing stroke

7-13

Upper thread is broken before

regular trimming

Adjust fixed knife and needle

plate position

7-12

Needle size is bigger than thread

size

Change needle to suitable

size

----

Pre-tension is too tight Adjust pre-tension 7-15

Thread guide is in wrong position

Adjust thread guide position

properly

7-5

Needle and shuttle hook are in

bad timing

Adjust the position properly 7-2

Adjust trimmer cam position 7-10

Adjust movable knife position 7-11

2.

Upper thread is

pulled out from

needle

Trimmer timing is not correct

Adjust synchronizer position 7-18

Loading...

Loading...