11

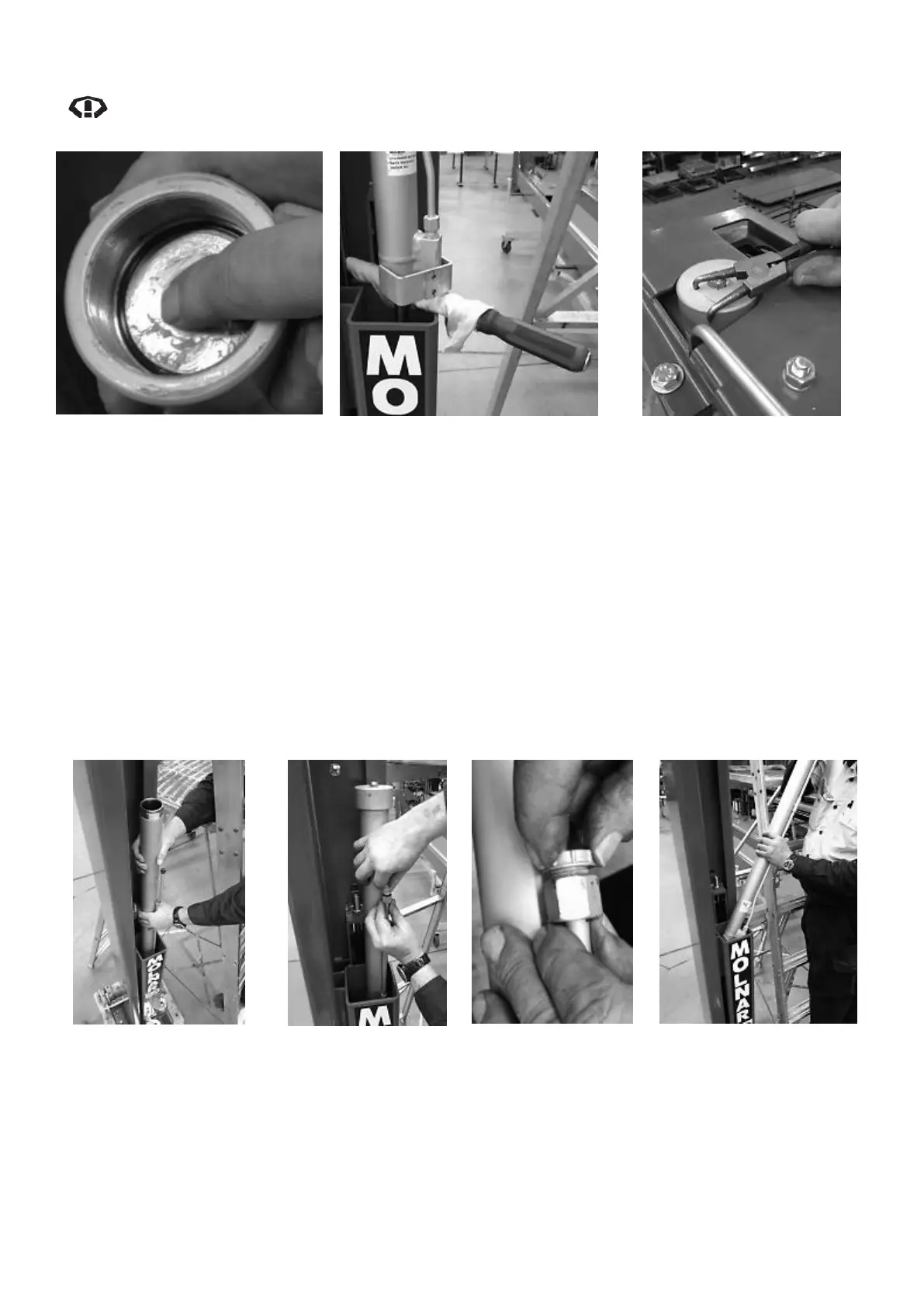

NOTE: When removing or refitting the cylinder end cap, ensure the O-ring is maintained in

position at the top of the thread. Refer to Diagram 8

Diagram 8 – Indication for Cylinder

End Cap O-Ring

Diagram 9 – Bar covered with

Soft Cloth used to support

Cylinder

Diagram 10 – Removing Cylinder

End Cap with Circlip Pliers

7. Place wedge/packers between the top of the carriage and the underside of the cylinder barrel to

support the weight of the cylinder. Wrap the wedge with a soft, clean to protect the cylinder rod from

damage. Refer to Diagram 9

8. Hold the cylinder barrel and unscrew the cylinder end cap; it should only be hand tight but you can

use a pair of circlip pliers to loosen if too tight. Refer to Diagram 10

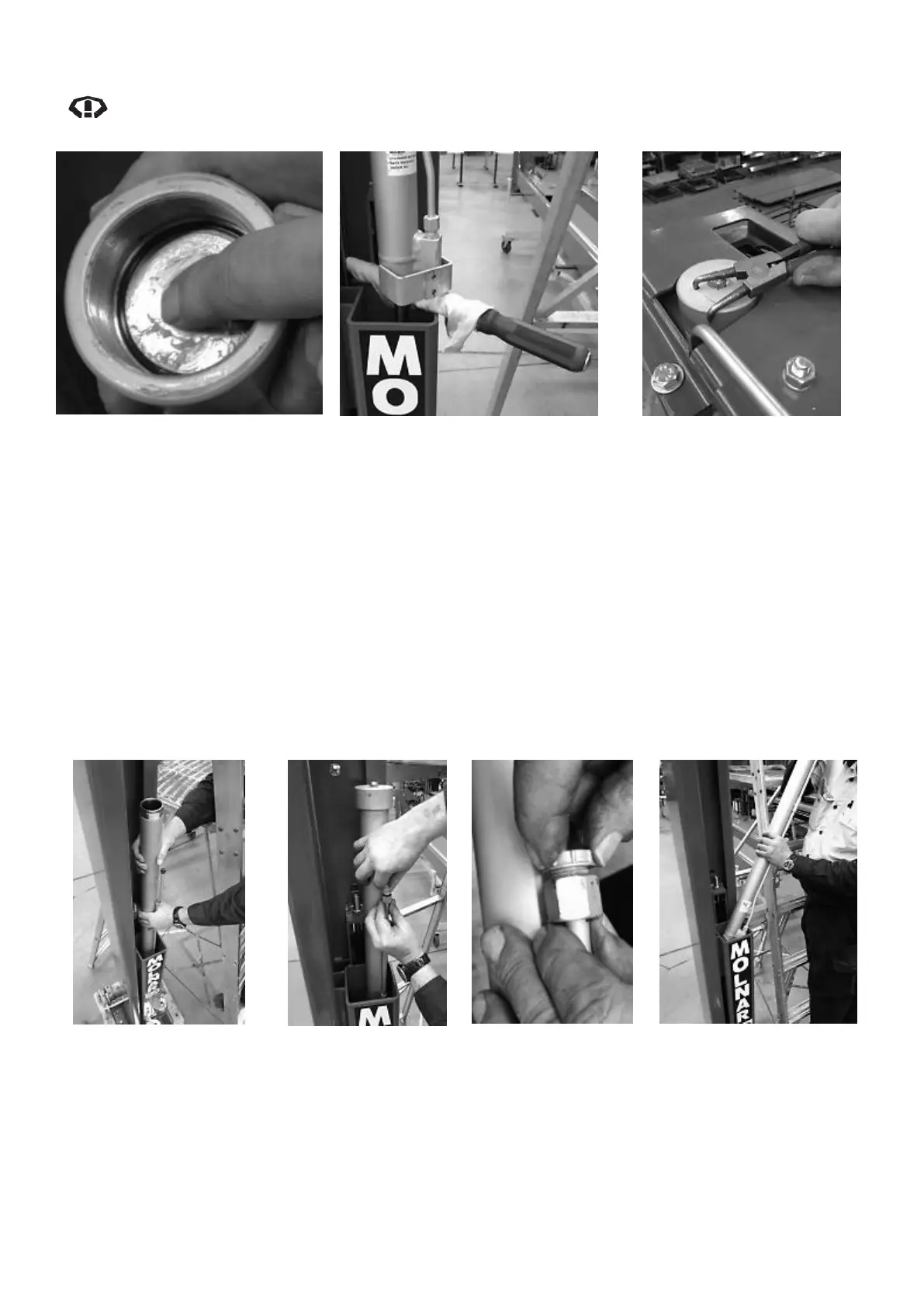

9. While holding the cylinder, remove the wedge/packers and allow it to slide down inside the carriage

until it comes to rest. Refer to Diagram 11

10. Refit (and secure with grub screw) the cylinder end cap and plug the cylinder oil line (use the plug

supplied with the replacement cylinder) to prevent movement of the rod when handling the cylinder.

Refer to Diagrams 12 & 13

11. Lift the cylinder up and out of the carriage. Refer to Diagram 14

Diagram 11 – Lowering

Cylinder down into the

Carriage

Diagram 12 – Cylinder

being Capped &

Plugged.

Diagram 13 – Close-

up image of fitting

plug to hydraulic

fitting.

Diagram 14 – Handling

Cylinder in/out of Carriage

Loading...

Loading...