8

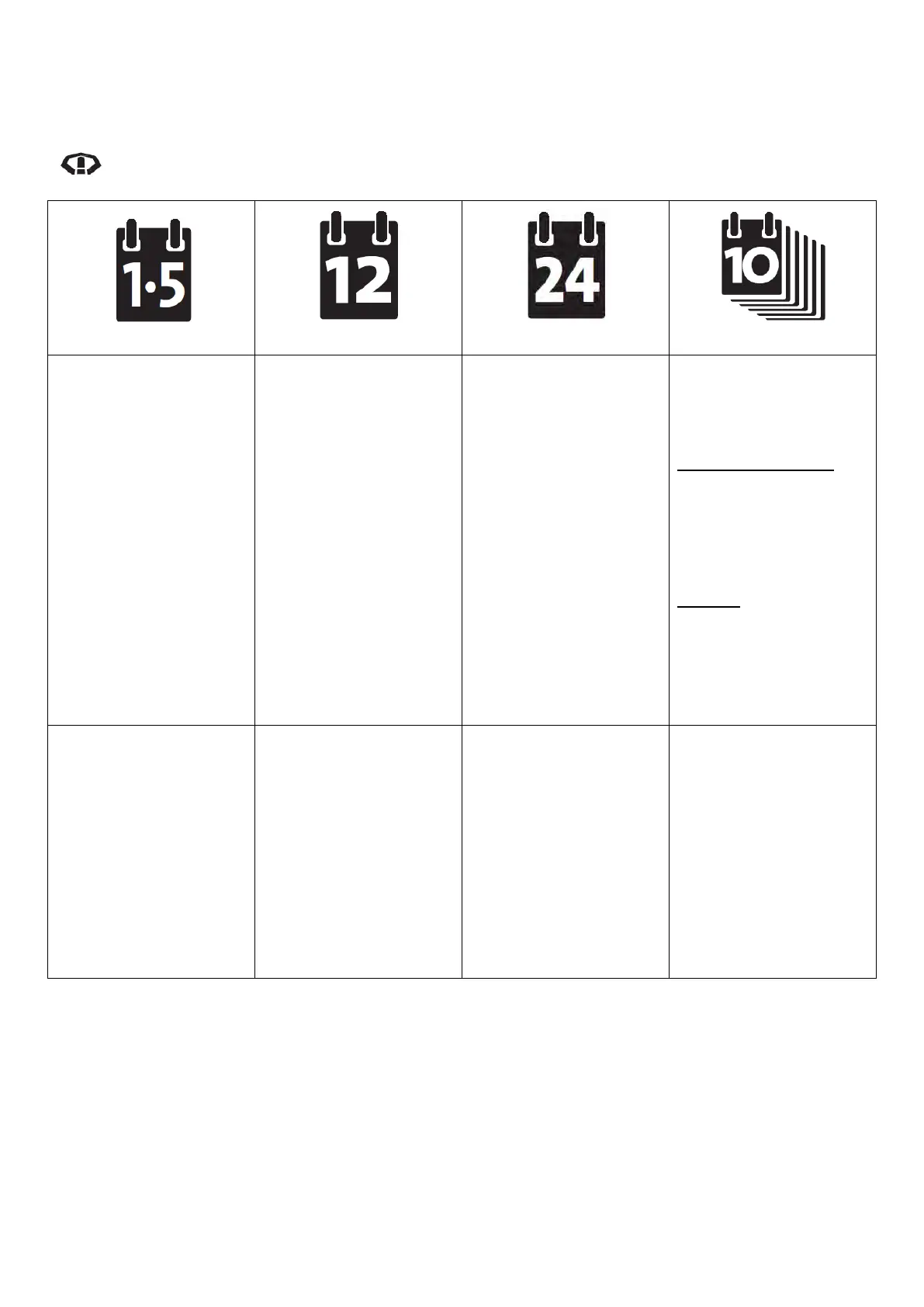

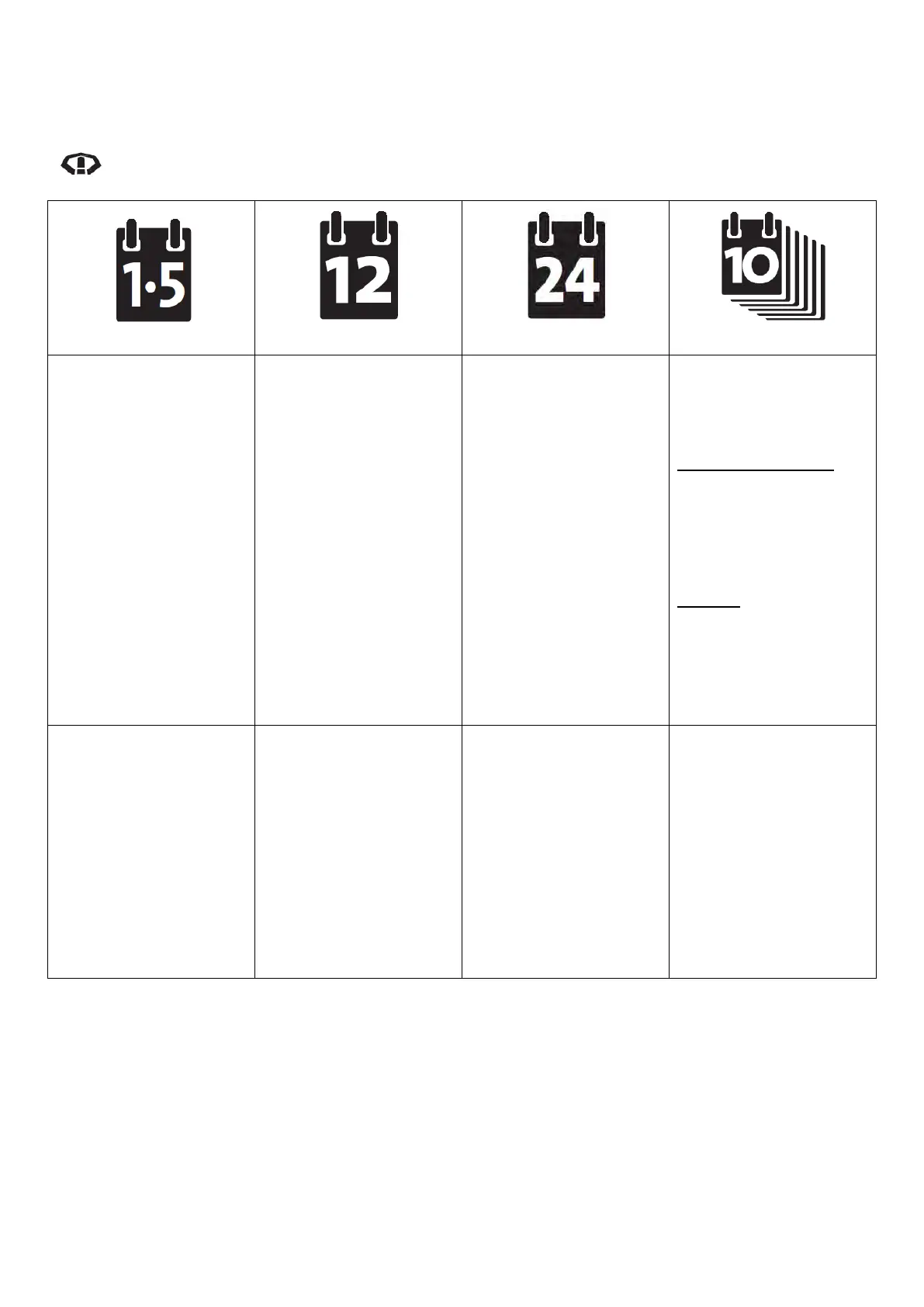

TECHNICIAN MAINTENANCE SCHEDULE (detailed in the Service Manual)

Requirements of the Service Technician to keep the vehicle hoist in safe, good working order and maintain

warranty.

Service and safety inspections on the hoist must be performed by a competent person.

This must be recorded and maintained.

> Replace the

hydraulic oil

> Readjust the balance

cables

> Safety operation test

> Balance cable

inspection,

adjustment and

lubrication

> Lubricate pulleys

> Lifting arms & pivot

pins

> Pick-up pads

> Hydraulic oil and

system

> Electrical controls

and limit switch

> Structural & general

check

> Accessories

condition

In addition to regular

Yearly tasks

> Replace the

hydraulic oil

> Clean tank and filter

In addition to regular

Yearly and 2 Yearly

tasks, a Major

Inspection is required.

Remove and Inspect

> Balance Cables

> Locking Toggles

> Arm Lock

Components

Replace

> Balance cable

pulleys

> Carriage Slide Block

> Pick-up pad rubbers

The first oil change

should occur within the

first 6 weeks of operation

to keep the hydraulic

system in good working

condition.

Although recommended,

this is not mandatory.

If the yearly service and

safety inspection is not

performed, the warranty

is null and void.

To keep the hydraulic

system in good working

condition, oil changes

are required every 2

years or 4,000 cycles.

After 10 years of service,

remove the balance

cables from the hoist,

clean and inspect them

to ascertain

serviceability, replace if

required. If the hoist is in

a high working or

extreme environment,

the balance cables

should be replaced.

Note: Service intervals are based on an average operation of 8 lifts per day, 5 days per week, 50 weeks per

year (2,000 cycles). If operation cycles are more frequent, the service and inspection frequency should

reviewed and set at an appropriate level with your Technician. The intervals shown are the minimum time

periods for inspections.

Loading...

Loading...