14

BALANCE CABLE INSPECTION

Balance Cable Replacement Criteria

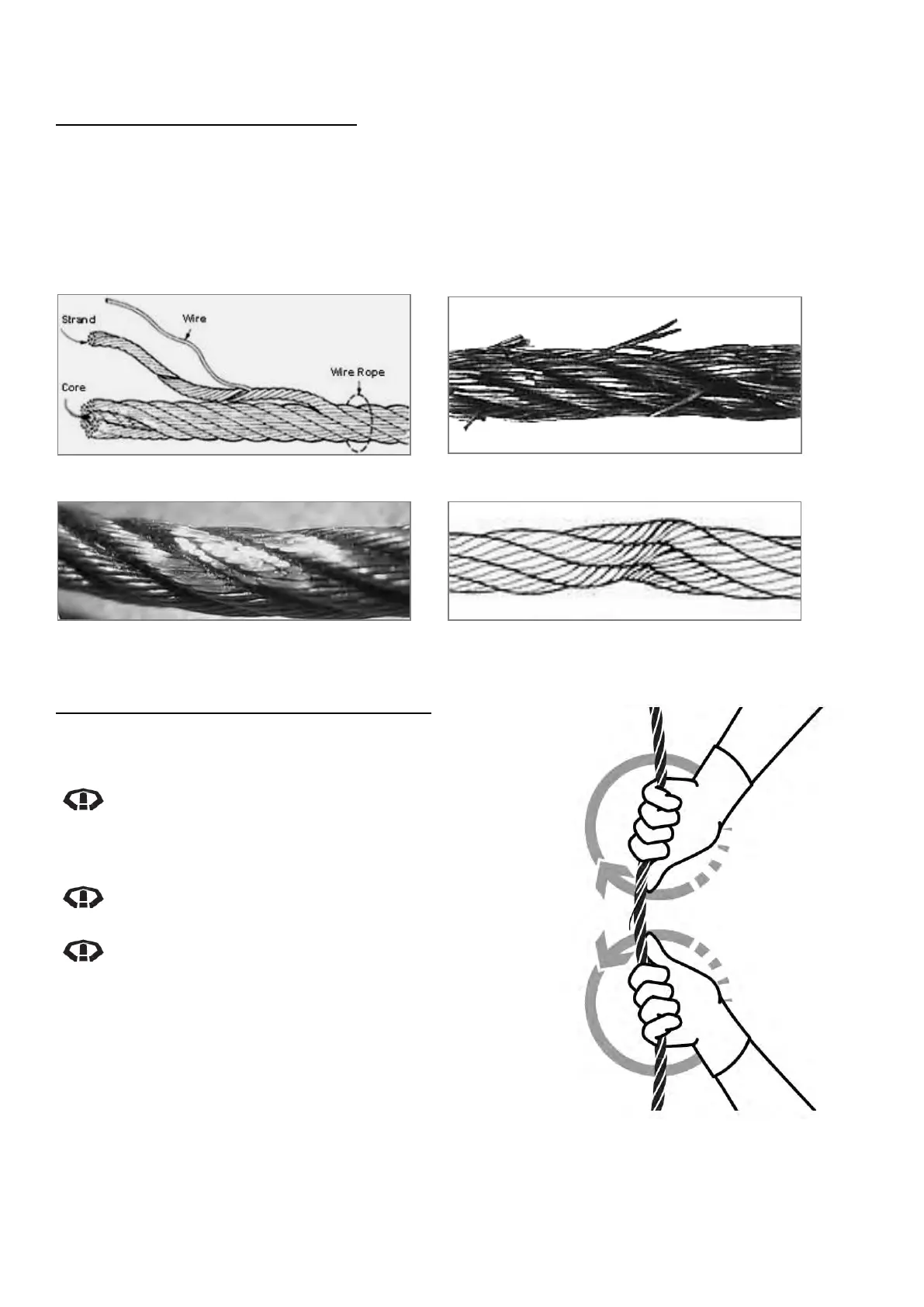

Balance Cables (Wire Ropes) shall be replaced immediately if in any area of the cable;

A. Wire breaks exceed 4 wires within 48mm (Refer to Diagrams 19 & 20),

B. Wire breaks exceed 10wires within 240mm (Refer to Diagrams 19 & 20), or

C. There is break in a single strand (Refer to Diagram 19), or

D. Is severely corroded, worn or damaged (Refer to Diagrams 21 & 22), or

E. Expected to exceed any of the above replacement criteria before the next service.

Diagram 19 – Wire Rope Construction Diagram 20 – Wire Rope Wire Breaks

Diagram 21 – Wire Rope Wear Diagram 22 – Kink or Crush Damage

Balance Cable & Pulley Inspection Procedure

Please make note of the precautions before starting the

inspections.

To inspect the balance cables and pulleys the

tension on the cables must be released to

enable these items to be correctly inspected

and lubricated.

Use gloves when handling Wire Ropes to

avoid injury from broken wires.

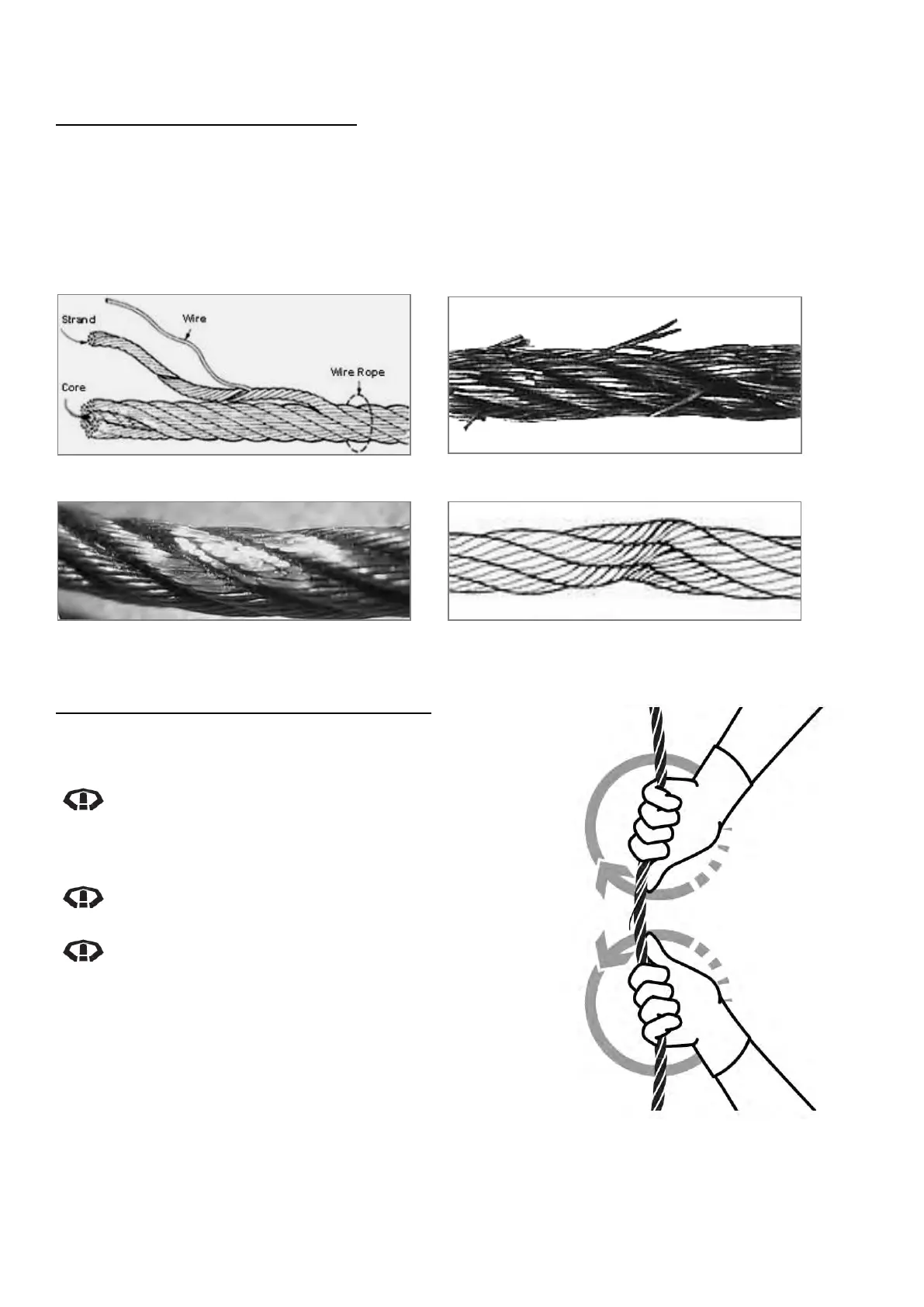

To properly assess wire ropes, you must bend

them to expose any broken wires, refer to

Diagram 23. Give special attention to the

sections that run over the pulleys; check both

the inner and outer running areas of these

sections.

Diagram 23 – Bending Wire Ropes

to Expose Broken Wires

Loading...

Loading...