24

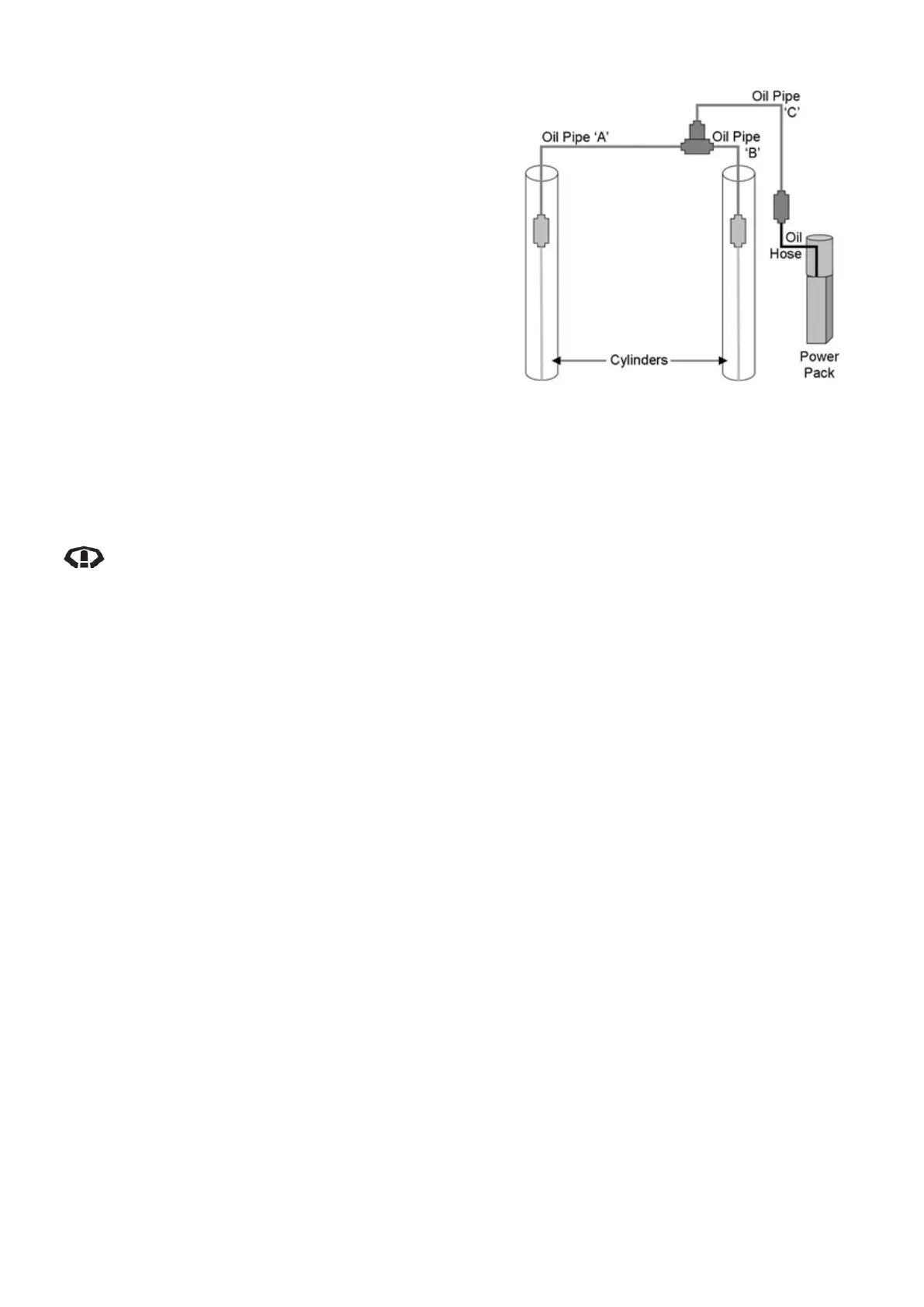

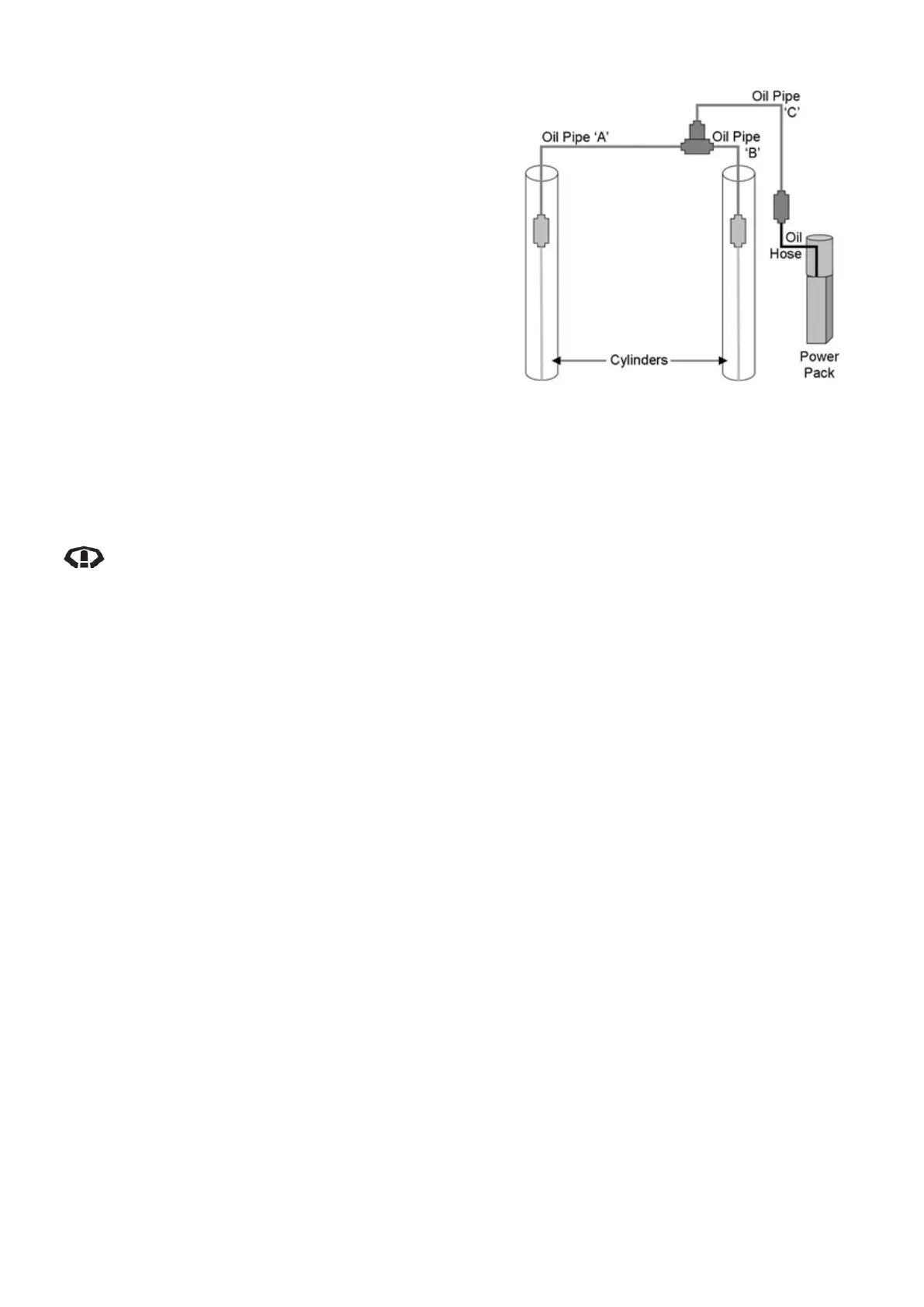

Diagram 39 – Hydraulic Line Layout

displaying location of Fittings

HYDRAULIC SYSTEM CHECK

1. Lower hoist to ground.

2. Check level of hydraulic fluid in tank using dip

stick if an accurate visual determination not

possible.

3. Check all external hydraulic oil pipe connections

for tightness and wipe clean with cloth while

making note of any hydraulic oil found around

fittings or power unit. Refer to Diagram 39

4. Raise hoist to top and lower, locking on first lock

and then remove cylinder covers.

5. Check all hydraulic oil pipe connections and

cylinder for oil leaks. Replace any faulty, leaking

components.

6. Replace cylinder covers and lower hoist to

ground.

REPLACING HYDRAULIC OIL

Hydraulic oil should be replaced every 4,000 cycles or 2 years, whichever comes first.

1. Fully lower hoist to the ground.

2. Isolate hoist from power

3. Unbolt tank from power pack and set on the ground under the pump to catch draining oil.

4. Replace Tank with Drip Tray on the ground under the power pack to catch drip other.

5. Dispose of waste oil as per local regulations.

6. Wipe the inside of the tank clean to remove any sediment and residual dirty oil.

7. Remove filter from inlet pipe of power pack

8. Drain and clean the filter with degreaser then blow out filter with compressed air and wipe dry.

9. Inspect filter and replace if unable to clean effectively.

10. Wipe remaining oil from valve block and pump

11. Refit filter.

12. Refit tank to power pack and fill with new hydraulic oil.

Loading...

Loading...