22

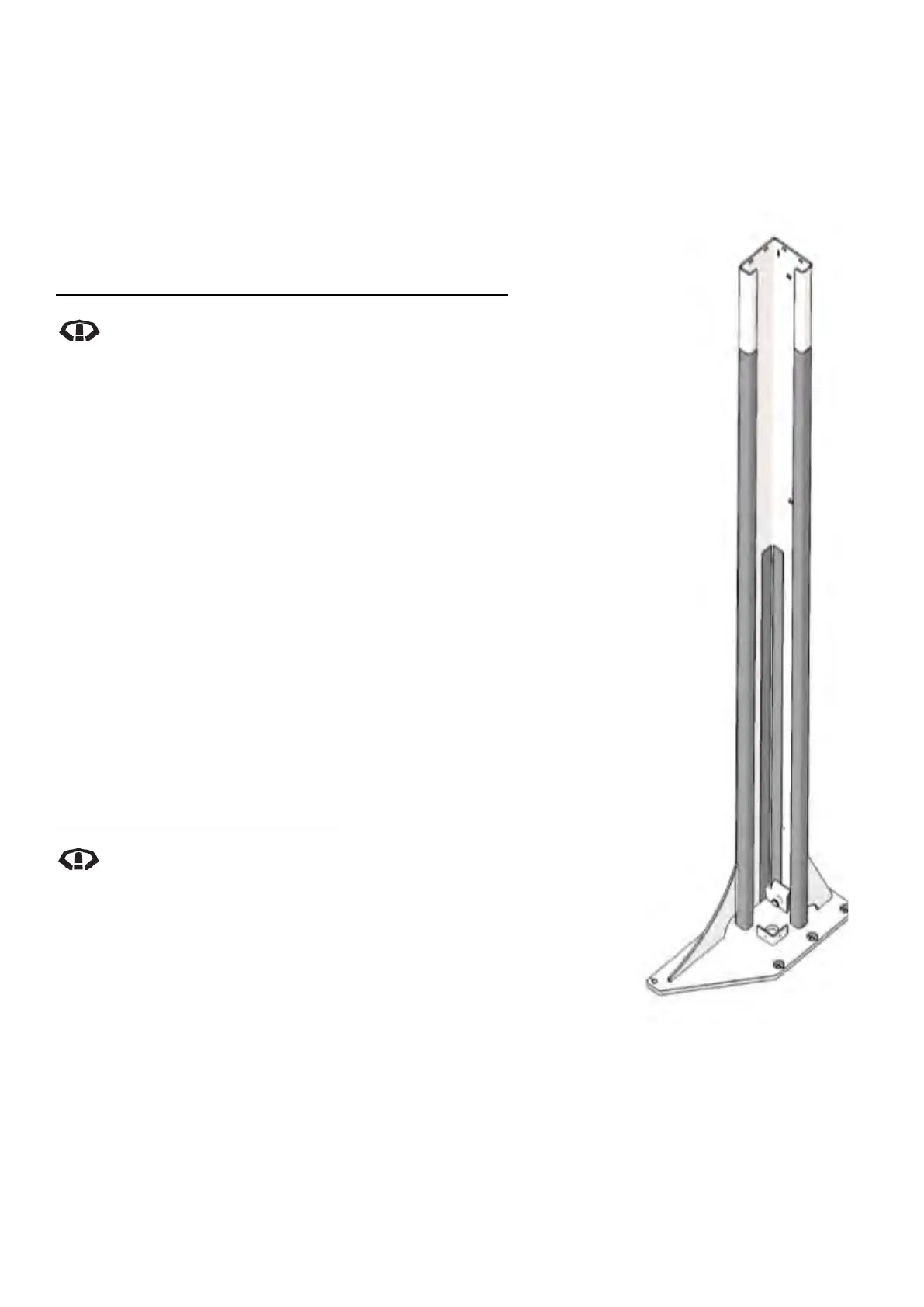

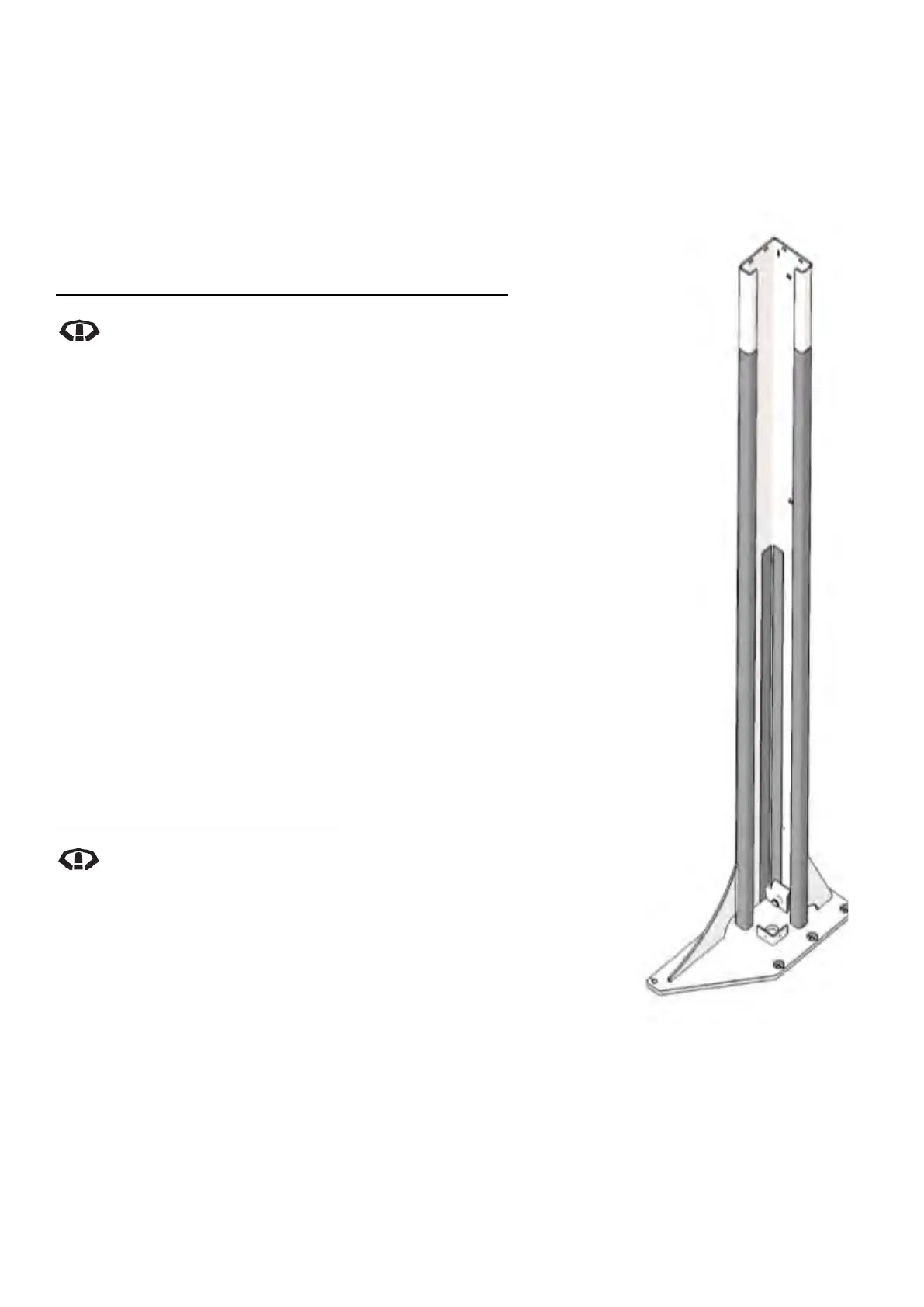

Diagram 38 –

Carriage Slide Block

Lubrication Track Areas

Inside of Post

14. Refit Cylinders, Balance Cables and Lock Release Cable.

15. Reactivate power supply for hoist.

16. Adjust balance cables, lock release cable and bleed hydraulic system.

17. Refit all covers and lower hoist to ground

CARRIAGE SLIDE BLOCKS

Carriage Slide Block Tracks Inspection and Lubrication

When cleaning Carriage Slide Block Tracks, refer Diagram

38, inspect for signs of wearing or scraping inside posts.

Significant long freshly made marks will indicate

requirement to fit new carriage slide blocks.

1. Rock each carriage front to back and side to side inside the post

to check for excessive clearance.

2. Lower hoist to ground remove top cylinder covers

3. Wipe clean the top section of tracks inside the posts and inspect.

4. Apply fresh grease to Carriage Slide Block Tracks in the areas

accessible above carriages.

5. Refit top cylinder covers, raise hoist to top lock and remove

bottom cylinder covers

6. Wipe clean the bottom section of tracks inside the posts and

inspect.

7. Apply fresh grease to Carriage Slide Block track in the areas

accessible below carriages.

8. Refit the bottom cylinder covers.

9. Run hoist through full cycle and remove covers to inspect tracks

grease coverage. Apply more grease in areas if necessary.

10. Lower hoist to ground.

Carriage Slide Block Replacement

When disassembling and reassembling the hydraulic

fittings, first mark an alignment point on both sides of the

fitting. The fitting must be retightened to the same torque

on reassembly to achieve correct seal. Refer to Diagram 3

and the Cylinder Replacement procedure.

1. Remove arms from carriage.

2. Lock hoist on first position

3. Isolate hoist from electrical power.

4. Remove Cylinder and Balance Cables and follow the Top

Balance Cable Pulley Replacement procedure until after the top

plate has been removed.

5. For the Control Post only, disconnect limit switch, disconnect

wiring*, disconnect hydraulic oil lines and remove power pack.

Loading...

Loading...