10

CYLINDER REPLACEMENT

WARNING: The complete cylinder weight is

approximately 20kg, it is recommended to

obtain assistance for cylinder handling.

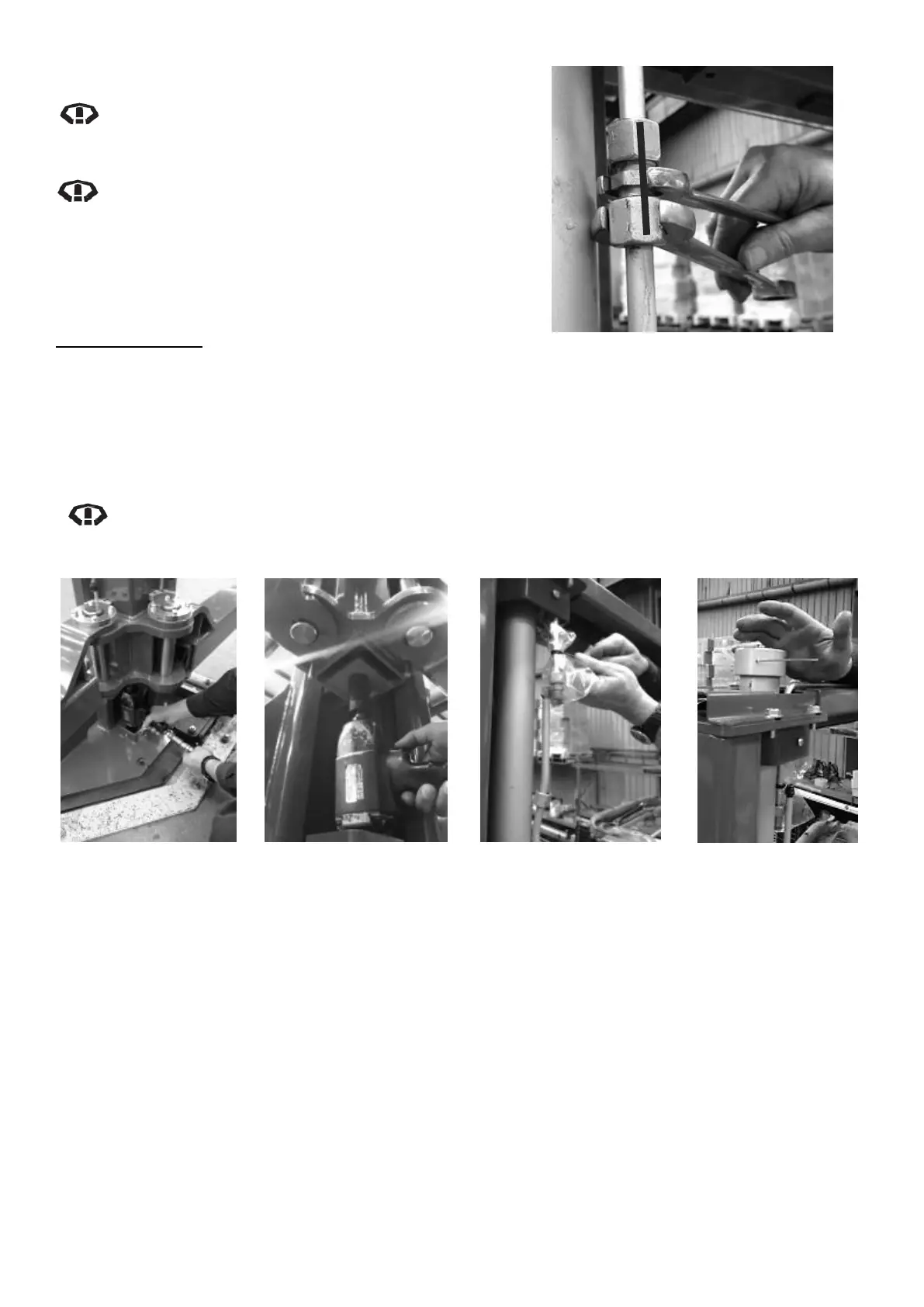

When disassembling and reassembling the

hydraulic fittings, first mark an alignment point

on both sides of the fitting. The fitting must be

retightened to the same torque on reassembly

to achieve correct seal.

Refer to Diagram 3

Cylinder Removal

1. Set hoist on first lock and apply ‘F’ clamp to hold

down the hydraulic release lever to drain oil from

system.

2. Isolate electrical power supply to the hoist.

3. Remove the cylinder covers

NOTE: An impact gun is required to effectively remove or refit the cylinder nyloc nut. For

this purpose, only use the impact gun by applying only in short bursts; short bursts should

only turn the nut and not the cylinder shaft, thus protecting the cylinder from damage.

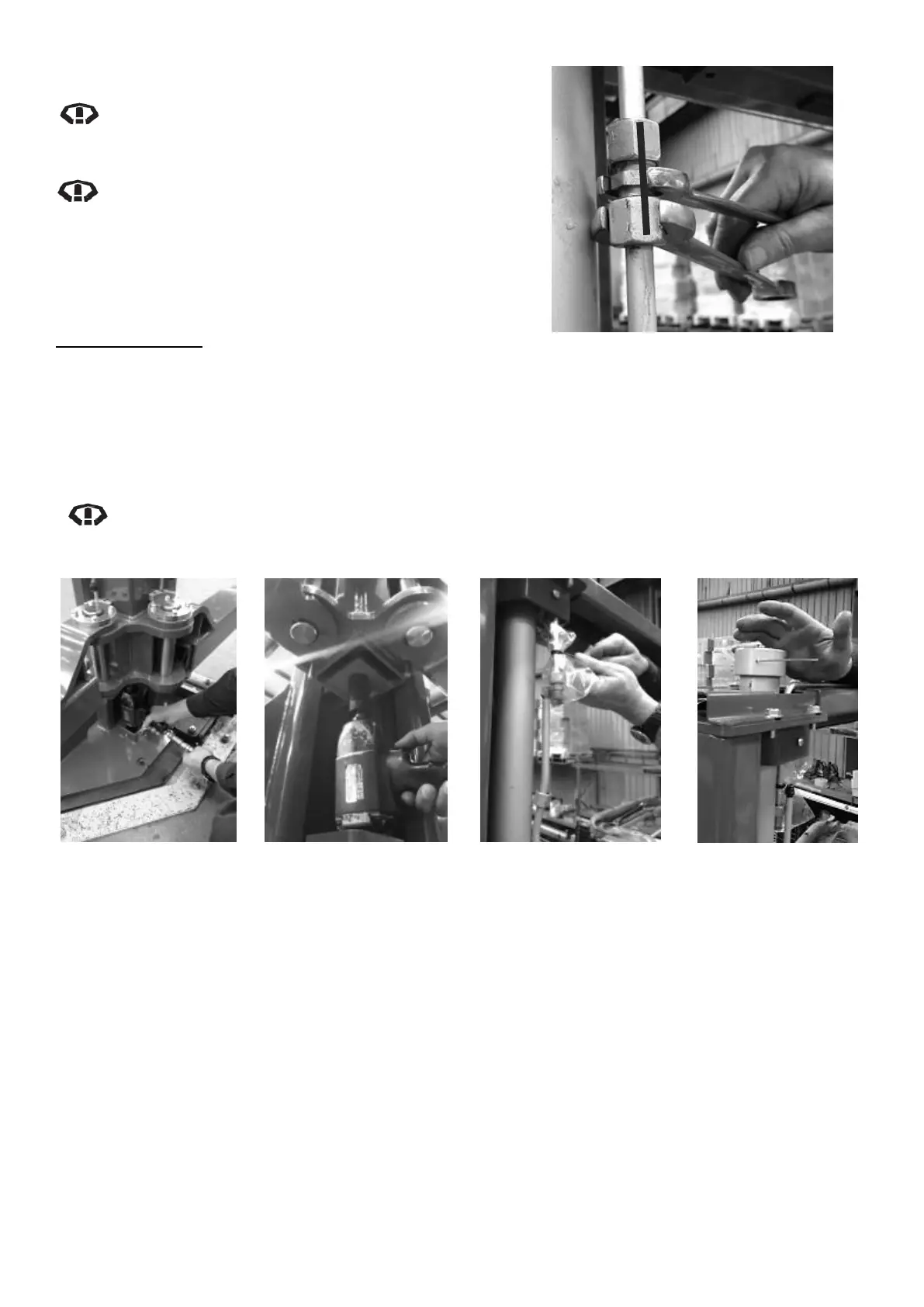

Diagram 4 – Accessing

Nyloc Nut

Diagram 5 – Applying

Short Burst with Impact

Gun

Diagram 6 – Using Bag

and Ties to Contain

Hydraulic Oil Drips

Diagram 7 – Loosening

locking Grub Screw

from Cylinder End Cap

4. Using an impact gun and 27mm socket, remove the nyloc nut from the bottom of the cylinder rod.

Refer to Diagrams 4 & 5

5. Disconnect oil line that connects to the top of the cylinder and secure the end with a small plastic

bag a cable tie over the end of the oil pipe to contain any drips. Refer to Diagram 6

6. With an Allen key, loosen the 2.5mm grub screw (should not require more than 2 turns) in the

cylinder end cap located at the top of the cylinder. Rotate the cylinder to get better access to the

grub screw if required. Refer to Diagram 7

Diagram 3 – Hydraulic Fittings

Reassembly with Position Marking

Loading...

Loading...