ROTARY MOWER

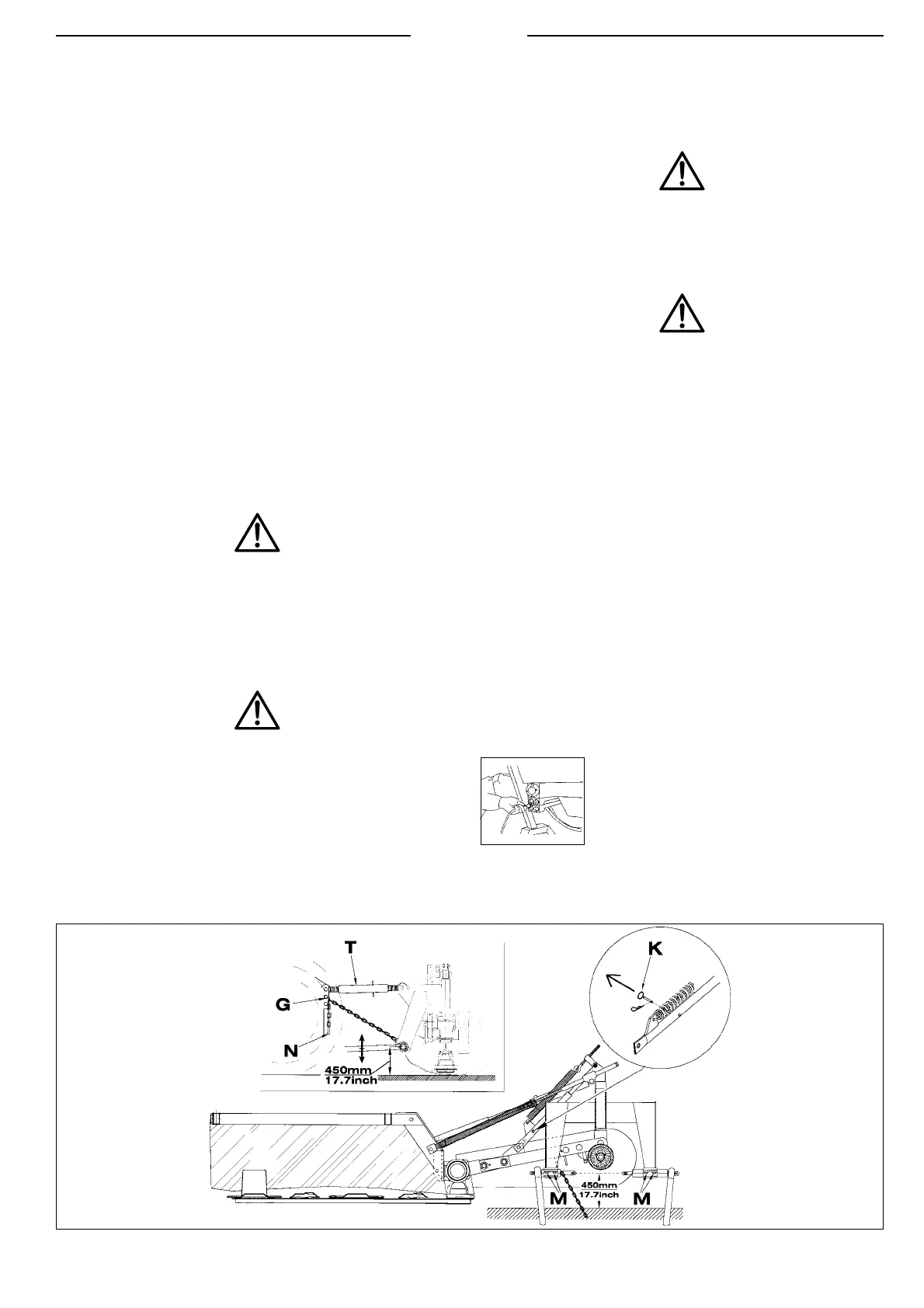

Fig. 6

3.2 COUPLING TO THE TRACTORS 3-POINT

HITCH

The machine can be coupled to all types of tractor equipped

with a universal three-point hitch.

The pins of the 3-point hitch are mobile and can be adjusted

for class 1 and 2.

Ensure that there is sufficient lighting in the work area if the

visibility is poor and have all bystanders move at least 5

meters away from the hitching point.

Move near with the tractor until the power lift bars match the

3-point hitch of the machine, then couple the implement with

the supplied pins.

The two ball ends must be set to the same height from the

ground.

The machine can be adapted to tractors of different track

widths. Make sure that distance L is about 100 150 mm /

3.93 - 5.9 inches (fig. 4).

If the hitch mounting frame needs to be moved, unscrew

the 4 hex screws M on each link (fig. 6) and position the

pins in the correct way.

WARNING

Insert and tighten the safety pins into the pin holes and

make sure that they are well locked.

Connect the upper rod T of the tractor to the top third point

of the tractor and adjust this correctly.

The axis of fork F must be vertical to the ground (fig. 5).

WARNING

Insert and tighten the safety pins. Lock the safety device

that prevents the third point from unscrewing.

Before hitching or unhitching the machine to/from the

tractors third point, make sure that the control lever position

prevents the machine from being accidentally raised or

lowered.

Push bearing stand P upwards and fix it in place with the

pin and split pin (fig. 5).

Lift the machine a few centimeters from the ground and lock

the side movement with the side rods of the power lift bars.

WARNING

Park the tractor on flat ground to prevent the side load

exercised by the machine from bearing on the rods.

3.2.1 HYDRAULIC CONNECTIONS

WARNING

The circuit is under high pressure.

Before beginning any maintenance work on the hydraulic

system, turn off the engine (if it is on), apply the hand brake,

remove the ignition keys from the dashboard and lower the

machine to the ground.

Make sure that all pressure has been relieved from the

tractors hydraulic circuit.

Connect the hydraulic pipes with quick couplings to the

tractor after having checked to make sure that all the fittings

are clean and in an excellent condition.

Inspect the hydraulic pipes regularly and replace any

damaged or worn ones.

These pipes must be replaced by competent technicians in

compliance with the technical instructions given by the

Manufacturer.

CAUTION

Make sure that the hydraulic pipes have

been inserted properly and that their

colour codes have been complied with.

Remember that if they are reversed, the

movements they activate will be in the

opposite direction to the ones controlled

(e.g. lifting-lowering).

Loading...

Loading...