ROTARY MOWER

Fig. 16 Fig. 17

SECTION 5

Maintenance

The recommended routine maintenance criteria illustrated

are based on the Manufacturers experience and advice and

suggestions from the customers.

These criteria are not exhaustive and can be integrated,

also with the collaboration of our customers who we thank

in advance.

Good routine maintenance keeps running costs down and

also allows you to get full use out of all the potential offered

by the machine.

The frequencies given are those indicated by the

Manufacturer for the most usual operating conditions.

Substantially different situations may require the

maintenance work to be carried out more or less frequently,

depending on the specific case in question.

Each new machine must be checked after the first 4 hours

service. Make sure that:

the bolts are tightened correctly;

the tension of all belts is correct;

there are no leaks from any of the components of the

hydraulic circuit;

the transmission components are correctly lubricated.

Periodically and regularly repeat the following inspections

which must also be obligatorily carried out at the beginning

of each season:

check/change the oil, lubricate/grease all necessary points,

as described in the instructions;

check the knives and relative fasteners for wear;

make sure that the knives turn around themselves;

check the protections for wear;

correctly tension the belts;

check to make sure that all bolts are well tightened.

Before beginning work in the field, make sure that the

machine operates correctly and that there are no vibrations.

CAUTION

If faults are discovered, the operator must

immediately stop the PTO, remove the ignition

key from the dashboard, get off the tractor, check

how serious the fault is and then take the

necessary action.

WARNING

The following operations must be carried out before any

servicing work can begin:

- disengage the tractors PTO;

- turn off the tractor engine, apply the hand brake and remove

the ignition key from the dashboard;

- relieve the pressure from the hydraulic circuit;

- always use the appropriate Personal Protective Equipment

(safety footwear, globes, goggles);

- take all the accident preventing measures envisaged for

the type of operation in question.

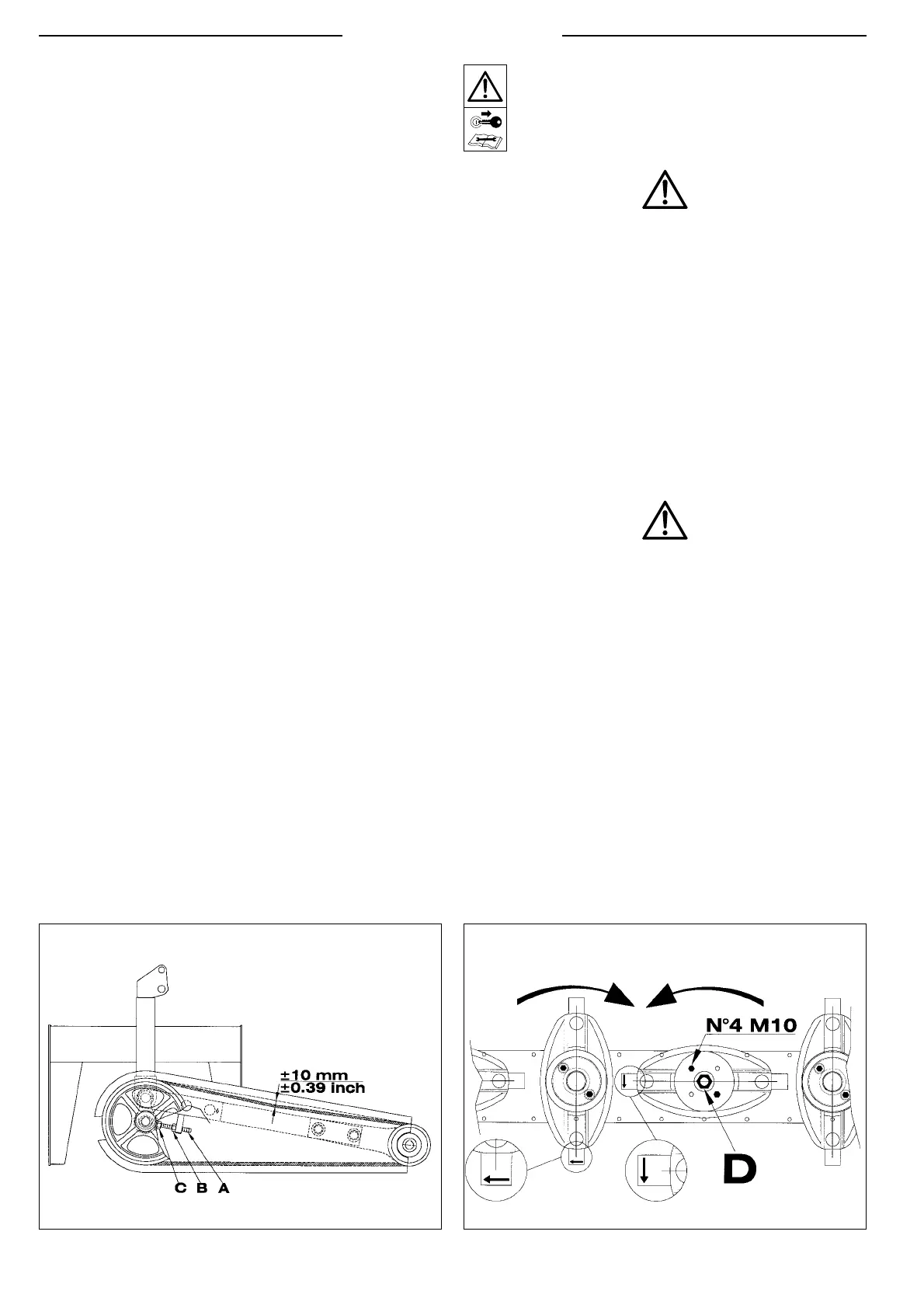

5.1 BELT CONDITIONS

WARNING

The belts gradually wear out and must all be replaced

at the same time.

The belt tension must be checked regularly, particular after

the first few hours of service.

Proceed in the following way (fig.16):

- use idler A and loosen check nut B;

- tighten the belts by screwing head C of idler A until the

belts give no more than 2 cm / 0.78 inches in the central

part.

- lock check nut B and fit the protective casings back in

place.

Loading...

Loading...