ROTARY MOWER

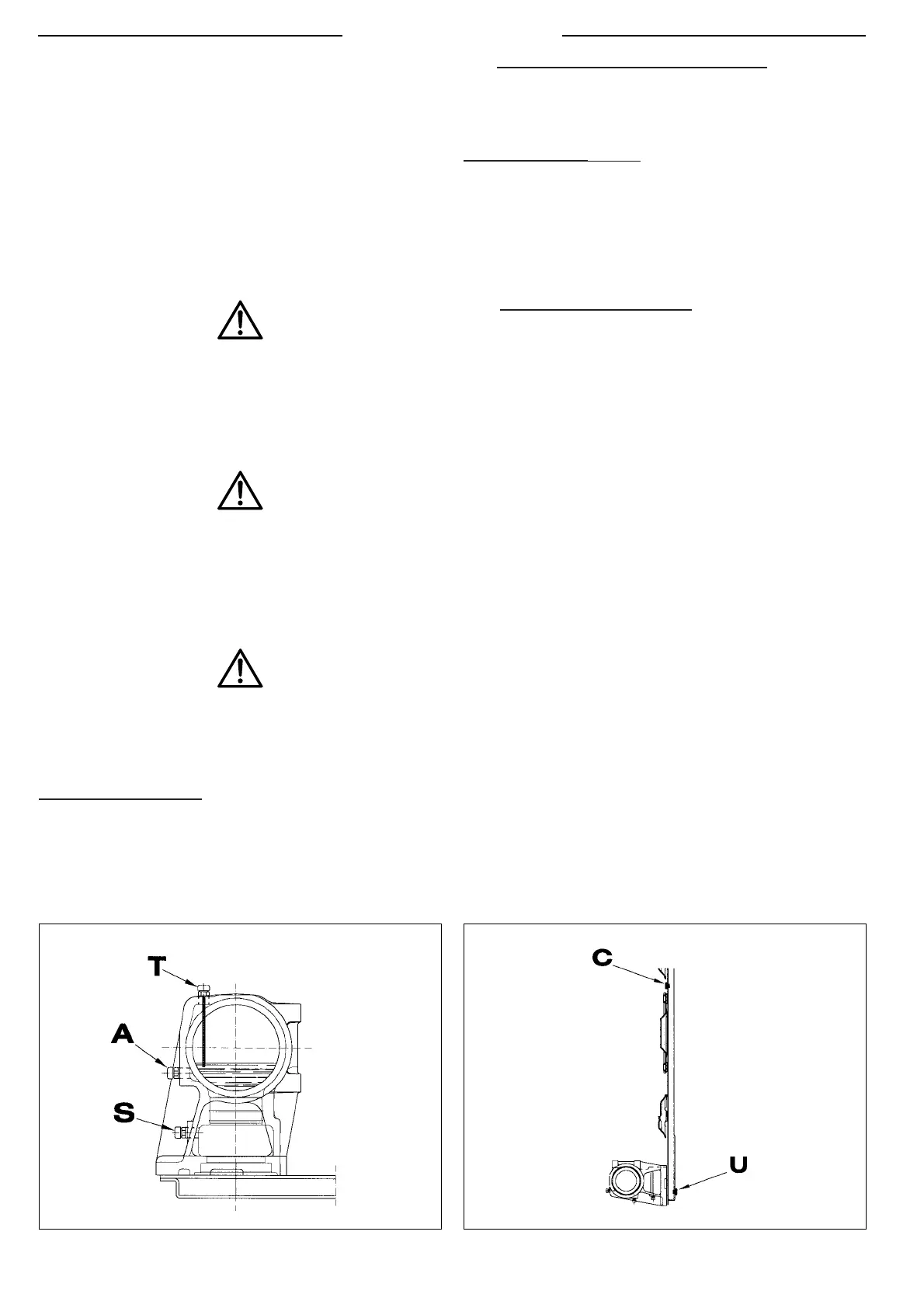

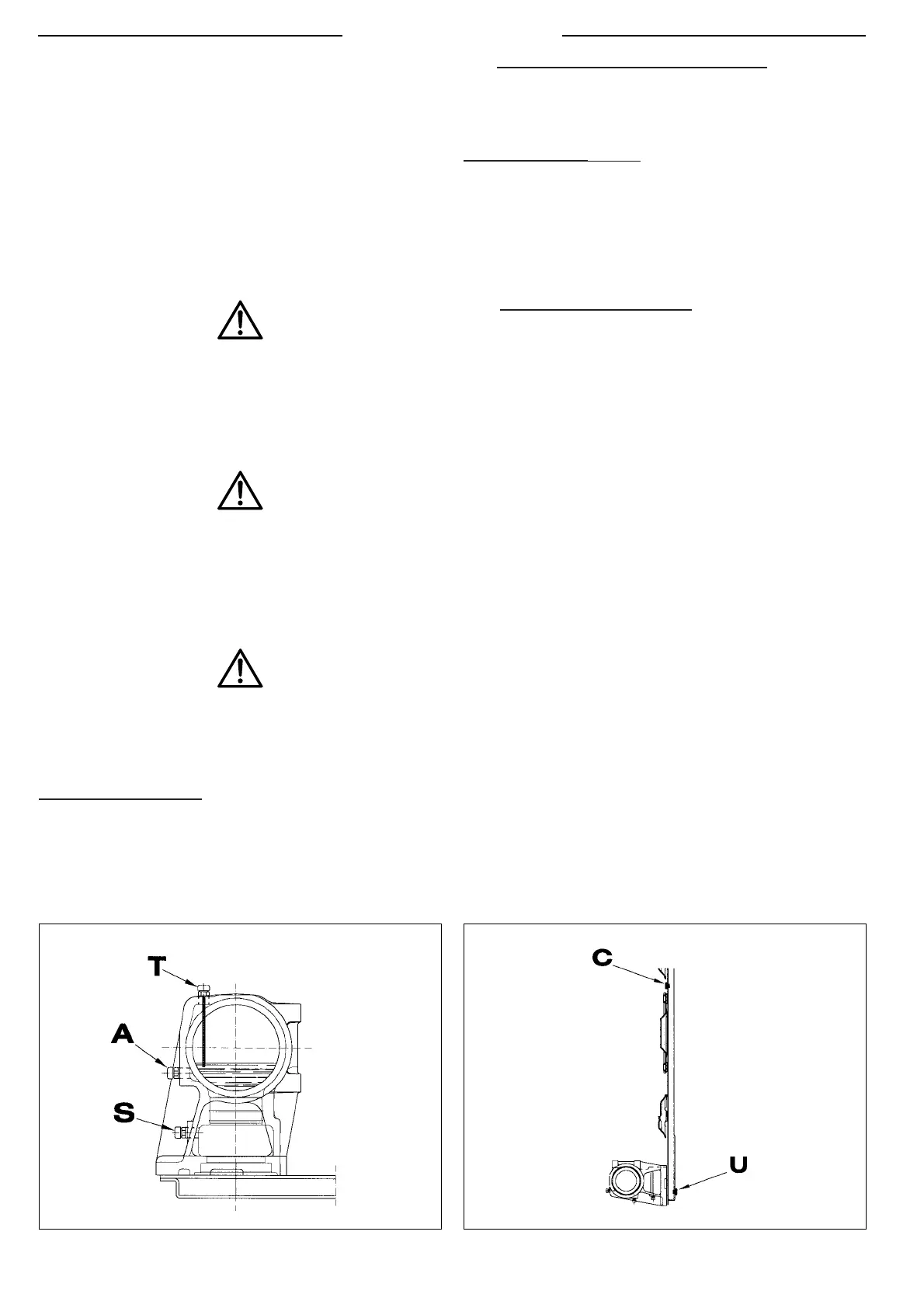

Fig. 27Fig. 26

- the self-braking layer of the fixing screw is missing or

has become too worn (it is advisable to change the screw

after it has been tightened 5 times), (fig.22).

- the fixing screw has become worn in the zone where it

holds the knife: if the diameter is 3 mm / 0.11 inches less

than the original diameter (fig.23).

- the tightening nut is worn: if the height of the nut is 1/2

the original height (fig.24).

- the tightening nut is inefficient: if the washer under the

nut has become flattened (fig.25)

WARNING

The worn or damaged parts must be replaced with ge-

nuine spares.

5.3 HOW TO TOP UP THE LUBRICATING OIL

CAUTION

Change the oil in the unit and bar after the first 10/15

hours service.

After this first change, the oil must be changed after every

200 effective hours service and in any case once a year.

During the period in which the mower is used, check the

level of the oil each day and top it up if necessary.

WARNING

Before proceeding with these inspections, stop the

tractor engine, remove the ignition key from the

dashboard and disengage the driveline transmission.

Overdrive unit (fig.26):

check the level with the relative dipstick on the fill plug (T),

and with the bar in a horizontal position:

T = oil fill plug, with dipstick and breather valve

A = oil drain plug

S = bar breather plug

use: GEAR POWER ISO 150 oil - 0.8 liters

Fill with oil with the bar in a horizontal position (plug T).

Drain the oil out with the bar in a vertical position (plug A).

Mowing bar unit (fig.27):

To check the level of the oil in this component, leave the bar

in a vertical position for 5 minutes to allow the oil to flow

downwards. The oil must reach the level of fill plug C.

C = oil level checking and fill plug

U = drain plug

Use: GEAR POWER ISO 150 oil

bar with 4 discs: 1.7 liters

bar with 5 discs: 2.2 liters

bar with 6 discs: 2.7 liters

bar with 7 discs: 3.2 liters

Fill with oil with the bar vertical (plug C). It should also be

vertical when the oil is drained (plug U).

5.4 HOW TO GREASE THE MECHANICAL

COMPONENTS

Before use and after every 8 hours effective service, you

are advised to grease all the articulations, supports,

hinges, the points equipped with grease nipples and the

safety release (fig.28).

The driveline must also be greased regularly (Fig.28).

Clean and grease the driveline before every long idle period.

The protective tubes must be greased to prevent the plastic

from becoming fragile in winter, when the temperature is

low.

It is advisable to clean mud and other residues from the

tops of the grease nipples before using them to inject

lubricating grease.

Loading...

Loading...