ENGLISH

5.5 STORAGE

- Clean the mower.

- Store the mower in a horizontal position (always lower the

guards and cover).

- Change the oil in the overdrive and mowing bar as indicated

in the instructions (quantity and type of oil).

- It is advisable to slacken off the transmission belts.

5.6 CHECK-CONTROL

TROUBLESHOOTING

* PROBABLE CAUSES

>RECOMMENDED ACTION

The mower vibrates too much during work:

* The nylon bushes of the pivot are excessively worn or

actually missing > replace the bushes;

* The crossbar pivot pin and/or the relative bushings are

excessively worn > replace the worn parts and lubricate

regularly;

* Excessive play on the discs > make sure that the discs

are fixed correctly and that self-locking nut D under the disc

covers is tight, fig.17 (driving torque 18 Kgm = 180 Nm).

The mowing bar (disc carrier) fails to adapt to irregular

ground in the correct way:

* The height of the hitching framework that couples to the

tractor is not regulated correctly > check the setting as

specified in chapters 3.2, 3.5 and 4.1 (in particular: the two

lower pins of the three-point hitch must be equidistant from

the ground);

* The mower pivots are not free to turn > thoroughly clean

and grease all articulations.

The mowing bar fails to lift parallel to the ground (even

when the frame has been adjusted):

* The perforated rod of the bar retracting cylinder is not

regulated correctly > adjust it correctly, by lengthening or

shortening the rod with the relative screws.

Soil builds up between two adjacent skids in the front

part of the bar:

* The soil is too wet > raise the tiller by means of the

tractors power lift in order to lighten the weight of the bar

on the ground.

* The bar weighs down too much on the soil > the springs

are not adjusted correctly;

* The disc bar tilts too much > adjust the bar tilt by means

of the tractors 3rd point idler (see chapter 3.5).

The safety device releases frequently:

* Insufficient pressure exercised by the Belleville washers

> increase the compression of the springs by degrees

(chapter 4.4).

The stubble is too high:

* The disc bar is not slanting correctly > increase the bar

slant by means of the tractors 3rd point idler.

* The ground speed is too high > lower the speed of the

tractor.

The stubble height is uneven throughout the mowing

width:

* The mowing bar slants too much > reduce the degree to

which the bar slants;

* The knives are excessively worn > replace the knives;

* The PTO speed is too low > increase the PTO speed to

540 rpm and no more;

* The ground speed is not correct > increase or decrease

the tractor speed to suit the crop height.

The stubble is too short:

* The disc bar is not slanting correctly > decrease the bar

slant by means of the tractors 3rd point idler.

* The ground speed is too low > increase the speed of the

tractor.

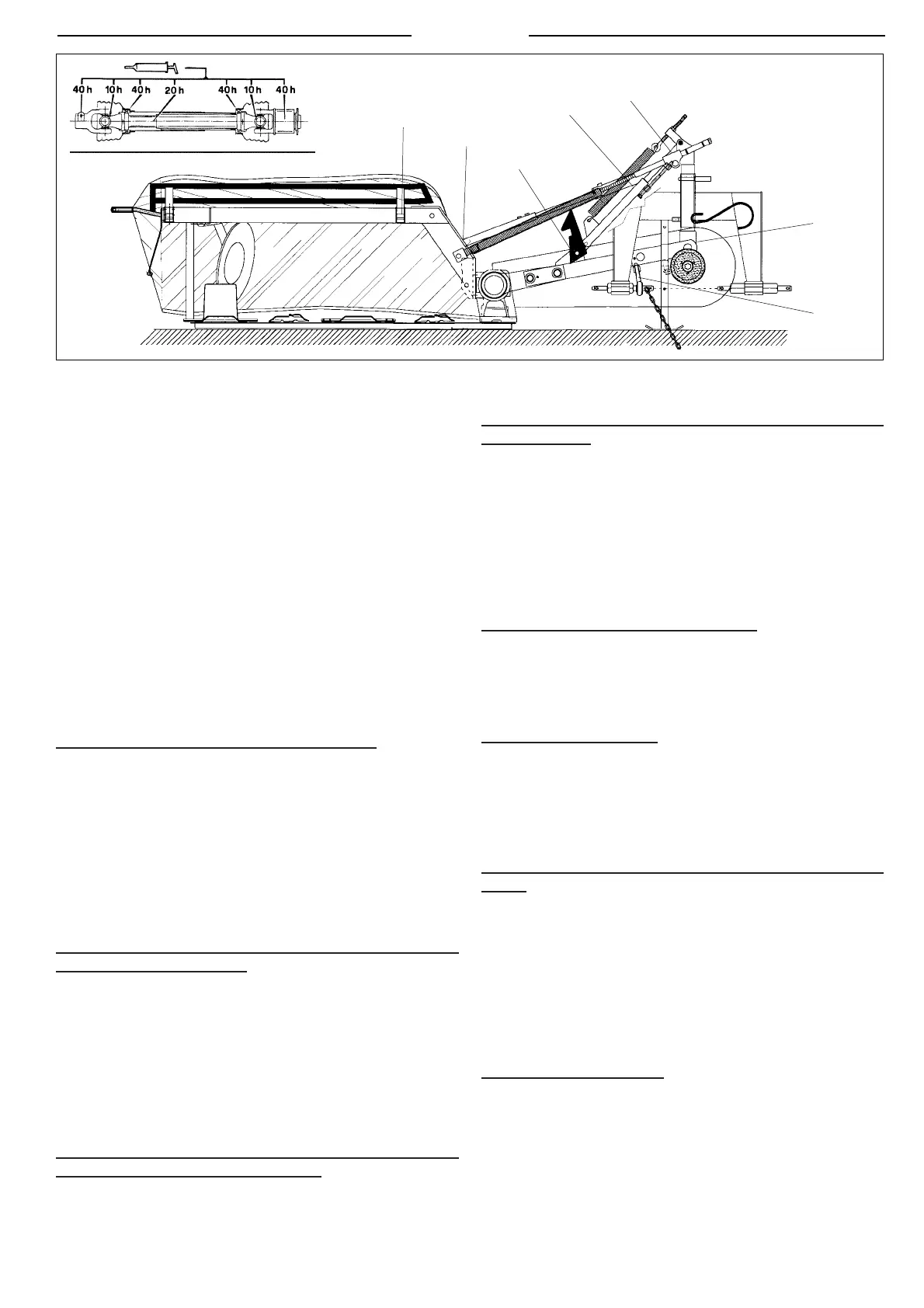

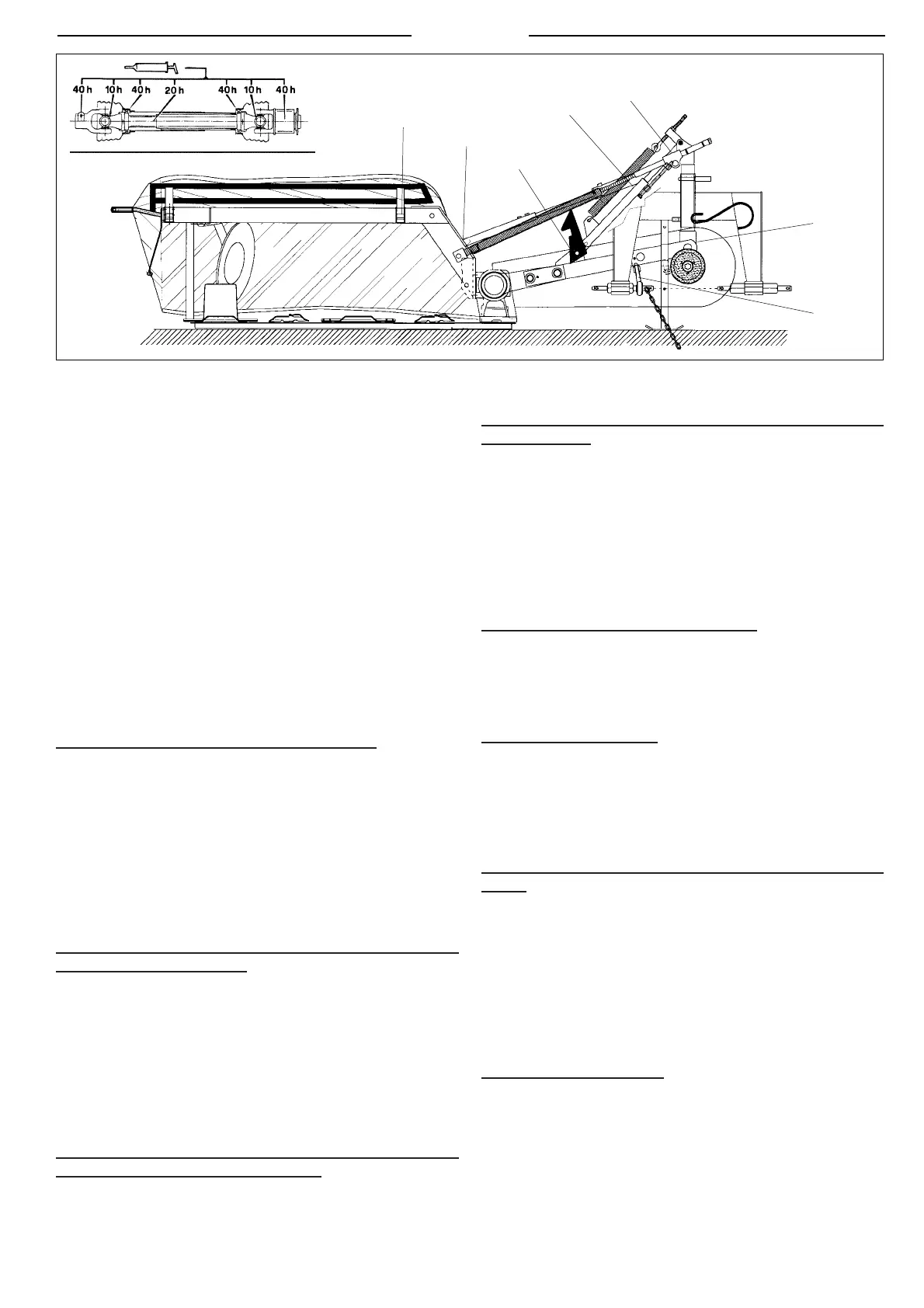

Fig. 28

Loading...

Loading...