Installing injector

1. Remove all covers before installation.

2. Clean sealing surface on cylinder head and

protective sleeve.

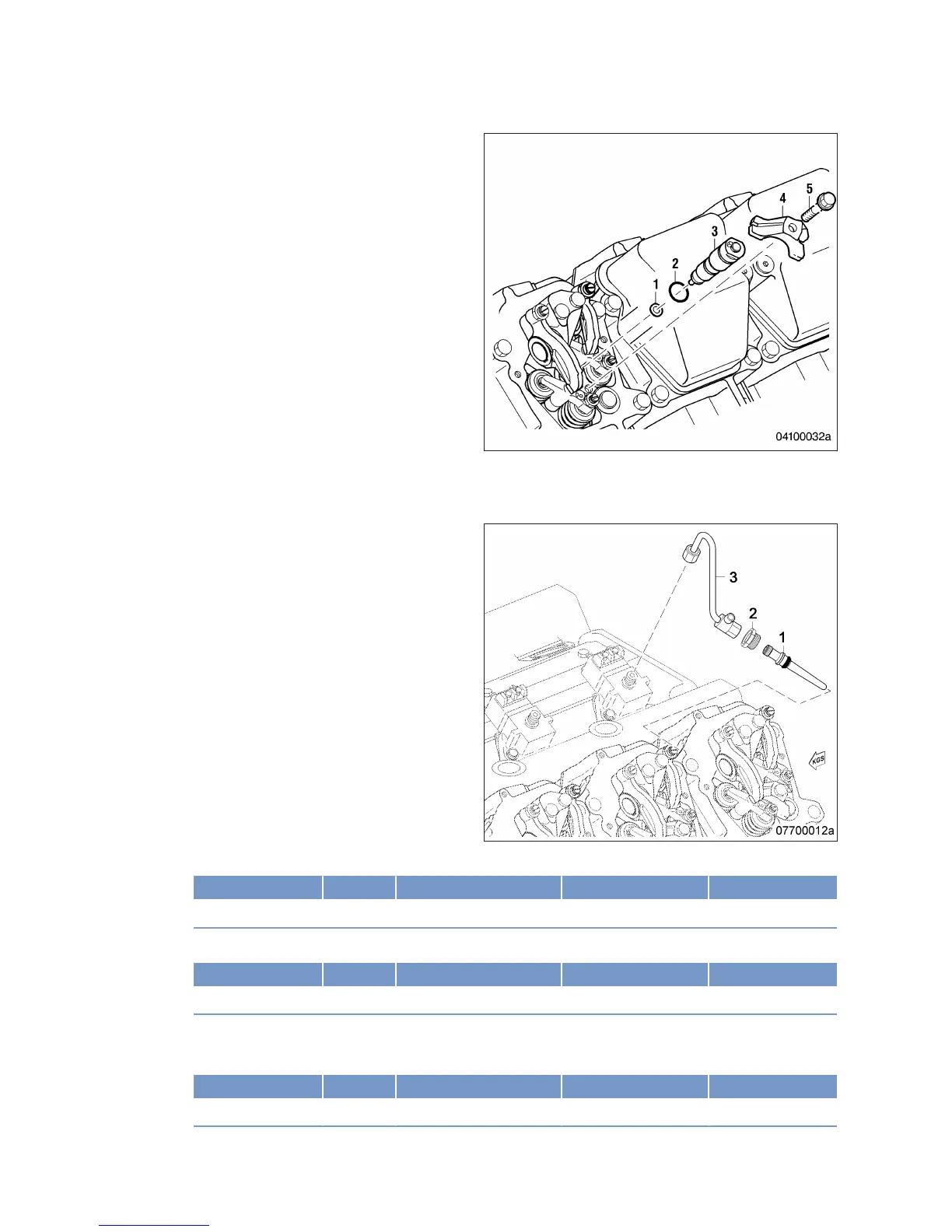

3. Coat sealing ring (1) with grease and fit on‐

to injector.

4. Coat sealing ring (2) with grease and fit on‐

to injector.

5. Press injector into cylinder head by hand.

Result: • The pin is at 11-o'clock position to the

transversal axis of the engine.

• The pin is engaged in the recess of the

clamp (4).

6. Install clamp (4) with screw (5), positioning

it correctly.

Result: • Pin on injector is in the recess in the

clamp.

• Forked clamp end is engaged in the cov‐

er recess.

7. Tighten screw (5) of the clamp by hand.

Result: Injector can still be turned.

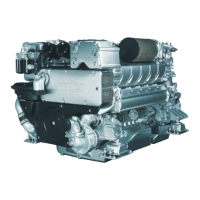

8. Blow out fuel line (3) and pressure pipe

neck (1) with compressed air.

9. Coat sealing ring with grease and fit onto

pressure pipe neck (1).

10. Coat taper on pressure pipe neck with en‐

gine oil.

11. Insert pressure pipe neck into cylinder head

until it is in contact with the sealing ring.

12. Fully press in pressure pipe neck (1) by

hand.

13. Tighten thrust screw (2) with torque wrench to the specified tightening torque.

Name Size Type Lubricant Value/Standard

Thrust screw Tightening torque 40 Nm ±5 Nm

14. Use torque wrench to tighten screw for clamp at injector to the specified tightening torque.

Name Size Type Lubricant Value/Standard

Screw Tightening torque 50 Nm

15. Install fuel line (3).

16. Tighten union nut on the injection pump to the specified tightening torque using a torque wrench.

Name Size Type Lubricant Value/Standard

Union nut Tightening torque 20 Nm +5 Nm

188 | Task Description | MW15550/06E 2012-02

TIM-ID: 0000004646 - 004

Loading...

Loading...