56

5. FEATURES

6. SPECIFICATIONS AND DIMENSIONS

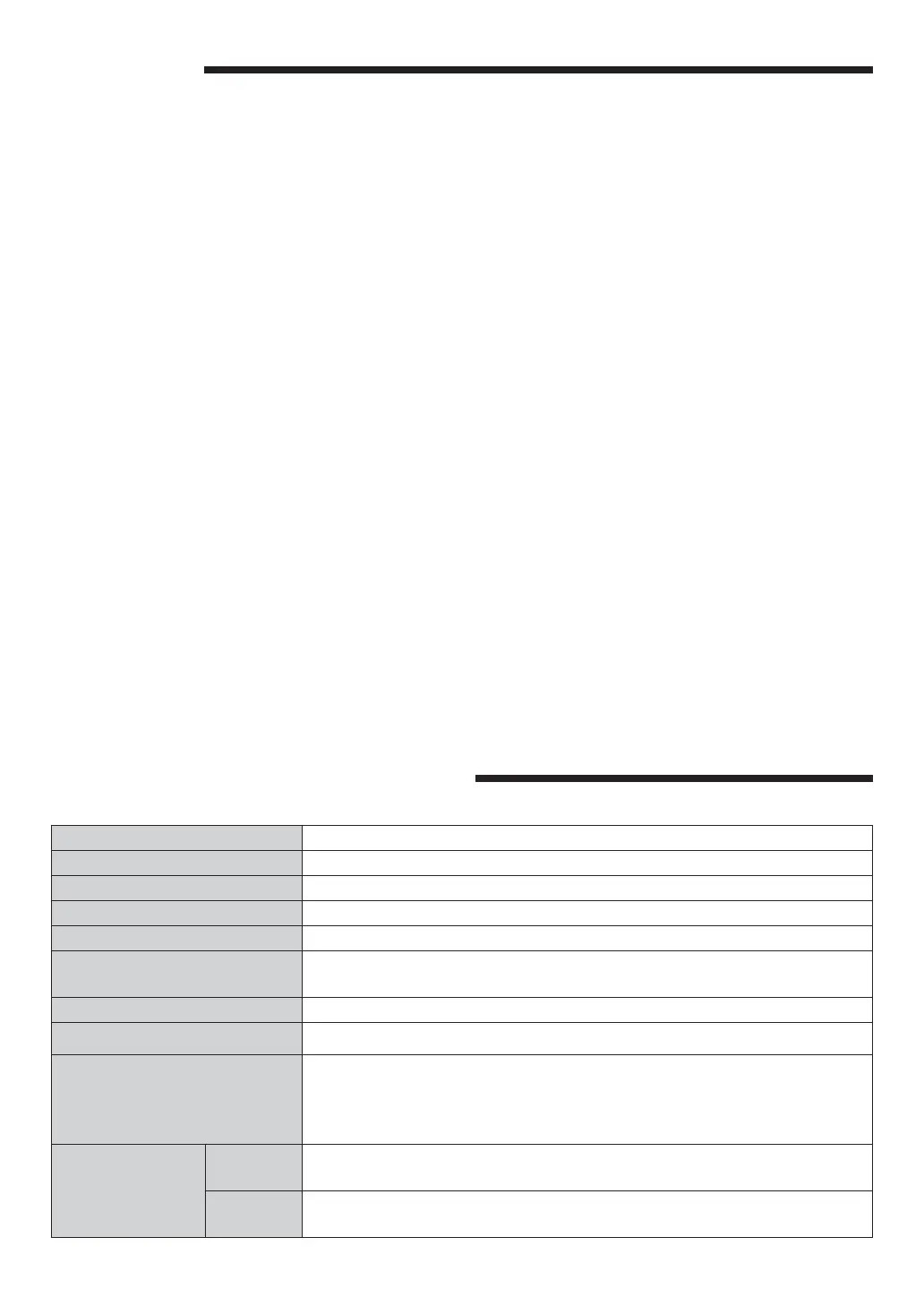

6 - 1 Speci¿cations of CONTROLLER

Product Name E4000 CONTROLLER

Model NE246

Input Voltage AC200 - 240V, 50 / 60Hz, 1 PHASE, 3.2A

Output AC48V, 0 - 0.66KHz, 3 PHASE, 7.8A

Max.Output Power 1,200W (Machine Shaft Output)

Max.Torque

1.0N・m : Motor/Motor Spindle of 20,000min

-1

(rpm) speci¿cation

*1

0.5N・m : Motor/Motor Spindle of 40,000min

-1

(rpm) speci¿cation

*2

Over Voltage Category Ⅱ

Pollution Degree Class 2

Speed Range

1,000 - 20,000min

-1

(rpm) : Motor/Motor Spindle of 20,000min

-1

(rpm)

speci¿cation

*1

1,000 - 40,000min

-1

(rpm) : Motor/Motor Spindle of 40,000min

-1

(rpm)

speci¿cation

*2

External Control

Signal

Input

Signal

Photo Coupler : 9

Analog Connections : 1

Output

Signal

MOS Relay : 8 Photo Coupler 1

Analog : 3 Relay Contact 2 (Safety Relay BOX)

① Although it is a compact unit with a motor / spindle diameter of 40mm, the E4000 system is capable of

outputting high power with a maximum 1,200W, and high torque with a maximum 1.0N・m onto the motor shaft.

②

The E4000 features a high speed type with a maximum speed of 40,000min

-1

(rpm) and a high torque type with

a maximum speed of 20,000min

-1

(rpm) depending on cutting conditions.

③ Speed control and protection functions are incorporated in the high performance microprocessor.

④

A wide speed range, 1,000 - 40,000 min

-1

(rpm) (20,000 min

-1

(rpm)) and settable speed increment of

100min

-1

(rpm) make high precision machining possible.

⑤

Use of an external mechanism such as sequence control allows the E4000 series to be controlled from A CNC / PC

Control. In addition, power output can be monitored v

ia external equipment.

⑥ The CONTROLLER can be placed horizontally or vertically. It can be installed at various places by using the

attached mounting bracket.

⑦ Each operation setting can be set with parameters (memory) that match each user's preferred operating

method.

⑧ Abnormality and malfunctioning status of the CONTROLLER can be checked by error code display by the

Error Detection (warning, error)

of the system.

⑨ An overheat detection sensor is built into the motor, and problems due to abnormal overheating of the motor is

prevented before it damage occurs.

⑩

A straight type and right angle type electric and air connection is available to meet space limitations.

⑪ The motor / spindle housing is made from precision ground, hardened, stainless steel (SUS) with an outside

diameter of ȭ 40mm.

⑫ The mot

or cord is available from 2m to 8m in increments of 2m to meet machine electrical and NSK Control

distances.

⑬ The control panel is removable. It can be installed on the rear of the CONTROLLER, allowing for Àexibility of

operation.

⑭

The Control Panel can be installed at a distance of 4m from the CONTROLLER body by using an optional E4000

Control Panel Extension Cord.

⑮

In an Emergency Stop condition, the power to the motor can be securely disconnected via a relay by using

the E4000 Safety Relay Box. A safety system between the E4000 CONTROLLER and the machine can be

con¿gured by utilizing auxiliary contacts.

Loading...

Loading...