7

© by NECTA VENDING SOLUTIONS SpA 0407 239 - 00

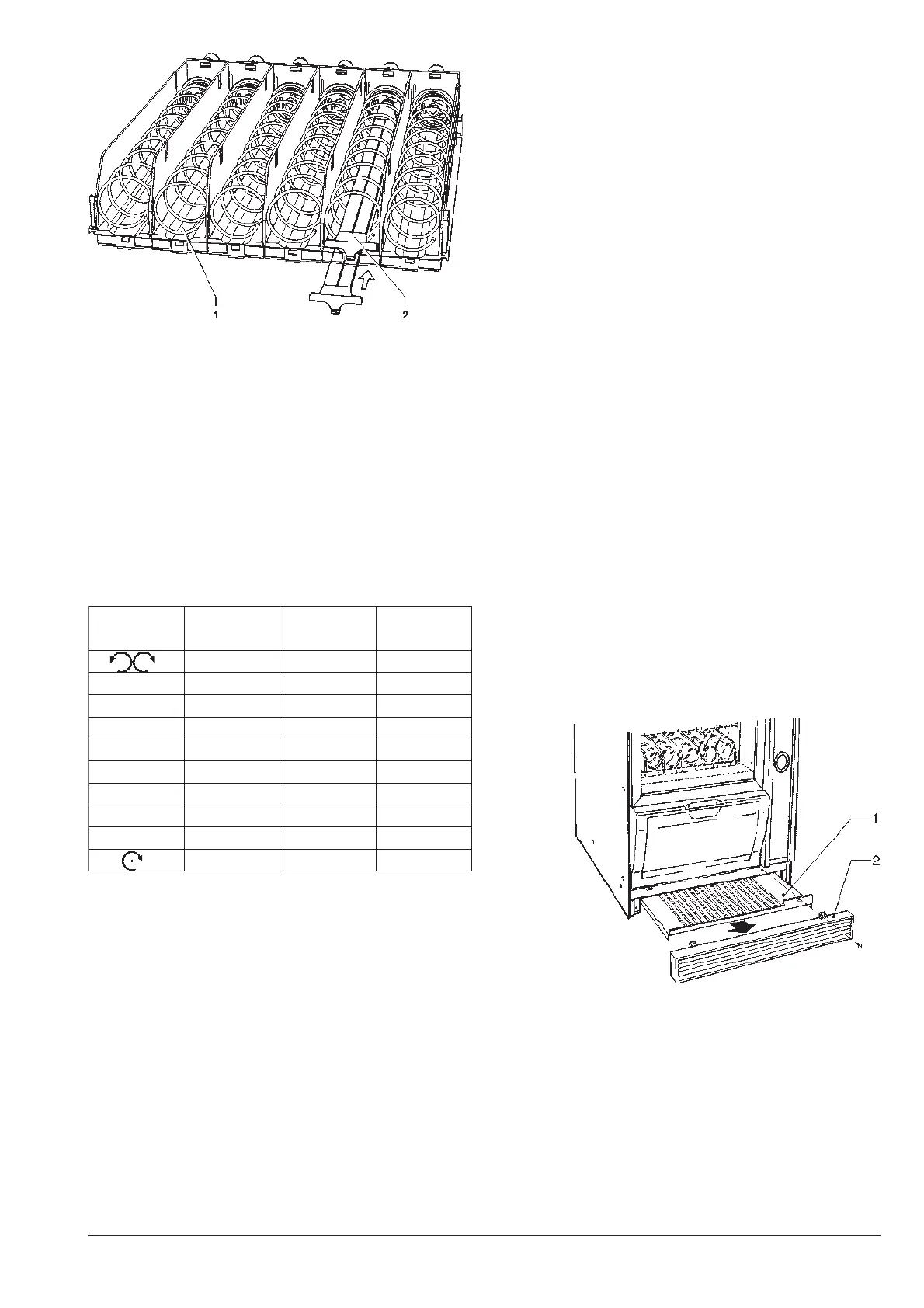

cap slides in the compartment channel.

The spirals can be positioned with 22,5 degree steps by

pulling them towards the front and rotating them in the

direction of ejection.

Normally, the products can be dispensed without any

problems when the spiral end is in the lower centre posi-

tion.

The maximum size (see Fig. 6) and the number of prod-

ucts, the pitch and the direction of rotation of the spirals are

shown in the following table.

The machine is supplied with a table indicating the opti-

mum setting for the different product types.

The configuration can be changed following the indications

of the relevant chapter.

HYGIENE AND CLEANING

According to current health and safety regulations, the

operator of vending machines is responsible for their

hygiene and cleaning.

The vending machine is not suitable for outdoor installa-

tion. It must be positioned in a dry room where the tempera-

ture remains between 5°C and 32°C, and not where water

jets are used for cleaning.

This vending machine should only be used to sell and

dispense packaged products that do not need refrigeration

to be preserved.

Strictly comply to the producer’s specifications regarding

storage method and expiry date for each product.

Any other use is unsuitable and thus potentially dan-

gerous.

It is advisable to use sanitising products (chlorine based

detergent or similar) to clean all surfaces even if not in

direct contact with food.

Some parts of the machine can be damaged by strong

detergents.

The manufacturer declines all responsibility for dam-

age to persons caused by the non-compliance with

current regulations.

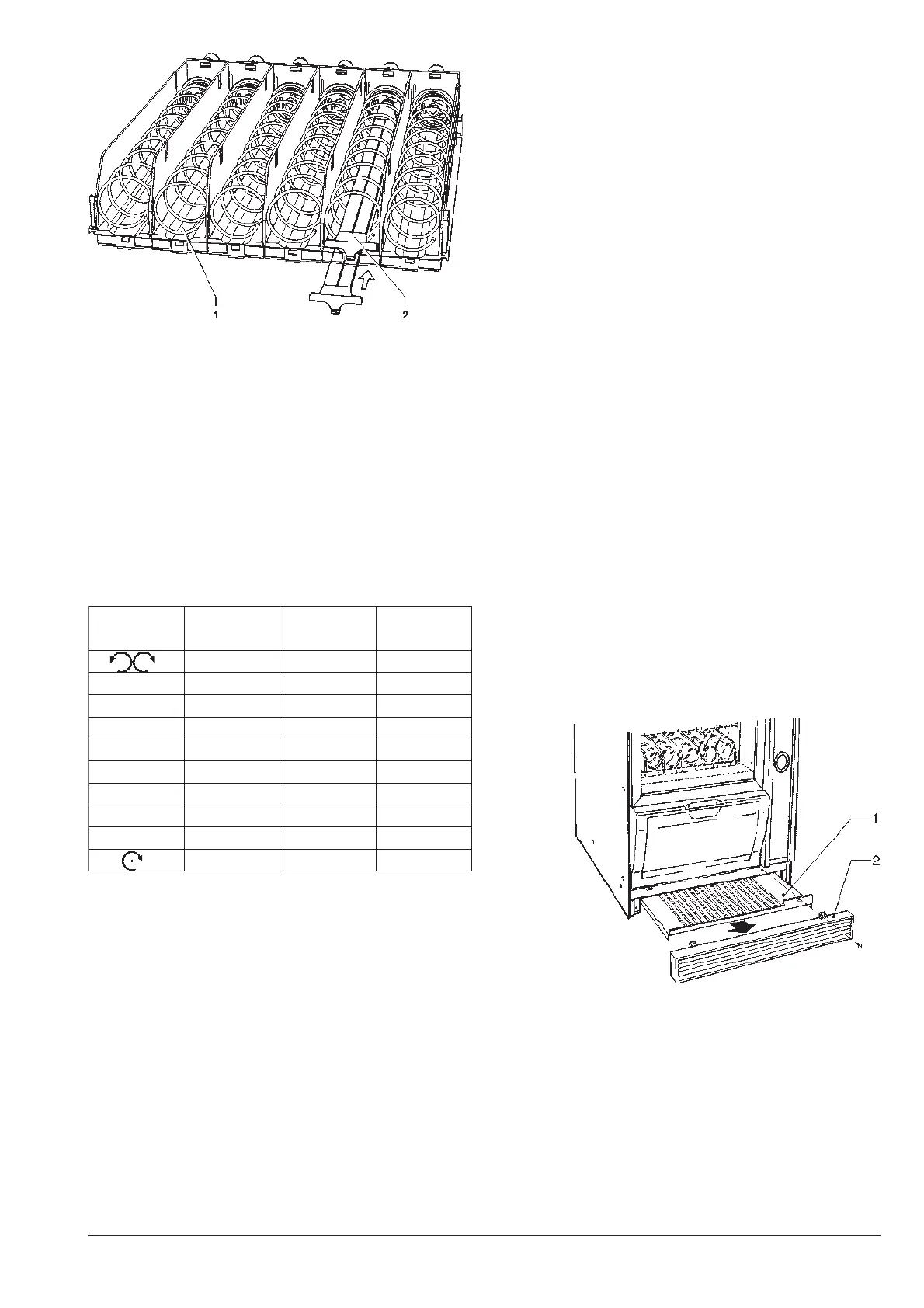

At least every six months it is necessary to clean the

ventilation grilles of the cooling system using a vacuum

cleaner or compressed air, doing as follows:

- with the vending machine disconnected from the

power supply, remove the front grille, completely

undoing the two screws;

- remove the air intake grille.

- after cleaning the grilles, reassemble everything in the

reverse order.

A

.mm

B

.mm

°N

08676

46067

45058

642401

046311

430331

036251

420291

)°081(420291+91

Under no circumstances should sprayed water be

used.

Before any maintenance operation always switch the

machine off.

The integrity of the machine and compliance with the

standards of the relevant systems must be checked at

least once a year by qualified personnel.

Fig. 8

1 - Tray groove

2 - Product support

Fig. 9

1 - Air-intake grille

2 - Front grille

Loading...

Loading...