8

© by NECTA VENDING SOLUTIONS SpA 0407 239 - 00

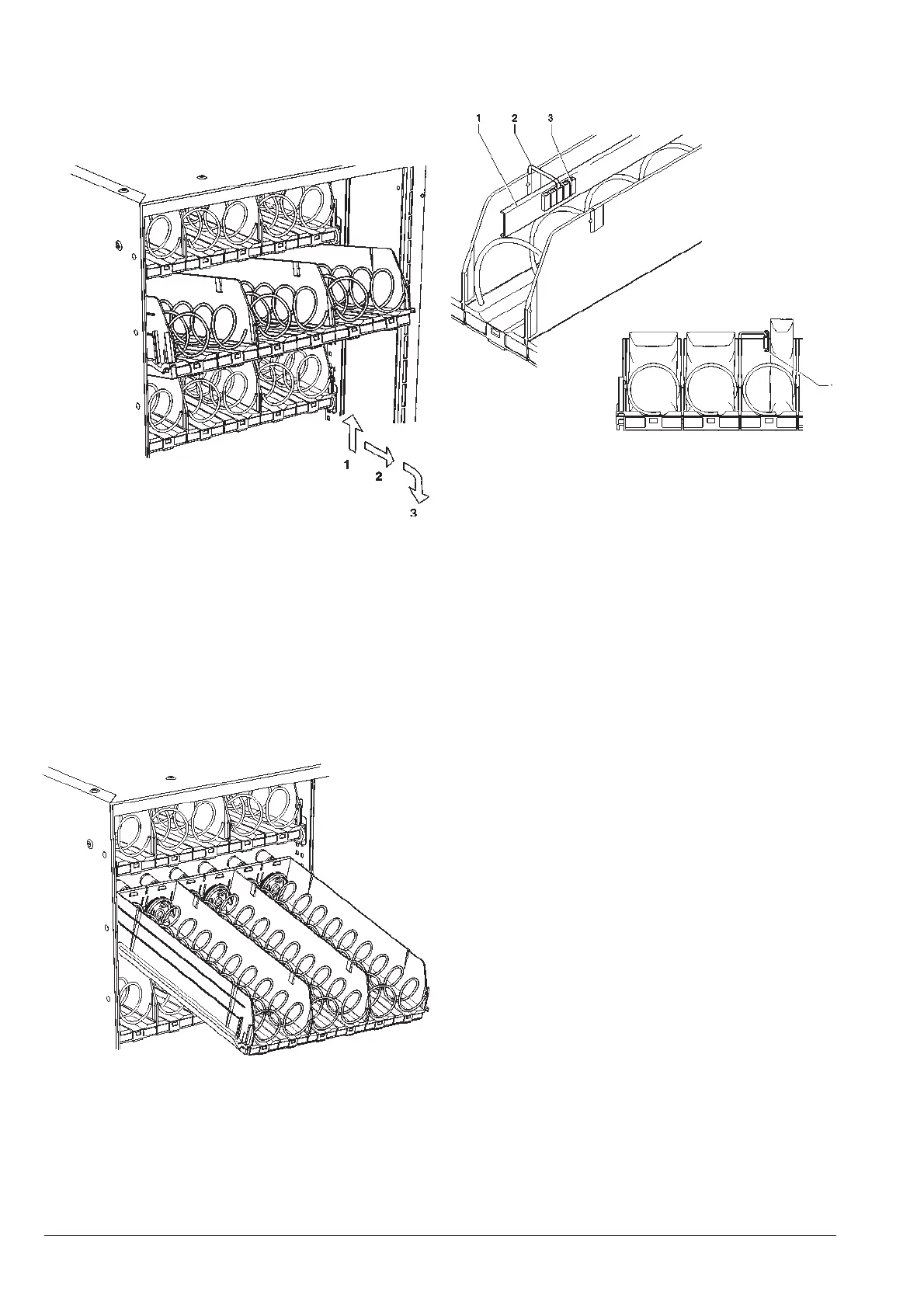

LOADING PRODUCTS

- Remove one tray at a time, lifting it and pulling it past

the retaining slide. The upper trays will tilt downwards

to facilitate loading.

Very thin products can be dispensed only using the special

spacer.

Fig. 11

- Load all products starting at the front, without inserting

products with a temperature above 30°C, ensuring that

all spaces are filled. The bottom of the product must

rest at the bottom of the compartment with the label

facing the window so that it can be identified.

All products should load easily, do not insert products

which are too large for the space.

- Push in the trays completely, ensuring that they go

past the retaining slide.

Fig. 12

Fig. 10

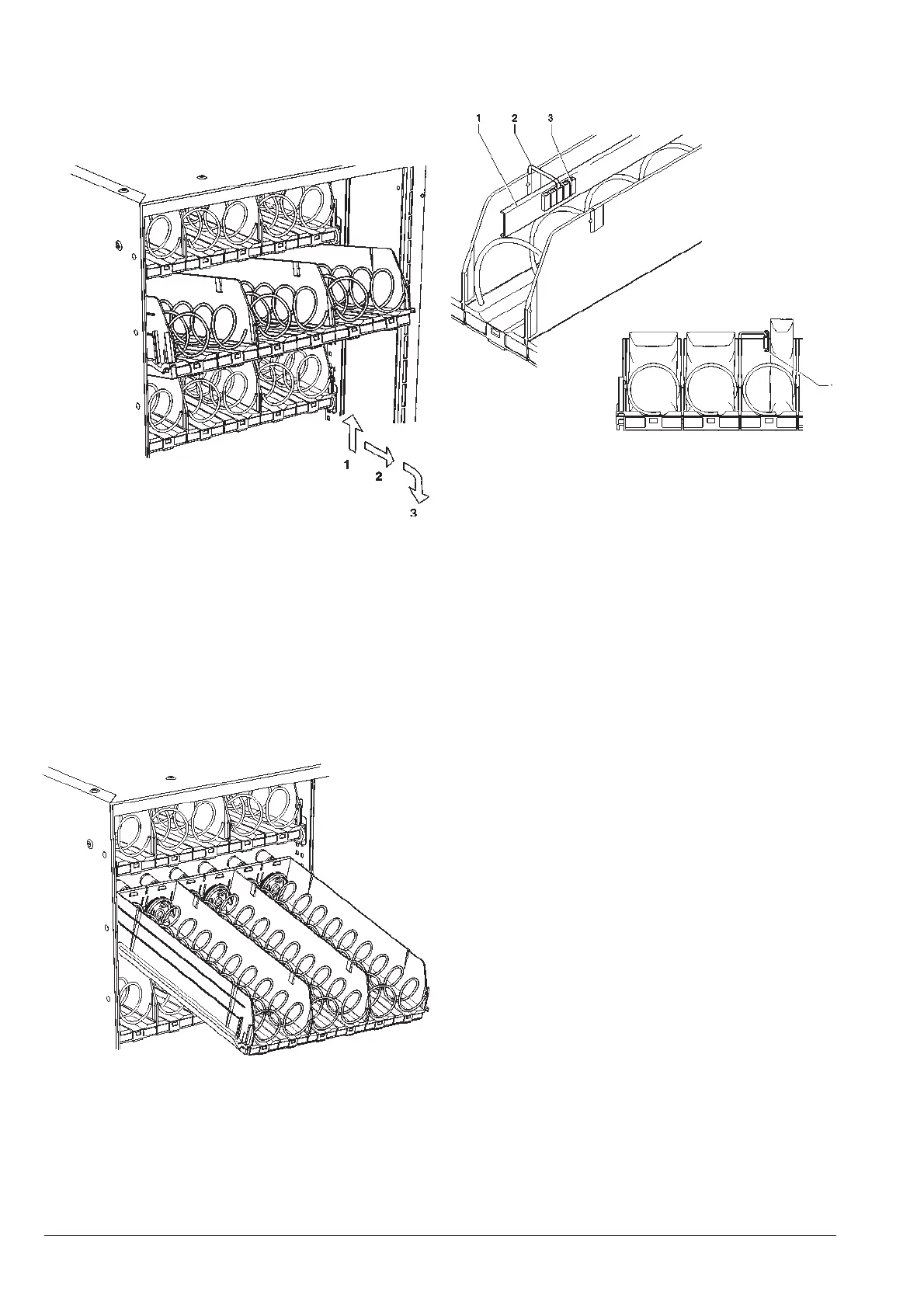

The sealed end of bags may be caught under the spiral,

preventing the free fall of the product.

Fold the seal towards the front of the unit and upwards

before inserting the product in the spiral.

More fragile products must be placed on the lower

trays to prevent damage when they drop.

START-UP

Each time the machine is started the number of trays

connected to the system are checked by the electronic

controls and indicated on the display.

Also the number of actually connected compartments is

checked.

The display will indicate in a sequence information regard-

ing:

- software version

- presence of dispensing detection photocells

- number of trays and compartments

- presence of dispensing compartment lock device

- internal sensor temperature.

NOISE LEVEL

The continuous, weighted equivalent acoustic pressure

level is below 70 dB.

1 - Product spacer

2 - Brackets

3 - Adjustment notches

Loading...

Loading...