Set-Up

Newall Measurement Systems

12

ET-UP

The Radius/Diameter function allows the operator to

display actual (radius) or twice-actual (diameter) measure-

ments for each axis. This function is generally used in

turning applications, such as the cross travel on a lathe.

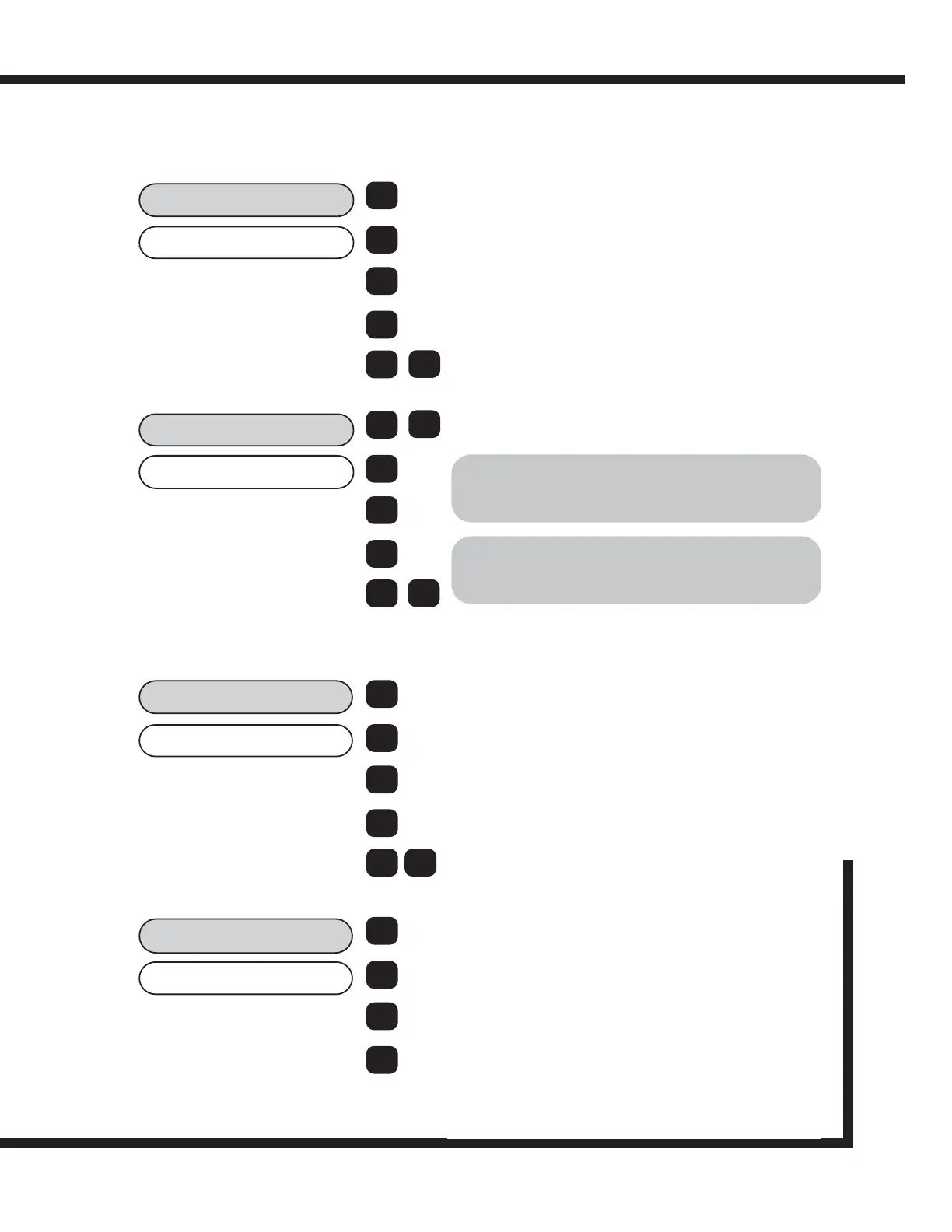

SEL. AXIS

Options: RAD

DIA

RAD/DIA

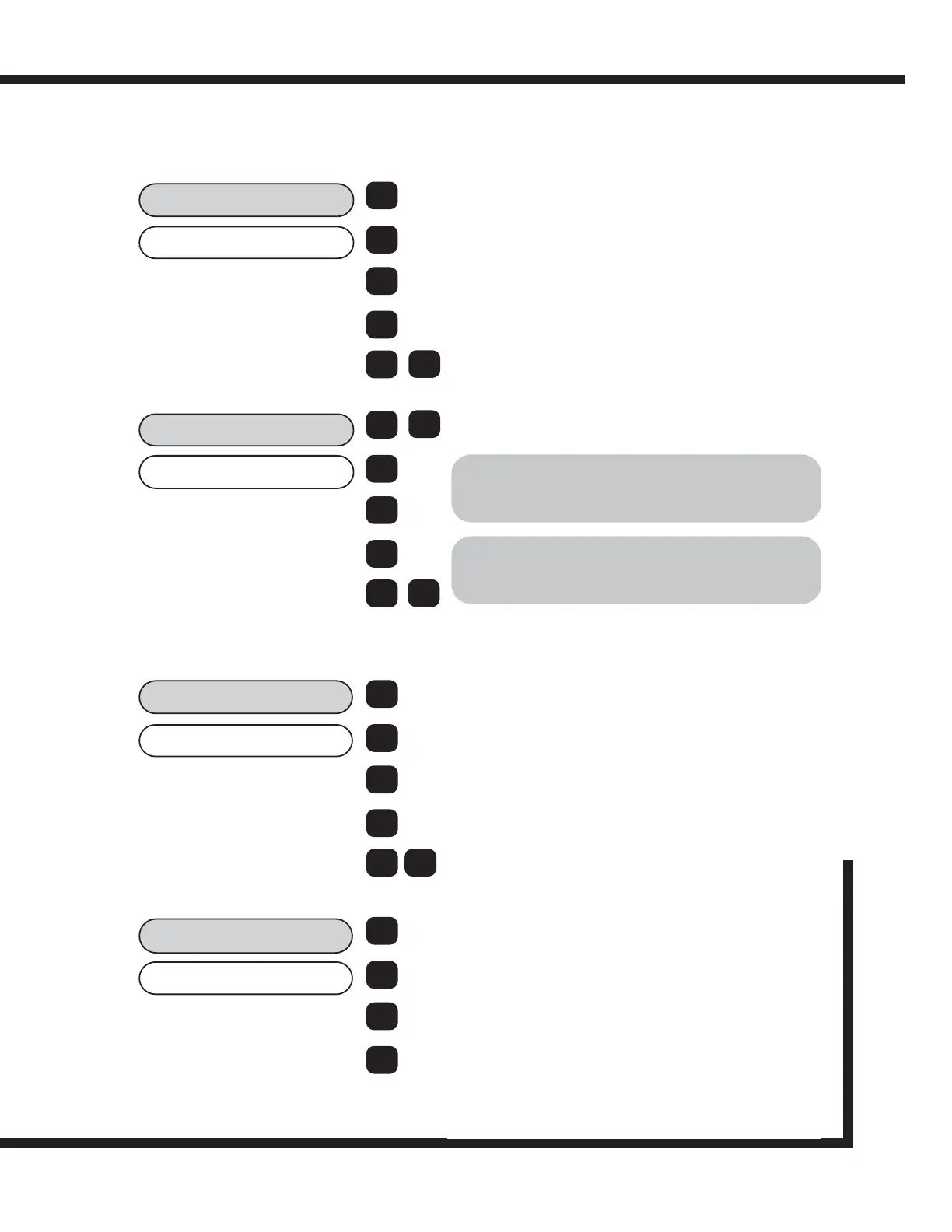

The Resolution function allows the operator to determine

the resolution for each axis.

SEL. AXIS

Options: 0.001mm (0.00005 )

0.002mm (0.0001 )

0.005mm (0.0002 )

0.010mm (0.0005 )

0.020mm (0.002 )

0.050mm (0.005 )

RESOLUTION

Toggle between Radius and Diameter using

the (AXIS) keys and select desired mode

with [ENT]

Scroll through available options for each

axis using the (AXIS) key, once all axes

read the desired resolution, select with

[ENT]

ent

ent

X

Y

Z

>

ent

ent

X

Y

Z

>

Direction allows the operator to change the direction of

travel for each axis. Changing the setting will reverse the

current direction.

EXAMPLE:

If the current setting is 0 and the travel is positive from

right to left, changing the setting to 1 will reverse the

direction to measure positive from left to right.

SEL. AXIS

Options: 0

1

ent

DIRECTION

ent

Toggle between 0 and 1 for each axis using

the (AXIS) key. When all axes read the

desired direction, select with [ENT]

X

Y

Z

>

IMPORTANT:

The Resolution available for each axis depends upon the

I/P (Input) Type established for that axis.

IMPORTANT:

The 0.001 mm (0.00005") resolution is only available

in Radius mode.

(e) Radius / Diameter

(f) Resolution

(g) Direction

Press the [ > ] key to move to the next menu option.

Press the [ > ] key to move to the next menu option.

>

Press the [ > ] key to move to the next menu option.

Linear Error Compensation allows the operator to apply a

constant correction factor to all measurements displayed.

Linear error may occur if the axis of the machine is not

running perfectly parallel to the scale (cosine error) or if the

machine is moving in an arc (Abbé errors). The causes

may be:

1. Machine wear.

2. Deflection of the machine due to weight acting on an

overhanging section.

3. Misalignment of the scale due to poor installation.

SEL. AXIS

LINEAR COMP

Select the axis to be compensated using

the axis keys

Continued overleaf...

ent

X

Y

Z

(h) Linear Error Compensation

Loading...

Loading...