Standard Functions

Newall Measurement Systems

21

STANDARD FUNCTIONS

The DP8 can store up to 199 SDM (Sub-Datum) positions, or machining steps, in non-volatile memory. The

positions remain in memory even if the power has been turned off.

Using SDM allows the operator to work to zero by calling up stored dimensions, instead of "working up" to

print dimensions. This eliminates the need to constantly refer to the print, and reduces the possibility of

scrapping parts due to mis-read dimensions. It also speeds up positioning because the operator works to

zero.

The SDMs are stored as co-ordinates relative to the absolute datum position. If the absolute datum position

changes, the SDMs will "shift" to the new datum.

SDMs provide the operator increased productivity in batch machining of parts. Once a repetitive sequence of

co-ordinates is entered into SDM, the co-ordinates can be recalled at any time. The positions remain in

memory until altered by the operator. Simply assign any SDM number 1 - 199 to each machining step. When

machining, call up each step (SDM) number and work to zero.

SDMs also reduce time for tool changes by giving the operator a fast and accurate method of returning to

locations for other operations.

SDMs also simplify machining parts with more than one datum point. The absolute zero or datum position is

determined and set. Then the secondary datum positions are entered into SDM. Once the SDM co-ordinates

are stored, the operator can display co-ordinates relative to the SDM, as well as to the absolute datum posi-

tion.

SDMs are stored by using one of the following two methods:

1

SDM NO. ?

1.2000

ABS

2.8000

sdm

sdm

zero

sdm

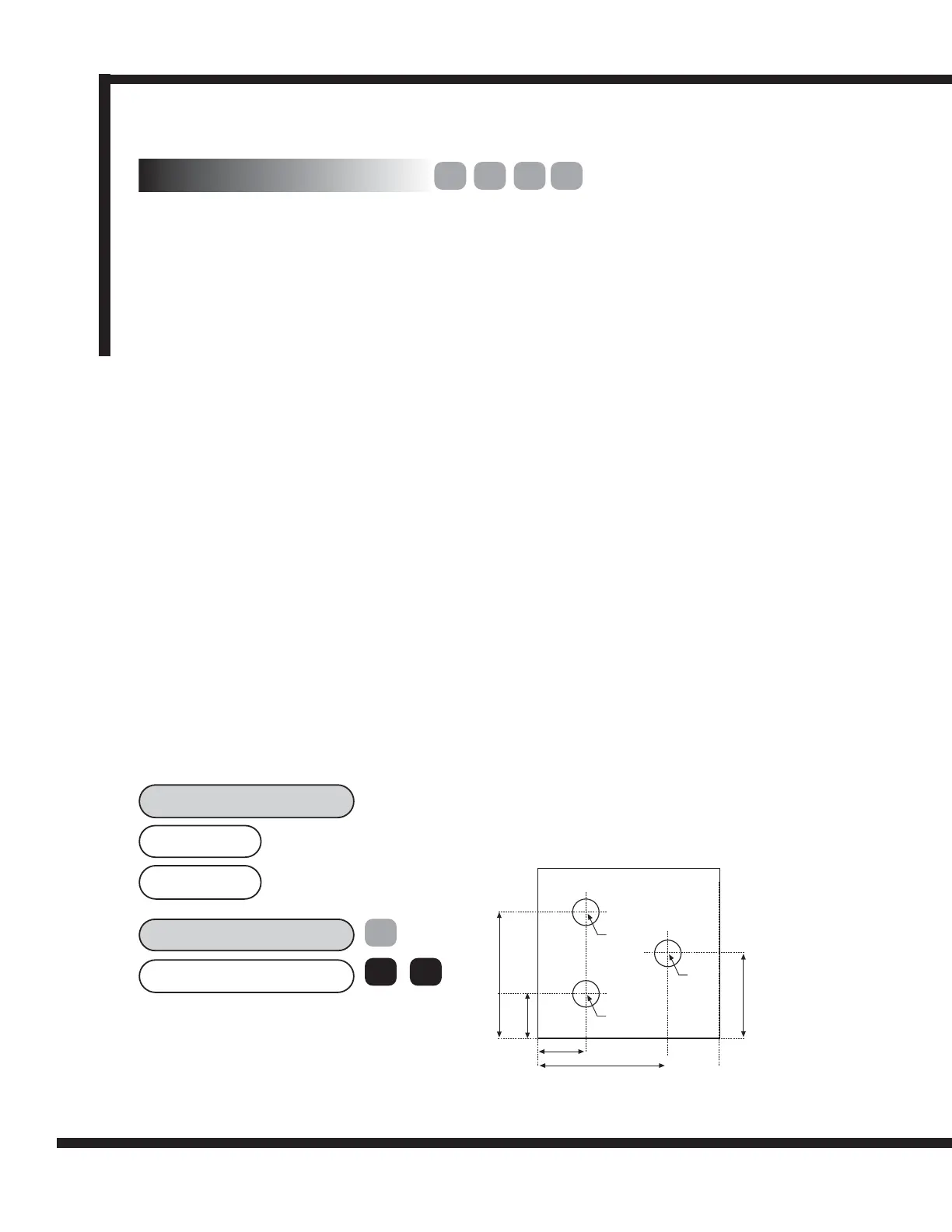

EXAMPLE:

Keystrokes for entering the following part dimension into

SDM are shown.

ent

1

SDM 1

SDM 2

SDM 3

2.800in

1.200in

1.200in

2.800in

2.000in

del.

ins.

5.4.1 Method 1 (Teach Mode)

Using this method, move the machine to the position to be stored as the SDM. Use this method to avoid

entering print dimensions via the keypad. The operator "works up" to the dimensions on the print the first

time. Each position is stored in SDM by pressing the Teach key [ SDM ZERO ], once an SDM number has

been selected.

5.4 Sub datums (SDM)

X

Y

Y

X

Loading...

Loading...