Standard Functions

Newall Measurement Systems

23

STANDARD FUNCTIONS

5.4.2 Method 2 (Manual Mode)

In this example, known SDM co-ordinates are entered via the keypad without moving the machine. SDM

co-ordinates must be entered relative to the absolute datum position. In other words each axis should be set to

zero prior to programming sub-datums

1

SDM NO. ?

sdm

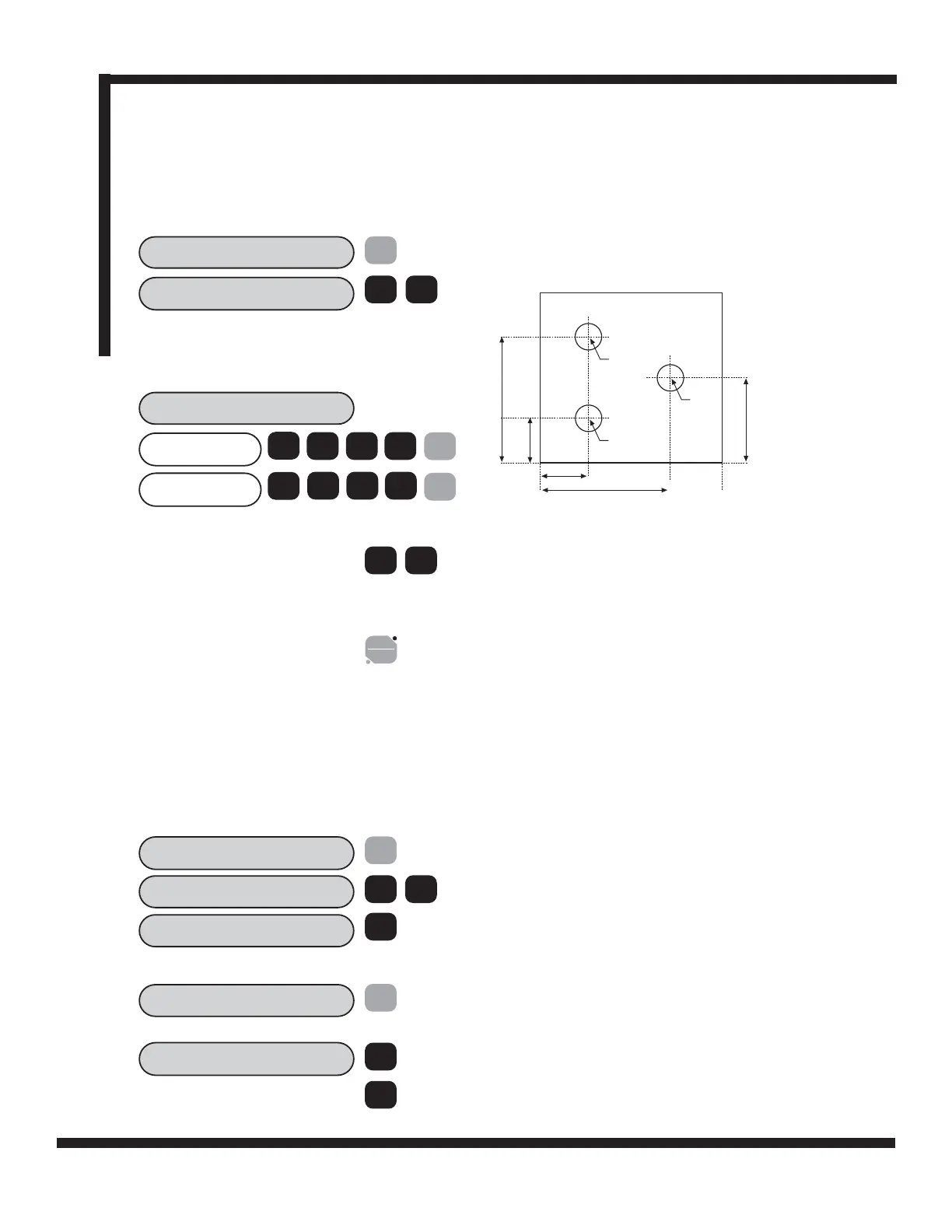

EXAMPLE:

Keystrokes for entering the following part dimension into

SDM are shown.

ent

1

1.2000

SDM 1

2.8000

1 2

.

Select the first SDM number using the

[SDM] or arrow keys.

Select the desired AXIS, enter the dimen-

sion and confirm with SDM.

Scroll through the next SDM by using the

arrow keys. Alternatively, use the [SDM] key

to select a new SDM. Enter the new

coordinates via the keypad.

Repeat procedure for SDM2 and SDM 3.

2 8

.

<

>

To exit SDM function, select ABS/INC

5.4.3 Job Numbers

This function enables a group of sub datums to be identified by a number at the beginning of the group, and

an end marker at the end of the group.

Once a series of sub datums has been entered it is possible to enter the Job Number and End Marker. From

a selected Sub Datum proceed as follows in the example below:

(a) To insert a Job Number

SDM NO?

sdm

ent

Select the first Sub Datum in the sequence

to be grouped e.g. SDM10

SDM 1

SDM 2

SDM 3

2.800in

1.200in

1.200in

2.800in

2.000in

abs

inc

INS SDM

Press INS key.

>

ins.

1

0

INS JOB?

ent

Press the arrow key to display Insert Job.

Confirm with [ENT].

10

SDM 10

sdm

sdm

NOTE: The axis displays will change to show the current

position relative to the SDM.

X

Y

Y

X

Loading...

Loading...