Mill Functions

Newall Measurement Systems

28

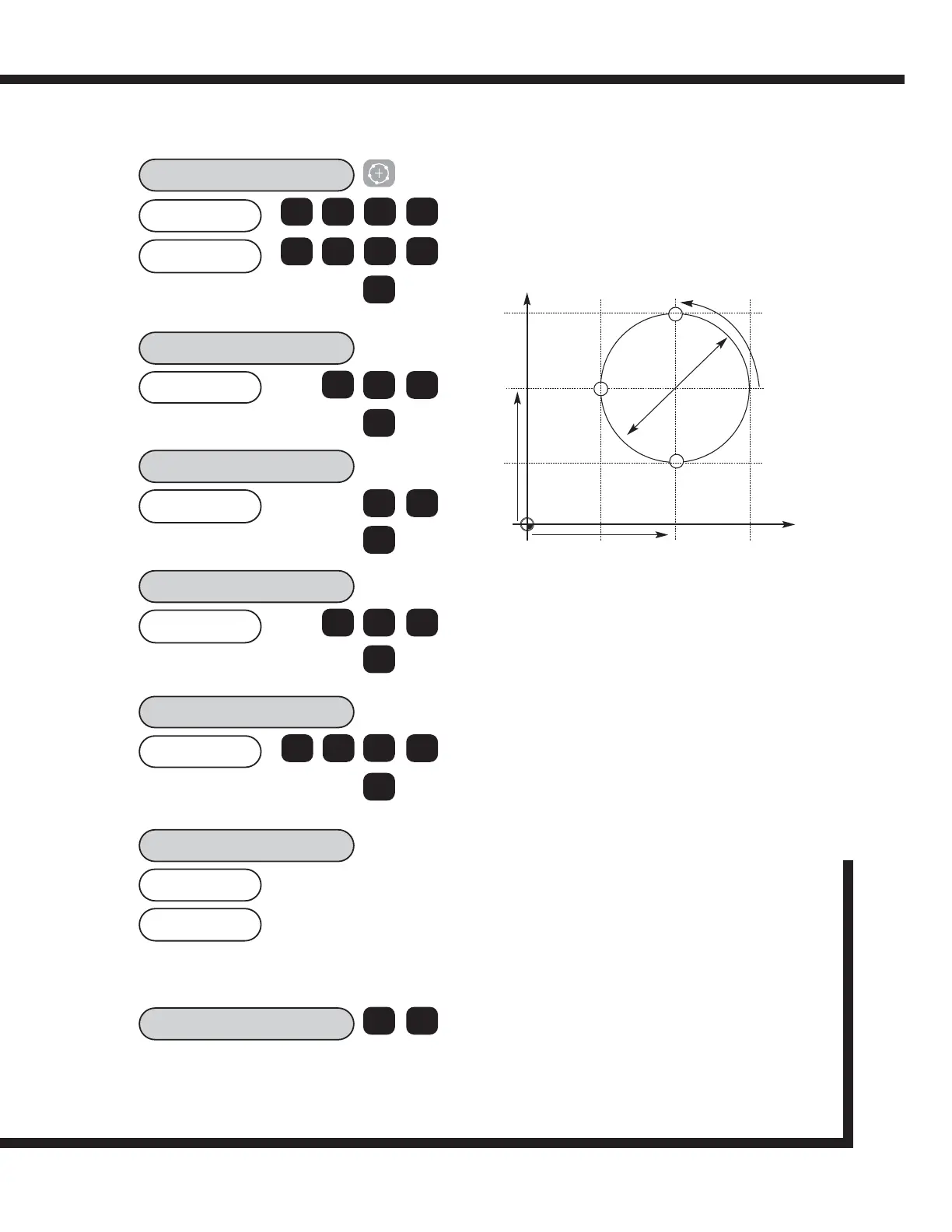

EXAMPLE:

The keystrokes for entering the following bolt hole circle

are shown. X and Y axes are assumed at Absolute Zero.

50.0000

CENTRE?

50.0000

X

Z

The bolt pattern will be calculated from the 3 o'clock

position, counter-clockwise. The starting angle is the angle

from the 3 o'clock position to the first hole. Enter the angle

as a negative value if it is given as clockwise from 3

o'clock.

The ending angle is calculated from the 3 o'clock position

counter-clockwise to the last hole. If the pattern is a

complete circle, enter the same ending angle as starting

angle.

40.0000

DIA?

0

ent

>

3

NO HOLES

3

ent

>

90.000

ST ANG?

0

ent

>

270.000

END ANG?

7

ent

>

-50.000

HOLE 1

>

-70.000

9

2

Position the X and Y axes until both displays

read Zero. This is the first hole location.

HOLE 2

< >

Use the arrow keys to display co-ordinates for

subsequent holes in the routine. Work to zero for each

hole location.

X

Y

90

O

50

50

0

0

70

30

30 70

D 40.0

(50,70)

(50,30)

(30,50)

NOTE: The 2 axes mill operations are similar to the 3

axes version except that the PCD is not plane

selectable.

0

ent

ent

5

0

5

0

4

NOTE:

The numbers appear as negative numbers because the

operator works to 0,0. According to the above drawing,

the first hole is in a positive position for both X and Y.

Therefore, the display will count up to zero when the axes

are moved. If these numbers do not appear, exit the PCD

function and check the axes readings in X and Y. You will

find that the Hole 1 dimensions are the sum of the

absolute positions plus the calculated positions. The hole

locations will always reference 0,0.

Loading...

Loading...