Mill Functions

Newall Measurement Systems

R

29

MILL FUNCTIONS

EXAMPLE:

The keystrokes for entering the following

arc are shown.

ARC -- XY

The DP8 calculates positions for rough machining an arc or radius. The message display prompts the user

for various parameters needed to do the calculations. Once the calculations are complete, the axis displays

show the co-ordinates, which are point-to-point positions along the arc. The operator moves to Zero for each

point position.

It is possible to machine along the inside or outside of the arc. Arc Contouring can be used in three planes:

XY, XZ or YZ. The vertical planes (XZ, YZ) are only available if using a 3-axes DP8 Mill.

The ARC function assumes an arc of 180°

or less. For a 180

o

arc, the routine will cal-

culate the arc in a counter-clockwise direc-

tion, assuming standard XYZ movement.

2.3700

CENTRE?

2

ent

4.0000

RADIUS?

4

ent

Options: ARC - XY

ARC - XZ

ARC - Y Z

>

ent

Scroll through available options using the

arrow key and select desired plane with

[ENT].

1.4900

X

Y

. 3 7

1

ent

. 4 9

1.3200

S T. PT?

1

ent

5.3700

X

Y

. 3 2

5

ent

. 3 7

6.2200

END. PT?

6

ent

2.5100

X

Y

. 2 2

2

ent

. 5

1

>

>

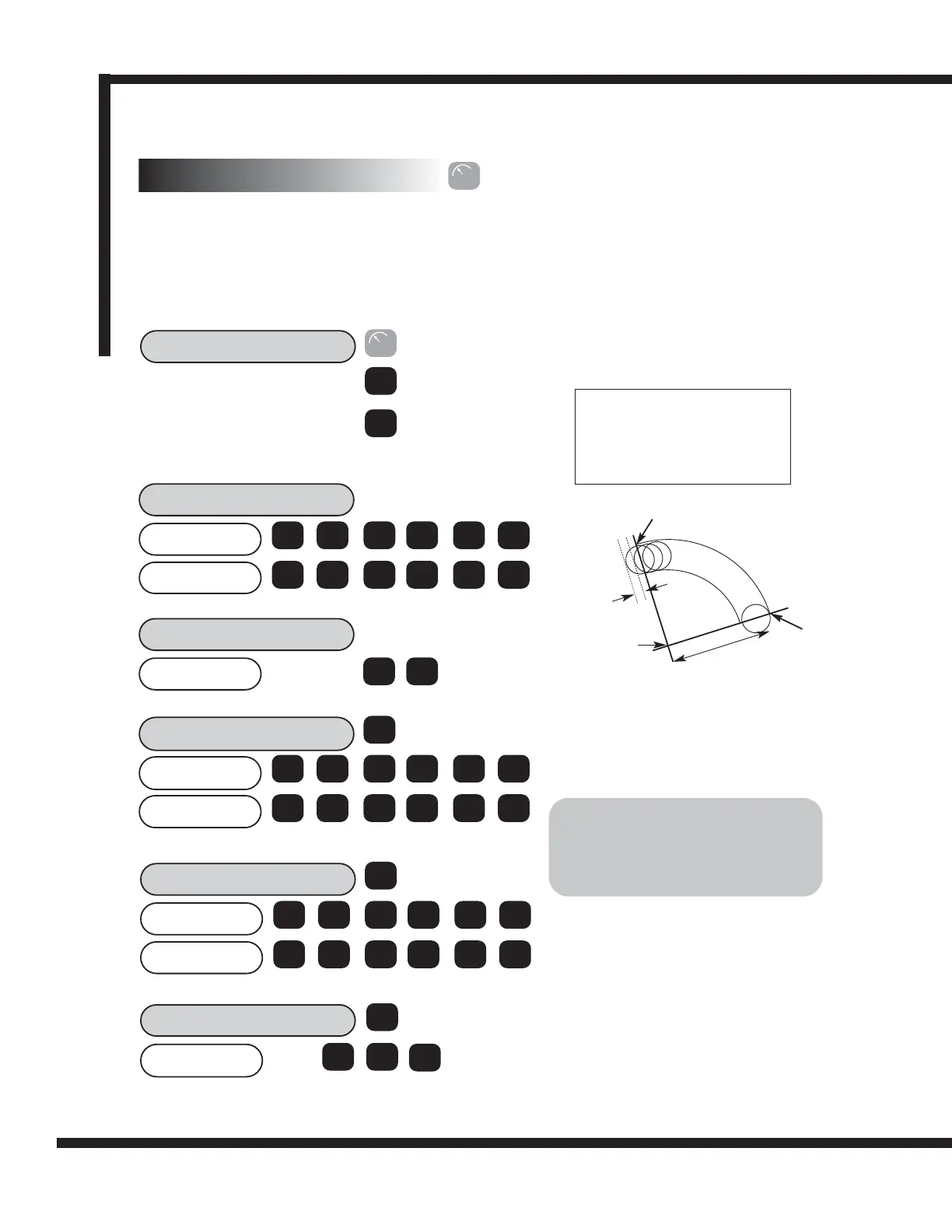

Centre: X2.370” Y1.490”

Radius: 4.0”

Start Point: X1.320” Y5.370”

End Point X6.220” Y2.510”

Tool Diameter: 0.5”

Internal/External: Internal (RAD-TOOL)

Maximum Cut: 0.1”

Radius

Centre

Maximum Cut

Start Point

End Point

IMPORTANT!

If the parameters entered in START

POINT and END POINT are inconsistent,

the CENTER and RADIUS figures

override the inconsistent parameters.

0.5000

TOOL DIA

5

ent

>

.

6.2 Arc Contouring

R

Loading...

Loading...